7月 . 28, 2025 09:45 リストに戻る

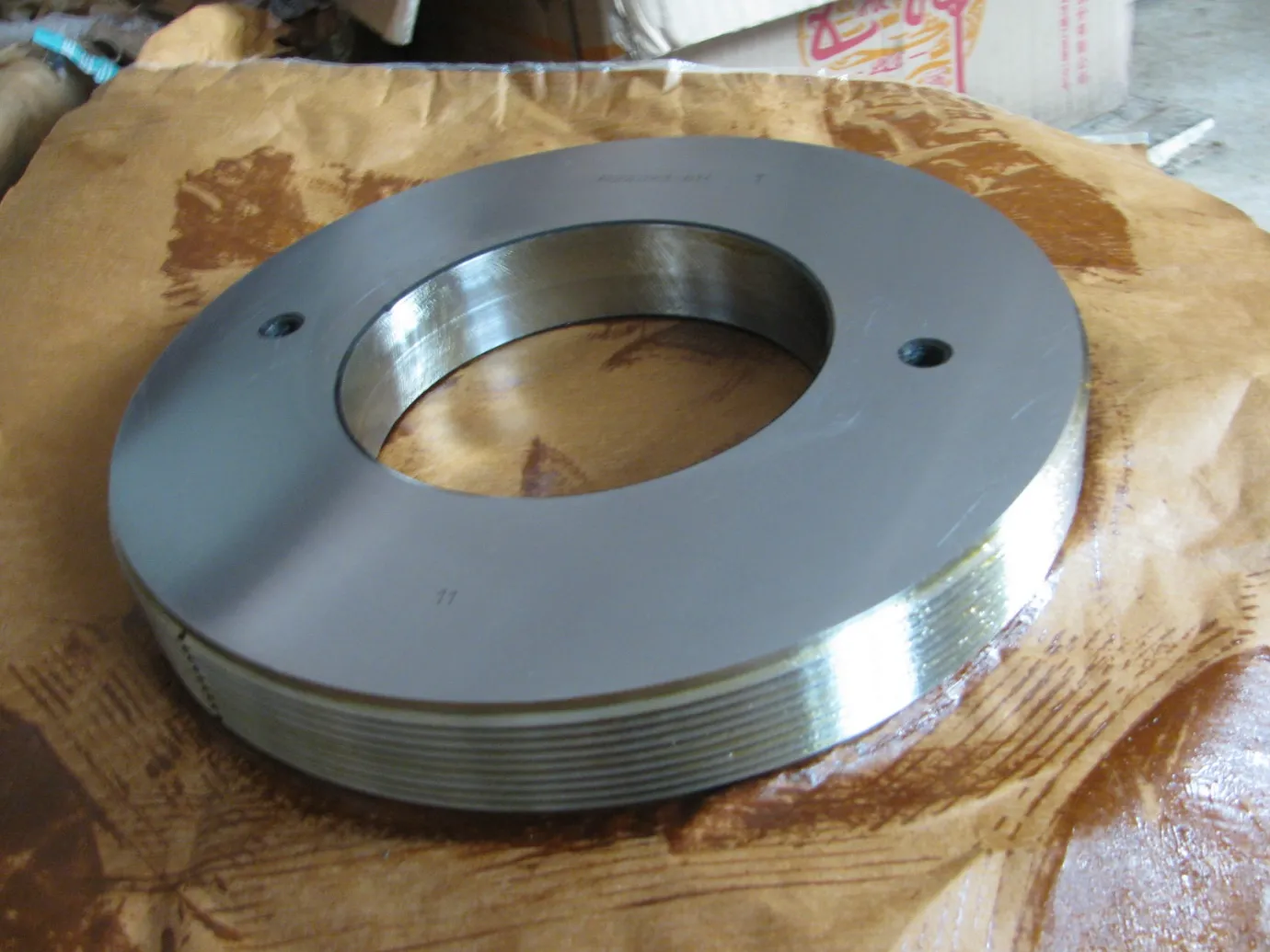

Threaded Ring Gauge Applications

We know precision tools are vital for manufacturing, and threaded ring gauge, thread gauge ring, and ring screw gauge are key. These tools ensure threaded fasteners meet strict standards, with Storaen (Cangzhou) International Trading Co. as a trusted supplier.

Threaded Ring Gauge Applications Across Key Industries

- The threaded ring gauge is crucial in automotive, meticulously checking bolts and studs to guarantee safe, secure connections in engines and chassis, where even minor flaws can risk performance.

- Thread gauge ringaids aerospace, precisely inspecting aircraft fasteners to avoid catastrophic failures that could arise from even tiny thread deviations in high-stress components.

- Ring screw gaugesupports construction, verifying structural bolt threads for bridges and buildings to ensure they can reliably handle extreme loads over decades of use.

