光学合成画像レベル

製品説明

- 1.アプリケーション

光学合成画像レベルは、平面および円筒面の水平方向の勾配、工作機械または光学機械機器のスライドウェイまたはベースの平面度および真直度、および機器の設置位置の正確さの測定に広く使用されています。

- 2.技術データ

(1)各目盛値:…0.01mm/m

(2)最大測定範囲:...0〜10mm/m

(3)許容差:1mm/1メートル以内・・・0.01mm/m

全測定範囲内...0.02mm/m

(4)作業面の平面偏差…0.0003mm/m

(5)水準器の各目盛値…0.1mm/m

(6)作業面(LW):...165 48mm

(7)機器の正味重量:2kg

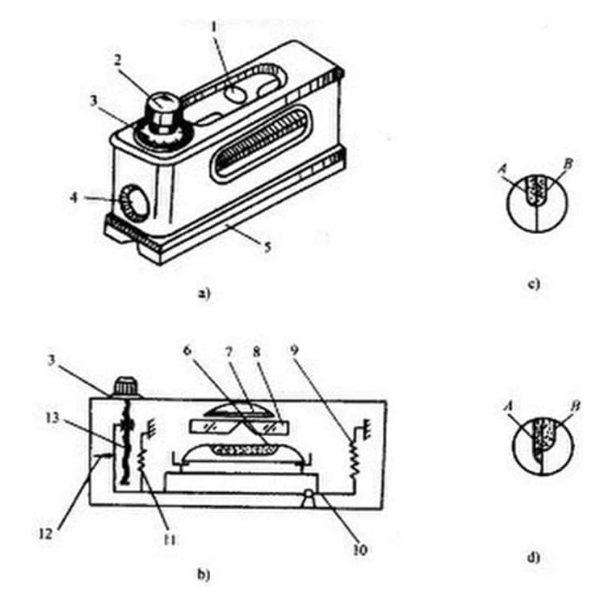

- 3.機器の構造:

複合画像レベルは、主に、微調整ネジ、ナット、目盛り付きディスク、水準器、プリズム、拡大鏡、レバー、および平面と V 字型の作業面を備えたベースなどの部品で構成されています。

- 4.動作原理:

複合画像水準器はプリズムを使用して水準器内の気泡画像を複合・拡大し、読み取り精度を高め、レバーとマイクロネジ伝達システムを使用して読み取り感度を高めます。したがって、0.01mm/mの勾配を持つワークピースであれば、複合画像水準器で正確に読み取ることができます(複合画像水準器内の水準器は主にゼロを示す役割を果たします)。

- 5.操作方法:

複合画像レベルを測定ワークピースの作業面上に置くと、測定ワークピースの勾配により 2 つの気泡画像が一致しなくなります。2 つの気泡画像が一致するまで目盛り付きディスクを回転させると、すぐに読み取り値が得られます。測定ワークピースの実際の勾配は、次の式で計算できます。

実際の勾配=勾配値支点距離ディスクの読み取り

Fox の例: ディスク読み取り: 5 段階のグラデーション。この合成画像レベルは、グラデーション値と支点距離で Fox 化されているため、グラデーション値は 0.01mm/m、支点距離は 165mm です。

つまり、実際の勾配=165mm 5 0.01/1000=0.00825mm

- 6.操作上の注意:

(1)使用前にガソリンで油汚れを拭き取り、その後吸水ガーゼで拭いてください。

(2)温度変化は計測器に大きな影響を与えるため、誤差を避けるために熱源から分離する必要がある。

(3)測定中は、2つの気泡像が完全に一致するまで目盛り付きディスクを回転させ、正負両方向の測定値を取得します。

(4) If the instrument is found with in correct zero position, it may be adjusted; Put the instrument on a stable table and rotate the graduated disc to set the tow air bubble images coincide to get first reading a; Then turn the instrument by 180o and put back to its original place. Ra-rotate the graduated disc to get the tow air bubbles coincide to get the second reading b. So 1/2 (α +β ) is the zero deviation of the instrument. Loosen the three supporting screws on the graduated disc and press lightly by hand the embossed adjusting cap; Rotate the disc by 1/2 (α +β) to get the zero deviation and the point line composite; At last fasten the screws.

(5)作業後は、機器の作業面を清掃し、酸を含まない無水防錆油と防錆紙でコーティングし、木箱に入れて清潔で乾燥した場所に保管してください。

Hot Tags: Optical Composite Image Level Optical Composite Image Level suppliers China Optical Composite Image Level Optical Composite Image Level factory stable Optical Composite Image Level

製品パラメータ

技術的パラメータ

- プレート値ダイヤル 0.01 mm/m

- 測定範囲 0~10ミリメートル/メートル

- Parent-child error within ± 1mm/m+0.01 mm/m

- The parental error within the entire measurement range is ± 0. 02 millimeters/meter

- ベンチ平坦度偏差0.003mm

- セル値累積基準 0.1 ミリメートル/メートル

- オフィスデスクサイズ 165 x 48 ミリメートル

- 正味重量 2.2 キログラム

Optical Composite Image Level Maintenance: Antirust Oil & Storage Tips

Proper maintenance ensures your optical composite image level retains its 0.01mm/m precision and durability. Follow these steps to protect its prism technology and mechanical components:

1. Daily Cleaning for Surface Protection

After use, wipe working surfaces (V-groove, edges, lenses) with isopropyl alcohol on a lint-free cloth to remove oils and dust. Use a soft brush for stubborn debris—never abrasives, which can scratch optical parts or damage metal coatings. This preserves the precision ground surfaces (Ra ≤ 0.1μm) critical for accurate readings.

2. Routine Antirust Care for Metal Parts

While the granite base resists corrosion, metal components (screws, levers, hinges) need protection. Apply Storaen’s non-acidic anti-rust oil every 3 months or after moisture exposure:

Apply thinly to threads and pivots with a dropper, avoiding pooling on granite/lenses.

Prevents seizing: Maintains lever mechanism sensitivity (0.001mm precision) for cylindrical slope measurements.

3. Optimal Storage Practices

Store in the included hard case or a dry cabinet to avoid temperature/humidity damage:

Environment: 10°C–30°C, <60% humidity to prevent lens condensation and optical distortion.

Positioning: Lay flat or upright in padded slots; never under heavy objects to avoid misaligning the optical system.

Long-term storage: Reapply anti-rust oil and add a silica packet; inspect 24 hours before use, verifying zero position via 180° rotation calibration.

4. Monthly Functional Inspections

Check performance regularly to ensure reliability:

Bubble clarity: Confirm the composite bubble image aligns smoothly without blur.

Lever movement: Test micro-screws for smooth rotation—stiffness signals needed lubrication.

Flatness check: Use a reference plate to validate factory-calibrated flatness (±0.0003mm/m).

5. Storaen’s Support for Longevity

Leverage our expert services to maintain peak performance:

Factory recalibration: Restores 0.01mm/m precision via ISO-certified equipment for critical applications.

Genuine parts: Replacement components ensure compatibility and preserve original accuracy.

By following these steps, your Storaen optical composite image level will deliver consistent precision for industrial alignment tasks, backed by our 30+ years of engineering expertise.

Zero Position Calibration of Optical Composite Image Level: 180° Rotation Method Explained

Accurate zero calibration is vital for your Storaen optical composite image level to maintain its 0.01mm/m precision and ±0.0003mm/m flatness. The 180° rotation method eliminates subtle optical or mechanical shifts, ensuring reliable measurements in critical tasks like CNC machine alignment or aerospace component inspection. Here’s a streamlined, step-by-step guide:

1. Why Calibrate?

Impacts, vibrations, or temperature fluctuations can shift the level’s zero reference, leading to measurement drift. Calibration realigns the bubble vial with the tool’s optical prism and lever system, ensuring consistent baselines for industrial applications where 0.001mm deviations are unacceptable—such as verifying machine tool guides or structural frameworks.

2. Setup Requirements

Storaen optical composite image level (featuring a V-grooved base and micro-adjusting screw)

Certified precision reference flat (e.g., our Storaen granite surface plate, with flatness ≤0.0002mm/m)

A clean, vibration-free workbench in a temperature-stabilized environment (18°C–22°C recommended)

3. Step 1: Initial Measurement

Place the level lengthwise on the reference flat, aligning the V-grooved base with the flat’s central axis. Rotate the micro-adjusting screw until the composite bubble image—created by the 45° prism system—perfectly overlaps in the viewfinder. Record this initial scale reading (A), which reflects the current deviation from true zero.

4. Step 2: 180° Rotation & Second Reading

Carefully flip the level 180° end-to-end while maintaining its longitudinal orientation on the flat (avoid any lateral movement). Adjust the micro-screw again to align the bubble image and record the new reading (B). The difference Δ = |A - B| indicates zero position error; ideal values for Storaen levels should be ≤0.005mm/m.

5. Step 3: Error Correction & Verification

Calculate the target zero position as the midpoint: C = (A + B)/2. Loosen the protective cap on the zero-adjustment screw (typically located near the bubble vial), rotate the screw until the scale reads C, then retighten. Repeat Steps 3–4 until Δ ≤0.002mm/m, ensuring minimal residual error.

6. Pro Tips for Precision

Triple-Check Consistency: Perform 3 calibration cycles, especially after transporting the level or working in environments with temperature swings, to ensure repeatable results.

Lubricate Moving Parts: Apply a drop of Storaen’s non-acidic oil to the micro-screw before adjustment to ensure smooth, backlash-free operation and prevent binding.

Environmental Control: Avoid calibrating near heat sources or drafts, as even minor temperature gradients can affect the granite base’s dimensional stability and introduce errors.

7. Storaen’s Calibration Support

Every Storaen optical composite image level includes a NIST-traceable calibration certificate, but quarterly in-field checks are recommended for heavy use. Our support includes:

Factory Recalibration: Restoring original 0.01mm/m accuracy using laser interferometers for high-stakes applications.

Genuine Spare Parts: Readily available adjustment screws and maintenance kits for long-term usability.

Video Tutorials & Expert Guidance: Step-by-step videos and engineer support to assist with on-site calibration procedures.

Final Notes

Mastering the 180° rotation method ensures your Storaen optical composite image level delivers the precision required for cylindrical slope measurements, machine tool flatness checks, and other critical alignments. With proper calibration, this tool, backed by our 30+ years of engineering expertise, becomes an indispensable asset in your quality control workflow, ensuring every measurement is as reliable as the first.

関連している 製品

関連ニュース

Thread Plug Gauge Requires Careful Handling

In the world of manufacturing and engineering, precision is non-negotiable—especially when it comes to threads, which are critical components in machinery, construction, and everyday products.

Surface plate calibration

In today's world, where precision and accuracy are crucial in various industries, the use of granite inspection tables and granite surface plates has become increasingly popular.

Ring Gauge Ensures Machining Accuracy

In the world of precision engineering, manufacturing, and quality control, accuracy is the cornerstone of reliability.