Feb . 15, 2025 19:24 Back to list

measuring tools in metal work

Accurate measurements are the backbone of successful metal work, ensuring that each piece fits together seamlessly and functions as intended. This critical aspect of metal craftsmanship relies on precise measuring tools, which are indispensable in both industrial applications and artisanal projects. Here, we delve into the world of measuring tools essential for metal work, dissecting their functions, significance, and the way they shape exceptional craftsmanship.

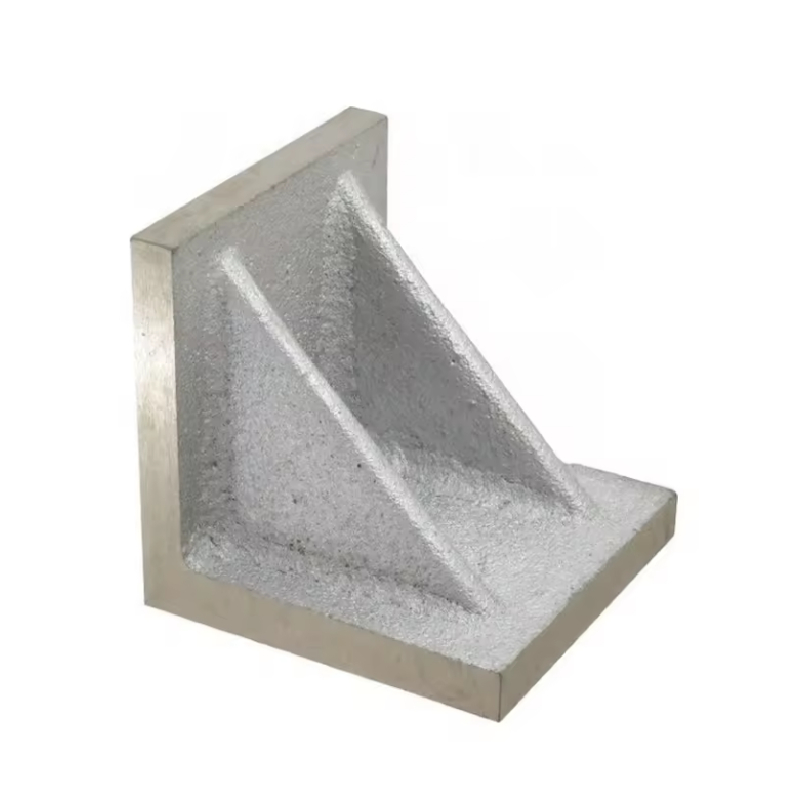

Angle measuring tools like bevel protractors allow for the accurate measurement and transfer of angles, a necessary capability for creating joints and components that require precise angular alignments. Their application proves indispensable in specialized tasks such as bevel cutting and component alignment in complex metal structures. The paramount importance of maintaining these tools cannot be understated. Regular calibration and care—shielding tools from rust, regular cleaning, and storing in protective cases—ensure their longevity and sustained accuracy. Knowledgeable workers understand that well-maintained tools not only provide precise measurements but also extend the life of the tools, providing continuity in quality output. Establishing trustworthiness and authority within your metalwork projects is closely linked to the consistent use of these measuring tools. A workshop equipped with well-calibrated, precision tools demonstrates a commitment to quality and professionalism. Clients and stakeholders are reassured by the reliability and excellence achieved through exceptional craftsmanship, supported by premium tools. Integrating advanced technologies, such as digital interfaces and CNC machine integrations, further exemplifies a commitment to excellence in metalwork. These modern adaptations not only streamline processes but also enhance precision, enabling metalworkers to push the boundaries of innovation and creativity while maintaining the utmost fidelity to prescribed measurements. Ultimately, mastery over measuring tools in metal work is a testament to one's skill, professionalism, and adherence to best practices. It reinforces the metalworker's role as an artisan committed to delivering precise, high-quality results. By understanding, applying, and maintaining these tools correctly, metalworkers solidify their reputation as experts in their field, contributing to a legacy of excellence and trust.

Angle measuring tools like bevel protractors allow for the accurate measurement and transfer of angles, a necessary capability for creating joints and components that require precise angular alignments. Their application proves indispensable in specialized tasks such as bevel cutting and component alignment in complex metal structures. The paramount importance of maintaining these tools cannot be understated. Regular calibration and care—shielding tools from rust, regular cleaning, and storing in protective cases—ensure their longevity and sustained accuracy. Knowledgeable workers understand that well-maintained tools not only provide precise measurements but also extend the life of the tools, providing continuity in quality output. Establishing trustworthiness and authority within your metalwork projects is closely linked to the consistent use of these measuring tools. A workshop equipped with well-calibrated, precision tools demonstrates a commitment to quality and professionalism. Clients and stakeholders are reassured by the reliability and excellence achieved through exceptional craftsmanship, supported by premium tools. Integrating advanced technologies, such as digital interfaces and CNC machine integrations, further exemplifies a commitment to excellence in metalwork. These modern adaptations not only streamline processes but also enhance precision, enabling metalworkers to push the boundaries of innovation and creativity while maintaining the utmost fidelity to prescribed measurements. Ultimately, mastery over measuring tools in metal work is a testament to one's skill, professionalism, and adherence to best practices. It reinforces the metalworker's role as an artisan committed to delivering precise, high-quality results. By understanding, applying, and maintaining these tools correctly, metalworkers solidify their reputation as experts in their field, contributing to a legacy of excellence and trust.

Latest news

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

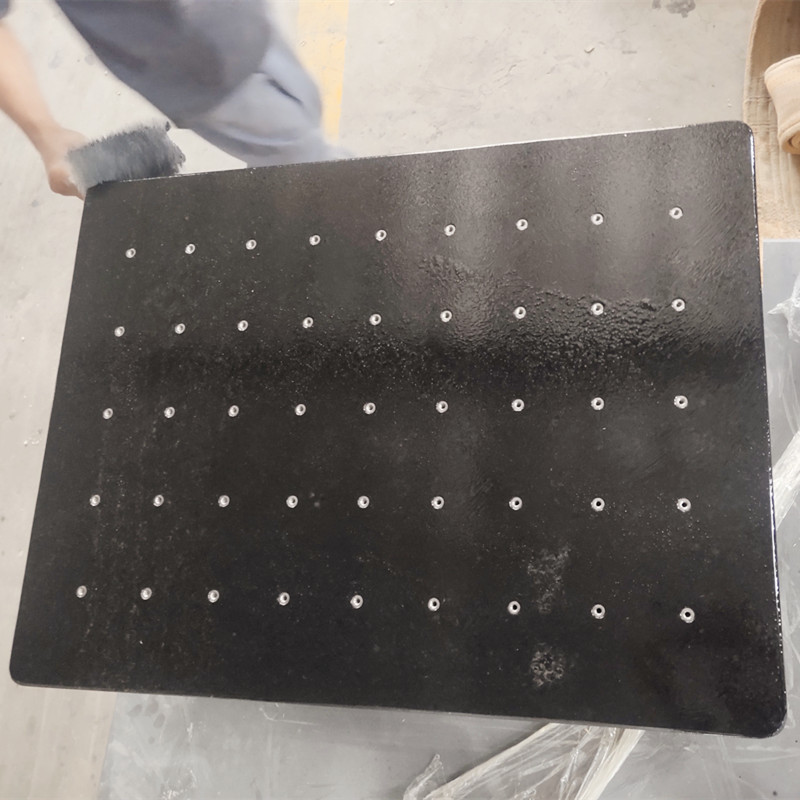

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS