9月 . 23, 2024 06:57 Back to list

workbench welding table

The Ultimate Guide to Workbench Welding Tables

Welding is a critical skill in various industries, from construction to artistry. A crucial component of successful welding is the workbench, specifically designed to accommodate the nuances and requirements of welding tasks. A dedicated welding table not only enhances the efficiency of the welding process but also ensures safety and precision. This article explores what makes workbench welding tables essential for any welder, whether a professional or a hobbyist.

Importance of a Welding Table

A welding table serves as the foundation for all welding activities. It provides a stable, flat surface that is essential for accurate welds. A well-constructed welding table can handle the weight of heavy materials and withstand the intense heat produced during the welding process. This capability is crucial, as it reduces the risk of warping and ensures that components remain square and true.

Moreover, dedicated welding tables often come equipped with features specifically designed to facilitate welding tasks. These include slots for clamps, built-in measuring tools, and even pre-drilled holes to hold workpieces securely in place. By providing these features, welding tables optimize both the speed and quality of the welding process, making them invaluable in workshop environments.

Materials and Construction

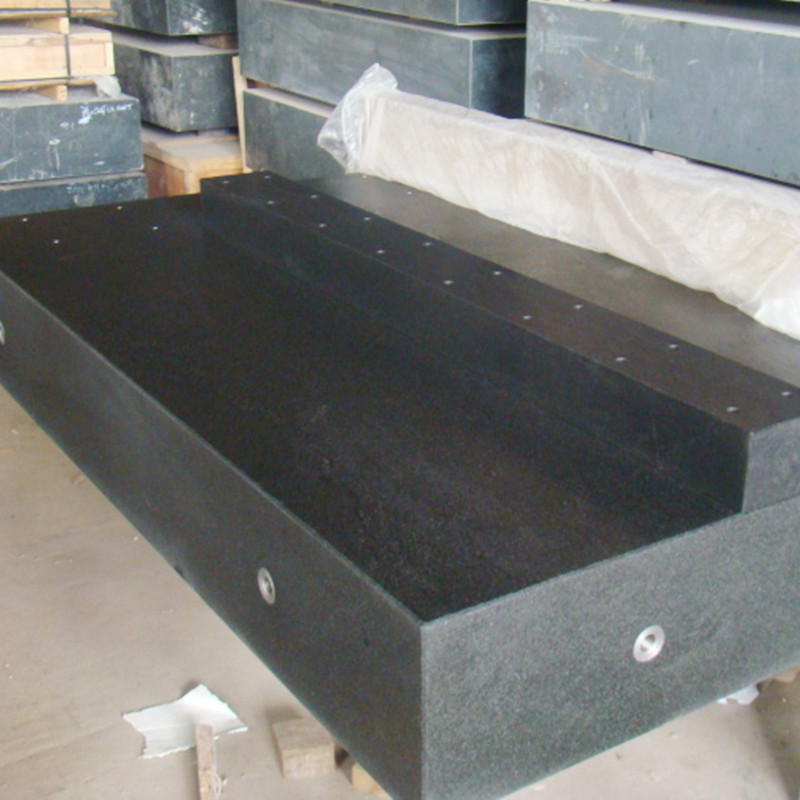

When selecting a welding table, the materials used in construction play a pivotal role. Most welding tables are made from heavy-duty steel, which offers high strength and durability. Stainless steel options are also available, providing resistance to corrosion and easy cleaning. The thickness of the tabletop should be considered, as thicker surfaces provide better stability and can withstand high temperatures without deforming.

In addition to the tabletop material, the frame construction is equally important. A robust, well-welded frame ensures that the table won't flex or wobble during use. Some advanced models come with adjustable legs, allowing users to set the height that best suits their working style.

workbench welding table

Customizable Features

A significant advantage of workbench welding tables is their customizability. Many manufacturers offer tables that can be tailored to meet individual requirements. This may include additional shelving for tools, integrated light fixtures for increased visibility, or modular sections that can be rearranged based on the woodwork requirements.

Further, features such as wheels for mobility or magnetic holds for better positioning can significantly improve workflow and efficiency. Customization not only enhances functionality but also improves the overall user experience by making the welding process more intuitive.

Safety Considerations

Safety should always be a top priority in any welding operation. A quality welding table provides a safe environment by distancing the welder from potential hazards like sparks and spatter. Many models include fire-resistant surfaces and careful design to minimize the risk of injury. Wearing appropriate protective gear, in conjunction with using a well-designed welding table, creates a safer workspace.

Conclusion

In summary, workbench welding tables are much more than mere surfaces for welding; they are essential tools that enhance accuracy, safety, and workflow. With the right materials, construction, and customizable features, a welding table can be an invaluable asset to anyone engaged in welding. By investing time in selecting a suitable welding table, you can significantly improve the quality of your work and enjoy a more efficient and safer welding experience.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS