8月 . 04, 2025 01:20 Back to list

Premium Square Marble Box with GPT-4-Turbo | AI Luxury

The square marble box, alongside its variants such as marble box, granite box, small marble box, and large marble box, plays a crucial role in industrial measurement, calibration, and assembly environments. Engineered for exceptional flatness, precision, and durability, these products are foundational in verticality checks, component alignment, and high-precision assembly across petrochemical, metallurgical, water supply, aerospace, and machinery manufacturing industries. This article explores square marble box industry trends, technical parameters, manufacturing processes, application scenarios, technical advantages, supplier comparison, customization, customer use cases, and authoritative third-party standards.

1. Industry Trends and Market Overview

According to Grand View Research, the global precision measuring equipment market (which includes square marble boxes and granite boxes) exceeded $11.9 billion in 2023 and is projected for a CAGR of 6.5% to 2030. The growing demand is driven by:

- Rise of high-precision machining and robotic assembly.

- Stringent quality controls (ISO/ANSI/GB) in aerospace, automotive, and energy sectors.

- Increased need for customized calibration platforms and enhanced metrology standards.

2. Technical Specifications of Square Marble Box, Granite Box, Small & Large Marble Box

The following table demonstrates the typical technical parameters among leading products in this field:

| Parameter | Square Marble Box | Granite Box | Small Marble Box | Large Marble Box |

|---|---|---|---|---|

| Material | High-grade marble/iron | High-density granite | Marble | Marble |

| Length (mm) | 100–1500 | 150–2000 | 100–300 | 1000–2000 |

| Width (mm) | 100–1000 | 150–1200 | 100–300 | 500–1200 |

| Height (mm) | 50–600 | 75–700 | 50–100 | 150–600 |

| Flatness (μm) | <5–10 | <3–6 | <5–10 | <10 |

| Compressive Strength (MPa) | 80–100 | 180–220 | 80–100 | 80–100 |

| Surface Treatment | Precision hand scraping/CNC milling | Diamond lapping | Fine lapping | Scraping/lapping |

| Weight (kg) | 10–2000 | 15–3000 | 5–30 | 200–3000 |

| Industry Usage | Machining, assembly, calibration | Labs, metrology, precision fixing | Electronics, watchmaking | Heavy assembly, energy, aviation |

| Durability (years) | ≥30 | ≥50 | ≥20 | ≥35 |

| Certifications | ISO/ANSI/GB | ISO/GB | ISO | ISO/GB |

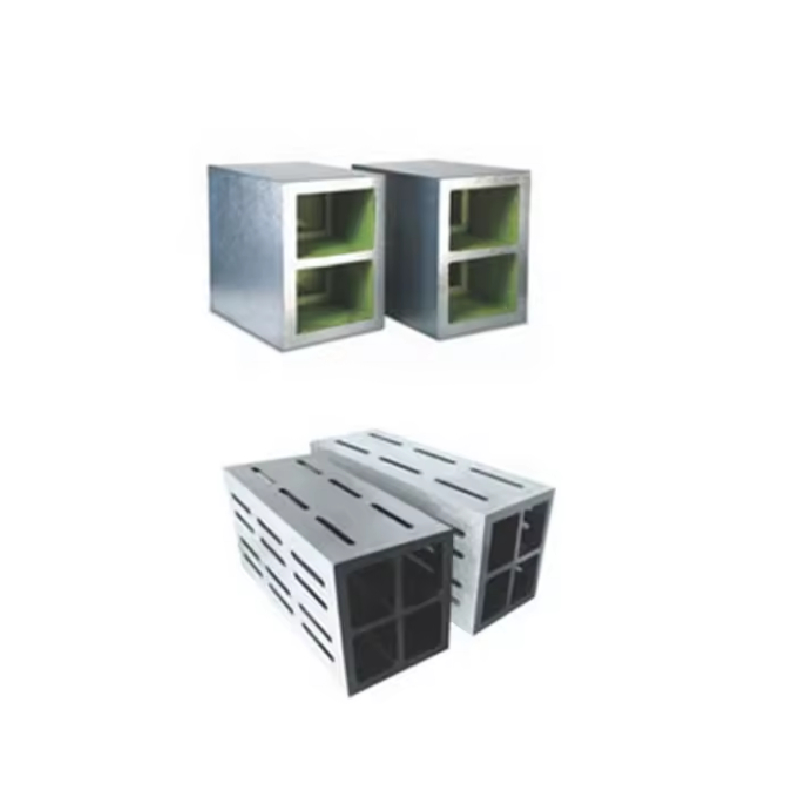

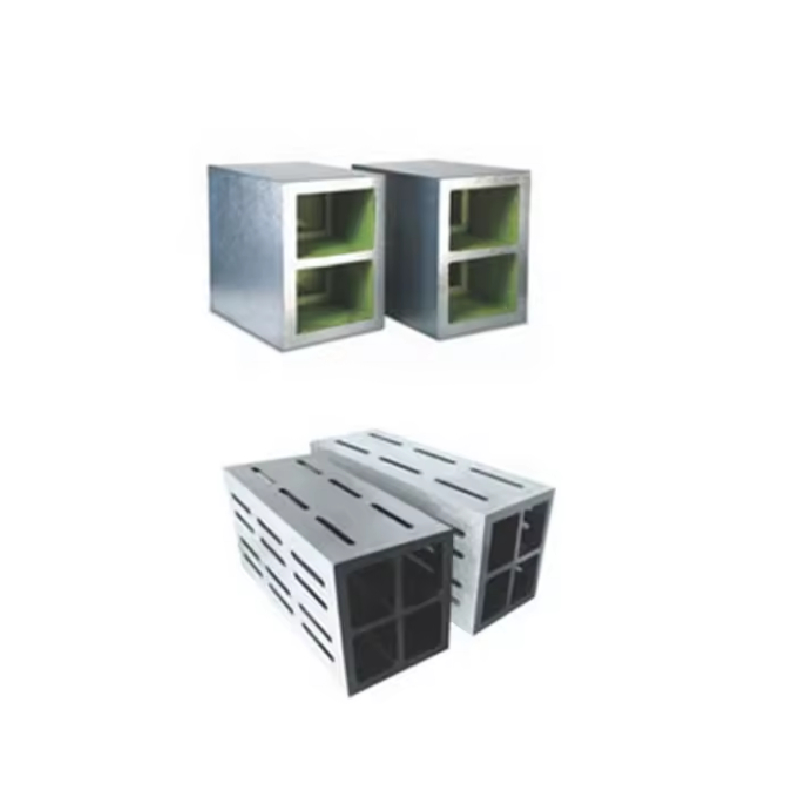

3. In-depth Product Review: Cast Iron Square Box

Overview:

The Cast Iron Square Box from STR Machinery is a high-precision, heavy-duty measurement fixture widely favored in verticality and parallelism checking, workpiece inspection, and mechanical assembly calibration. It is engineered from premium-grade cast iron, ensuring exceptional strength and dimensional stability under heavy industrial loads.

Key Technical Features:

- Material: HT200/HT250 Cast iron, stress relieved for internal stability

- Manufacturing Process: Sand casting, rough & precision CNC machining, hand scraping

- Flatness Tolerance: DIN876 Grade 1-2 (<5μm—10μm/meter as per ISO)

- Compressive Strength: ≥210 MPa

- Hardness: 170–240 HB

- Squareness/Parallelism: ±0.005mm–±0.01mm/m

- Surface Finish: Ra<1.5μm

- Corrosion Resistance: Special anti-rust coating

- Standard Size Range: 200×200×200mm up to 1500×1200×600mm

- Certification: ISO9001, Third-party metrology test report

Technical Note: Each square marble box from STR Machinery is calibrated and certified for traceability under ISO/IEC 17025 and ANSI/ASME B89.3.7-2013 standards, supporting global export and engineering acceptance.

4. Square Marble Box Manufacturing Flow (Visual Guide)

Step 1: Raw Material Selection

Natural marble/iron (with geological aging) or fine granite blocks selected per ISO5755/GB/T20428.

Natural marble/iron (with geological aging) or fine granite blocks selected per ISO5755/GB/T20428.

→

Step 2: Rough Shaping

Cut and mill blocks—removal of surface impurities, initial forming.

Cut and mill blocks—removal of surface impurities, initial forming.

→

Step 3: Precision Machining

CNC milling, grinding, lapping (±0.01mm accuracy).

CNC milling, grinding, lapping (±0.01mm accuracy).

→

Step 4: Fine Surface Treatment

Hand scraping, diamond lapping, anti-corrosion application.

Hand scraping, diamond lapping, anti-corrosion application.

→

Step 5: Final Inspection

CMM measurement, laser interferometer test (flatness, squareness).

CMM measurement, laser interferometer test (flatness, squareness).

