Oct . 21, 2024 11:38 Back to list

spline gauge

Understanding Spline Gauges A Comprehensive Overview

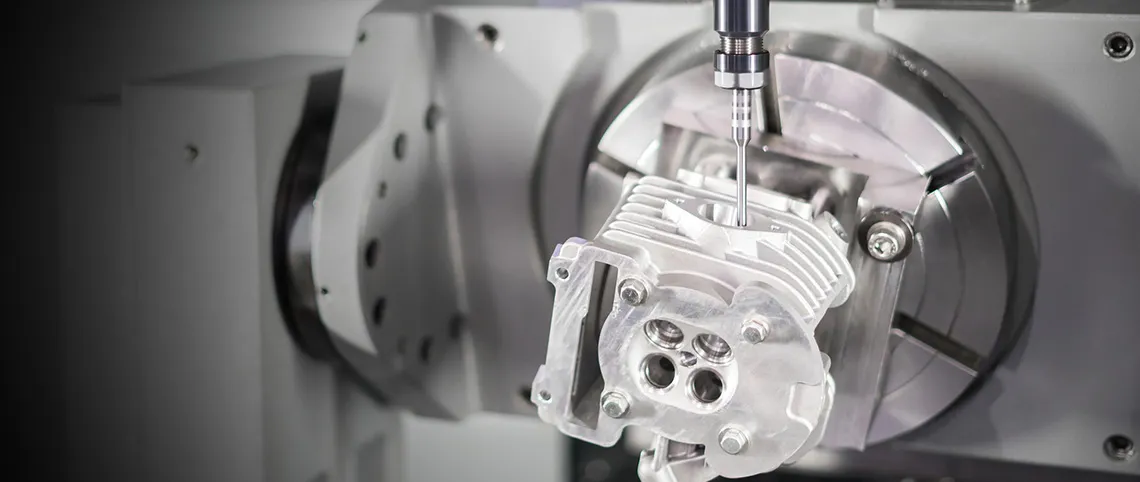

Spline gauges are precision measurement tools widely used in manufacturing and engineering industries. They play a crucial role in ensuring the accurate production of components that require specific spline profiles. But what exactly are spline gauges, and why are they so important?

What are Spline Gauges?

Spline gauges are specialized measuring instruments designed to check the conformity of spline profiles. Splines are linear ridges or teeth on a shaft or inside a hole that perform a crucial function in transmitting torque between two rotating parts. Their precise geometry is vital for ensuring proper engagement, efficient power transmission, and longevity of components such as gears, couplings, and drive shafts.

A spline gauge typically consists of a series of slots or notches that correspond to specific spline dimensions. Each slot is shaped to match a particular spline profile, allowing machinists and quality control inspectors to verify whether a spline meets the required specifications. They often come in various sizes and configurations, tailored for different industries and applications.

The Importance of Precision

Precision is a cornerstone of manufacturing, especially in industries such as automotive, aerospace, and machinery production. The slightest deviation in spline dimensions can lead to problems such as excessive wear, slippage, and even mechanical failure. This is where spline gauges become indispensable.

spline gauge

Using a spline gauge ensures that the manufacturing process maintains high standards of precision. By regularly checking the profiles of splines, manufacturers can identify issues early in production, reducing waste and preventing defects. This proactive approach not only saves resources but also enhances overall product reliability.

Types of Spline Gauges

There are various types of spline gauges, each designed for specific applications. The most common types include

1. Straight Spline Gauges Used for checking straight splines, typically found in shafts and couplings. 2. Internal Spline Gauges Designed to measure internal splines, assuring that the interior profile of a component is within tolerance. 3. External Spline Gauges Used to check external splines, ensuring the exterior teeth of a spline are properly shaped and dimensioned. 4. Go/No-Go Gauges These gauges determine whether a spline fits within two specific tolerances, thus providing a simple pass/fail assessment.

Conclusion

In conclusion, spline gauges are essential tools in precision manufacturing, ensuring that splines meet exact specifications. Their role in quality control cannot be overstated, as they help prevent costly mistakes and maintain production efficiency. As industries continue to evolve and demand higher standards, the importance of accurate measurement tools like spline gauges will only grow. For manufacturers seeking to maintain competitive advantage, investing in reliable spline gauges is a step towards achieving excellence in product quality and performance. In an industry where reliability and precision are paramount, spline gauges serve as the guardian of quality, ensuring that every component fits and functions as intended.

-

Wear Resistance Strategies for Trapezoidal ThreadsNewsJun.26,2025

-

Selecting Thread Gauge Types for Aerospace Component InspectionsNewsJun.26,2025

-

Ring Gauge Influence on Cigar Aging Potential and Storage SolutionsNewsJun.26,2025

-

Pin Gauge Training Programs for Enhanced Dimensional Inspection SkillsNewsJun.26,2025

-

Custom Spline Ring Gauge Design for Unique Engineering NeedsNewsJun.26,2025

-

Cost-Effective Alternatives to Custom Threaded Ring GaugesNewsJun.26,2025

Related PRODUCTS