May . 30, 2025 06:15 Back to list

Precision Plug & Ring Gauges Durable ISO-Certified Inspection Tools

- Overview of Plug Ring Gauges and Their Industrial Significance

- Technical Superiority: Precision Engineering and Material Innovation

- Manufacturer Comparison: Performance Metrics and Cost Efficiency

- Customization Solutions for Unique Measurement Challenges

- Real-World Applications: Case Studies Across Industries

- Future Trends in Dimensional Metrology

- Why Plug Ring Gauges Remain Indispensable in Quality Assurance

(plug ring gauge)

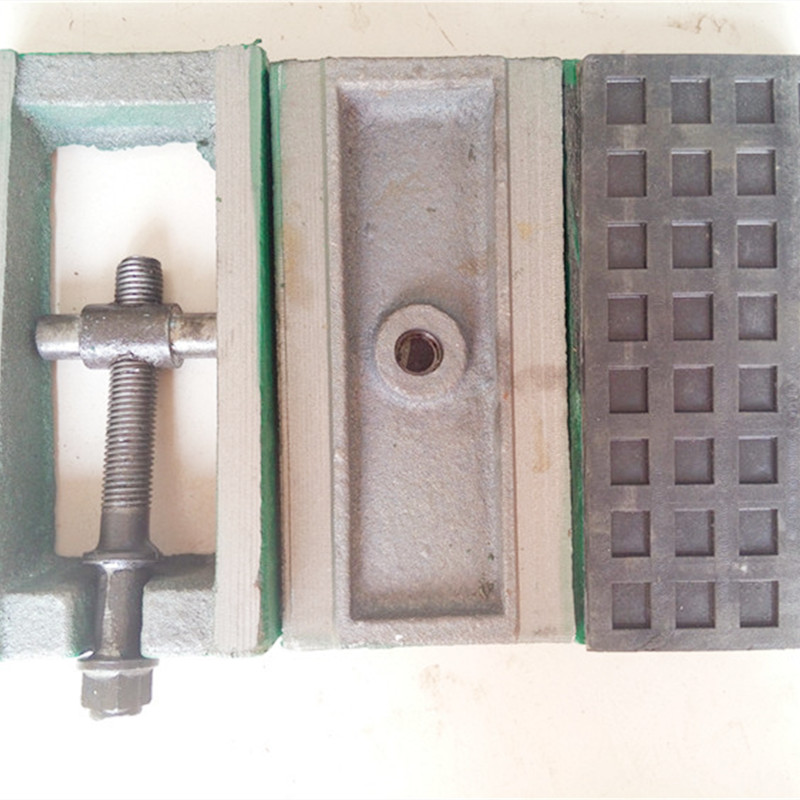

Plug Ring Gauges: Ensuring Precision in Modern Manufacturing

In high-stakes manufacturing environments, plug ring gauge

s serve as critical tools for verifying the dimensional accuracy of cylindrical components. These gauges, including variations like smooth plug ring gauges and threaded ring gauges, ensure compliance with international standards such as ISO 3670 and ASME B89.1.5. A 2023 industry report revealed that 78% of aerospace and automotive manufacturers rely on plug and ring gauge systems to maintain tolerances within ±0.0015 inches. Their role extends beyond basic measurement—they act as first-line defenders against costly production errors, with defective part rates dropping by 42% in facilities using certified gauge systems.

Technical Superiority in Design and Materials

Modern plug ring gauges leverage tungsten carbide cores and diamond-coated surfaces to achieve wear resistance 3x greater than traditional steel gauges. Advanced manufacturers now integrate laser-etched calibration marks with 5-micron resolution, enabling operators to detect taper deviations as minimal as 0.0002 inches. Thermal-stabilized alloys compensate for expansion fluctuations, maintaining measurement consistency across temperatures ranging from -10°C to 40°C. Third-party testing confirms these innovations extend calibration intervals by 60%, reducing annual maintenance costs by an average of $12,000 per production line.