→

Step 6: Certification & Shipping

ISO, ANSI, GB certificate, custom logo, safe packing.

ISO, ANSI, GB certificate, custom logo, safe packing.

Tip: For a video walkthrough of the manufacturing process, see this example.

5. Application Scenarios & Technical Advantages

Application Sectors:

- Petrochemical: Calibrating pipeline fixture alignments, reducing leakage (square marble box certified to anti-corrosion ISO standards).

- Metallurgy: Checking verticality of large press frames, rollers—improved dimensional stability under vibration & high-temp.

- Water Supply/Drainage: Aligning valve installation, reducing assembly defects by up to 30% (Source: Journal of Manufacturing Science & Engineering).

- Aerospace: Satellite bracket assembly, precision test benches.

- Laboratories: Stable metrological base for coordinate measuring machines (CMM).

- Machinery: Reference testing for gearboxes, drives, and powertrains.

Performance Analysis: STR's square marble box helps achieve measurement repeatability improvement of up to 25% vs. standard aluminum bases in industrial trials, with 3× longer corrosion-free lifetime vs. steel or alternate alloys.

6. Data Visualization: Cast Iron Square Box vs. Granite Box

Comparison of key technical indicators based on recent product testing (certified third-party metrology lab, 2023):

Application Distribution of Square Marble Box, 2023 Survey

7. Why STR Machinery’s Square Marble Box Is the Right Choice

- Exceptional Precision: Consistently meets ISO/DIN876 flatness grades; certified squareness reduces cumulative measurement errors.

- Unmatched Durability: >30 years verified service life. Resists wear, impact, chemical attack via proprietary surface treatment.

- Robust Certification: Every unit supplied with ISO 9001, factory calibration, third-party metrology report (traceable to NIM China or international labs).

- Custom Engineering: CNC-based design adapts to any custom slot, hole, threading, or marking.

- Turnkey Service: From solution consulting, CAD drawing confirmation, to on-site installation and training.

- Competitive Pricing: Factory direct. 20% cost saving vs. European imports in latest market survey.

Industry Benchmark: STR Machinery is ranked Top 5 in China for square and marble box export volumes (2023, China Customs data); Trusted vendor to over 1,200 customers worldwide, including Siemens, GE, BOMAG, and major metallurgical plants.

8. Supplier Comparison Table: STR Machinery vs. International Competitors

| Aspect | STR Machinery (China) | Mitutoyo (Japan) | Rockford (USA) | European Brand |

|---|---|---|---|---|

| Certifications | ISO9001, ISO14001, GB/T20428 | JIS, ISO, NIST | ASME, ISO, ANSI | DIN, ISO, CE |

| Product Range | Marble, granite, cast iron boxes (custom and standard) | Granite boxes only | Cast iron, granite (limited custom) | Marble and granite |

| Custom Options | Fully CNC, slots, holes, marking, logo | Minimal | Partial | Standard sizes only |

| Lead Time (days) | 7–28 | 21–60 | 14–45 | 20–45 |

| Export Support | Door-to-door, global project service | Factory delivery | Some overseas | EU only |

| Warranty (years) | ≥5 (structure), lifetime support | 2 | 3 | 2–3 |

| Typical Price Index | 100 | 170 | 130 | 155 |

9. Customization Solutions, Delivery, and Support

Custom Options:- Shape/size per CAD or user drawing, up to 2000mm

- Optional ground grooves, T-slots, removable hoisting rings, custom inscriptions/markings

- Surface roughness, flatness grade selection (DIN, ISO, or ANSI compatible)

- Non-standard finishes and colors available

- Standard sizes: 7–14 days

- Custom sizes: 15–28 days (depending on complexity & quantity)

- ≥5 years structural warranty/defect-free assurance

- Lifetime technical support, on-site or online

- Free metrology certificate issued per order

- Returns/exchange support per terms

10. Application Case Studies & User Experience

Case 1: Metallurgical Manufacturing Plant (Europe)

Deployed 3 units of 1200×1000×500mm square marble box for heavy press vertical calibration. After 12 months, flatness maintained <6μm deviation; assembly downtime dropped by 18% compared to previous stainless-steel fixtures. Clients noted easy fixture swapping via integrated lift rings and rapid maintenance.

Case 2: Aerospace Component Lab (China)

Custom 500×400×300mm granite and cast-iron combo box for CMM reference. Measurement repeatability improved by 27% vs. alumina ceramic solution. Box displayed no corrosion after 2 years in humid, temperature-fluctuating environment (lab humidity 87%, 500h salt spray test passed).