- Oil and gas uses threaded ring gaugefor pipe threads, a critical step in preventing costly, dangerous leaks in high-pressure systems that transport valuable resources.

- Electronics relies on miniature thread gauge ringto check tiny connector threads, ensuring seamless assembly of devices where compact, precise components are essential.

Design and Functional Basics of Thread Gauge Ring

- A thread gauge ringis cylindrical with internal threads that exactly match the workpiece’s external threads, a design that ensures strict tolerance compliance in every inspection.

- Threaded ring gaugecomes in Go and No-Go variants; Go checks if threads meet the minimum tolerance, while No-Go ensures they don’t exceed the maximum, leaving no room for ambiguity.

- The design of ring screw gaugeallows quick, efficient inspections in fast-paced manufacturing, maintaining accuracy without slowing down production lines.

- Below is a table on key features:

|

Aspect |

詳細 |

|

Primary Purpose |

A thread gring auge inspects external threads, verifying they conform to specified dimensions and tolerances. |

|

Design |

Cylindrical with internal threads matching the target external thread; available as Go and No-Go variants. |

|

Go Gauge |

Checks if threads meet minimum tolerance—if the male thread fits, it passes the minimum standard. |

|

No-Go Gauge |

Ensures threads don’t exceed maximum tolerance—if the male thread fits, it’s rejected. |

|

Key Use |

Verifies pitch, diameter, and form of external threads on bolts, screws, and fasteners. |

Material and Durability of Ring Screw Gauge

- Ring screw gaugeuses high-grade tool steel and carbide, chosen for their exceptional wear resistance and thermal stability, critical for enduring harsh manufacturing environments.

- Storaen (Cangzhou) International Trading Co. crafts threaded ring gaugewith durability in mind, leveraging Botou’s rich industrial expertise in precision engineering to create long-lasting tools.

- Alongside thread gauge ring, the company supplies cast iron platforms and plug gauges, all built with the same unwavering focus on quality materials and craftsmanship.

- Regular calibration, paired with proper storage, maintains ring screw gaugeaccuracy, extending its lifespan for reliable long-term use in various industrial settings.

Thread Gauge Ring in Quality Control Processes

- Thread gauge ringis central to manufacturing quality control, quickly catching thread deviations early to reduce waste from faulty parts and keep production on track.

- Using threaded ring gaugeensures components fit perfectly, preventing loose connections in machines that could cause costly downtime or pose safety risks to workers.

- Ring screw gaugehelps uphold strict industry standards, enhancing manufacturer reputations for reliability and reducing the high costs associated with rework and product recalls.

- Storaen’s thread gauge ringmeets rigorous international standards, aiding clients in achieving global quality compliance and expanding their market reach with confidence.

Threaded Ring Gauge FAQS

What makes threaded ring gauge essential in manufacturing?

Threaded ring gauge ensures external threads meet precise dimensions and tolerances, a vital role in guaranteeing component compatibility and safety across industries, making it an indispensable tool in manufacturing.

How does thread gauge ring differ from other thread tools?

Thread gauge ring is a specialized cylindrical tool for external threads, unlike tools for internal threads, with unique Go/No-Go features that specifically check tolerance ranges for external fasteners.

Can ring screw gauge be used for all thread types?

Ring screw gauge is versatile but designed for specific thread forms; it works seamlessly with common types like metric and pipe threads, with custom variants available for unique industrial needs.

Why choose Storaen’s threaded ring gauge products?

Storaen (Cangzhou) International Trading Co. offers threaded ring gauge with strict quality checks, durable materials, and deep industry expertise, ensuring reliable performance for diverse manufacturing needs.

How to maintain thread gauge ring accuracy?

To maintain thread gauge ring accuracy, clean it thoroughly after each use, store in dry, protected conditions, and calibrate regularly based on usage frequency, preventing wear from compromising measurements.

Reliable threaded ring gauge, thread gauge ring, and ring screw gauge are vital for precise threaded components. Storaen (Cangzhou) International Trading Co. supplies these tools with a strong commitment to quality. Visit us for all your precision gauge needs.

-

V Blocks for Sale: Types, Uses, and Best Heavy-Duty Frame V OptionsニュースJul.28,2025

-

The Process of Creating Precision Granite Stone BlocksニュースJul.28,2025

-

Key Factors When Selecting Ball Valves for SaleニュースJul.28,2025

-

How Seat Material Affects Performance in Butterfly Valve ApplicationsニュースJul.28,2025

-

Guide to Plain Ring Gages for Industrial Quality ControlニュースJul.28,2025

-

4 Flanged Y Strainer Configurations for Heavy-Duty SystemsニュースJul.28,2025

関連製品