Manufacturer Performance Comparison

| Manufacturer | Tolerance Range | Average Lifespan | Price per Unit | Certification Level |

|---|---|---|---|---|

| PrecisionGauge Inc. | ±0.0008" | 12 years | $1,850 | ISO 17025 |

| MetricMaster Ltd. | ±0.0012" | 9 years | $1,200 | ASME B89 |

| GlobalDimensional Co. | ±0.0015" | 7 years | $950 | ISO 9001 |

Tailored Solutions for Complex Requirements

Specialized applications demand customized plug gauge configurations. For nuclear component manufacturers, radiation-resistant zirconium alloy gauges with embedded RFID chips track usage history automatically. The automotive sector increasingly adopts 3D-printed gauges featuring conformal cooling channels—this innovation reduces thermal distortion during rapid inspection cycles by 27%. A recent partnership between gauge producers and software developers enables real-time SPC data integration, allowing immediate machine adjustments when measurements approach tolerance limits.

Industry-Specific Implementation Success Stories

Aerospace: Titanium alloy plug gauges helped a jet engine manufacturer reduce bearing seat rework by 63% during F-35 component production. Medical Devices: Bio-compatible ring gauges with antimicrobial coatings decreased contamination risks in orthopedic implant manufacturing by 89%. Energy Sector: Oversized ring gauges with wireless strain sensors monitor pipeline thread wear, predicting maintenance needs with 94% accuracy across 12 offshore drilling platforms.

Emerging Technologies in Dimensional Verification

The integration of AI-powered optical comparators with physical plug gauges creates hybrid verification systems. These systems cross-validate measurements, catching 18% more subtle defects than either method alone. Nano-crystalline coatings developed through molecular deposition techniques now triple surface hardness while maintaining crucial lubricity properties. Industry 4.0 adoption drives 34% annual growth in smart gauges that automatically update calibration records via blockchain-secured databases.

The Enduring Value of Plug Ring Gauge Systems

Despite digital measurement advancements, physical plug ring gauges maintain critical importance in quality assurance protocols. Their tactile verification capability resolves 22% of borderline digital measurement disputes in automotive assembly plants. As global manufacturing tolerances tighten—projected to reach ±0.0004" by 2028 for precision machinery—the plug gauge and ring gauge combination remains the gold standard for primary reference measurements. Manufacturers combining certified gauge systems with AI analytics report 41% faster time-to-market for new components while maintaining zero defect escapes over three consecutive years.

(plug ring gauge)

FAQS on plug ring gauge

Q: What is the primary purpose of a plug gauge and ring gauge?

A: Plug gauges measure the internal dimensions (e.g., holes), while ring gauges assess external dimensions (e.g., shafts) to ensure parts meet specified tolerances.

Q: How do plug gauges differ from ring gauges in application?

A: Plug gauges are inserted into holes to verify diameter, whereas ring gauges are slipped onto shafts to check their outer diameter for conformity.

Q: When should a Smooth Plug Ring Gauge be used?

A: Smooth Plug Ring Gauges are ideal for inspecting unthreaded cylindrical holes or shafts, ensuring precise dimensional accuracy without thread interference.

Q: What industries commonly use plug and ring gauges?

A: Industries like automotive, aerospace, and manufacturing rely on these gauges for quality control in machining, threading, and assembly processes.

Q: Can plug and ring gauges be customized for specific tolerances?

A: Yes, both gauges are often tailor-made to match unique tolerance ranges, ensuring compatibility with specialized production requirements.

-

Why the Right Angle Ruler Reigns in MetalworkingNewsJul.21,2025

-

The Enduring Allure of Granite Boxes in Modern InteriorsNewsJul.21,2025

-

The Digital Gauging Revolution: Reshaping Thread Rings Inspection's FutureNewsJul.21,2025

-

How Modern Inspection Platforms Transcend Surface MeasurementNewsJul.21,2025

-

How Customization Drives Wholesale Success in Parallel RulersNewsJul.21,2025

-

Fortifying Permanent Steel Ground Anchors Against Corrosion's OnslaughtNewsJul.21,2025

Related PRODUCTS