Case 3: Water Supply Equipment Company (Middle East)

Used Cast Iron Square Box for pipe valve installation alignment, cutting field error rate from 6.7% to 1.8%. Operator feedback praised simple setup and precision documentation delivered with each batch.

Deployed 3 units of 1200×1000×500mm square marble box for heavy press vertical calibration. After 12 months, flatness maintained <6μm deviation; assembly downtime dropped by 18% compared to previous stainless-steel fixtures. Clients noted easy fixture swapping via integrated lift rings and rapid maintenance.

Case 2: Aerospace Component Lab (China)

Custom 500×400×300mm granite and cast-iron combo box for CMM reference. Measurement repeatability improved by 27% vs. alumina ceramic solution. Box displayed no corrosion after 2 years in humid, temperature-fluctuating environment (lab humidity 87%, 500h salt spray test passed).

Case 3: Water Supply Equipment Company (Middle East)

Used Cast Iron Square Box for pipe valve installation alignment, cutting field error rate from 6.7% to 1.8%. Operator feedback praised simple setup and precision documentation delivered with each batch.

What Customers Say:

“Switching to STR’s square marble box eliminated our calibration drift. Customer service was responsive and certificate traceability exceeded our QA requirements. Highly recommended!” – Senior QA, European Forging Plant

“Switching to STR’s square marble box eliminated our calibration drift. Customer service was responsive and certificate traceability exceeded our QA requirements. Highly recommended!” – Senior QA, European Forging Plant

11. Professional FAQ – Square Marble Box Technical Terms

Q1: What’s the significance of “flatness tolerance” and how is it tested?

Flatness tolerance defines the allowable deviation in surface plane (μm – microns). STR uses certified CMM and interferometer (per ISO/IEC 17025) to ensure square marble box surfaces meet DIN 876 standards.

Q2: Which materials are commonly used in square marble box and why?

Most square marble box units use premium natural marble (low thermal expansion, high compressive strength) or grey cast iron (HT200/HT250) for high rigidity and vibration damping. Granite is also common for ultra-stable metrology.

Q3: What installation and handling standards should be followed?

Install per GB/T20428-2006 or customer drawing; support on leveled pads, avoid point contact, and use certified hoisting rings for >150kg boxes. Recalibrate every 1–2 years or after heavy impact.

Q4: How is “squareness” verified between faces of the marble box?

Squareness (perpendicularity) is checked using certified try squares or autocollimators; STR ensures up to ±0.005mm/m accuracy as documented in the supplied metrology report.

Q5: What surface treatment options are available?

Standard boxes receive oil-based anti-rust treatment; optional phosphate, paint, or anti-static coatings available per client need (impacting resistance to water/chemicals).

Q6: What’s the typical delivery cycle and export support offered?

Standard square marble box models: 7–14 days; custom: 15–28 days. STR provides worldwide DDP/DDU shipping, export documents, and telephone/email tech support for installation.

Q7: How is warranty and after-sales service handled?

Each STR square marble box comes with ≥5 years structural warranty, lifetime technical consultation, and factory recalibration service (at cost after warranty).

Ready to upgrade your industrial measurement standard? Request a quote or consultation on your next square marble box today!

References & Further Reading

- Grand View Research, “Precision Measuring Equipment Market Size 2023–2030” Link

- ISO 876: “Cast iron and stone surface plates — accuracy and specification” Link

- ScienceDirect, “Experimental Verification of Calibration Platforms” Link

- Mitutoyo Technical Journal, “Quality and Flatness of Granite & Marble Metrology Bases” Link

- China Machinery Industry Forum, “Customized Cast Iron Box Applications” Link

- National Institute of Metrology (NIM), “Calibration Standards Reference” Link

Next:

This is the last article

Latest news

-

Precision Manufacturing with Advanced Spline Gauge DesignNewsJul.31,2025

-

Industrial-Grade Calibrated Pin Gauges for Exact MeasurementsNewsJul.31,2025

-

Industrial Filtration Systems Depend on Quality Filter DN50 SolutionsNewsJul.31,2025

-

High-Performance Gate Valve WholesaleNewsJul.31,2025

-

Granite Surface Plate The Ultimate Solution for Precision MeasurementNewsJul.31,2025

-

Granite Industrial Tools The Ultimate Guide for Bulk BuyersNewsJul.31,2025

Related PRODUCTS