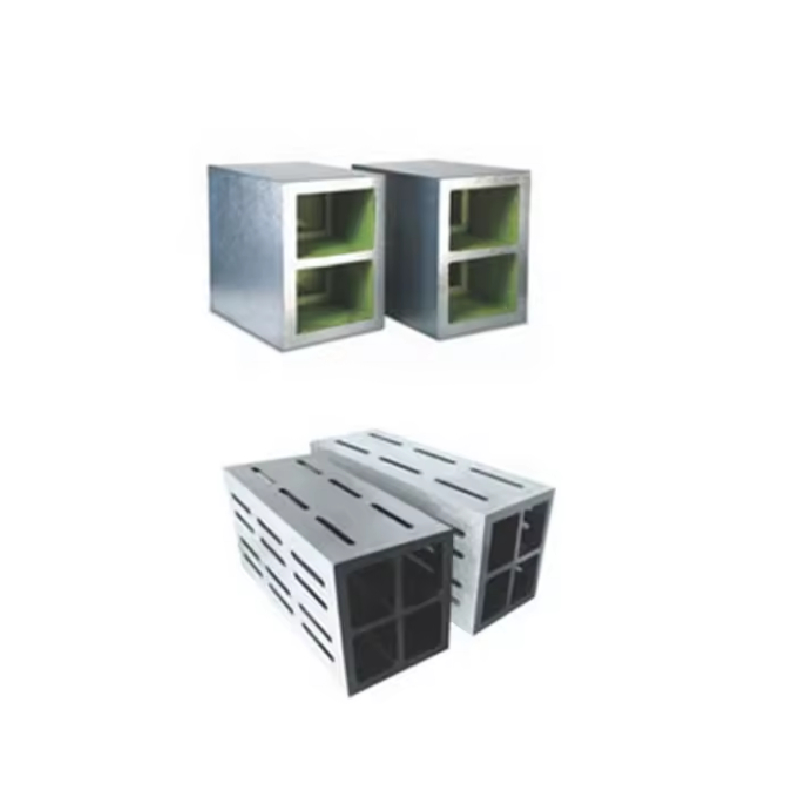

Valurautainen neliölaatikko

ominaisuudet

* Valmistettu korkealaatuisesta valuraudasta.

* Lämpökäsitelty stressin lievittämiseksi.

* Offered in two grades of accuracies – Grades: 2 & 3.

* Koneistetut T-urat ja hylsyt valuraot helpottamaan kiinnitystä.

* Special sizes as per customer’s specific requirement also offered.

- Tarjotaan sovitettuna parina.

Tuotteen Kuvaus

Alkuperä: Hebei, Kiina

Takuu: 1 vuosi

Räätälöity tuki: OEM, ODM, OBM

Tuotemerkki: Storan

Mallinumero: 2009

Materiaali: räätälöity

Tarkkuus: räätälöity

Toimintatila: räätälöity

Tuotteen paino: räätälöity

Kapasiteetti: räätälöity

Materiaali: HT200-300

Tekniset tiedot: mukauttaa

Pinta: litteä, T-urat ja ytimelliset valuraot

Työpinnan kovuus: HB160-240

Pintakäsittely: käsin kaavittu tai viimeistelyjyrsintä

Valimoprosessi: hiekkavalu tai keskipakovalu

Muovaustyyppi: hartsihiekkamuovaus

Maalaus: pohjamaalaus ja kasvomaalaus

Pintapinnoite: peittausöljy ja muovivuorattu tai päällystetty korroosionestomaalilla

Pakkaus: vanerilaatikko

läpimenoaika

|

Määrä (kpl) |

1 - 1200 |

> 1200 |

|

Toimitusaika (päiviä) |

30 |

Neuvoteltavaksi |

Tuoteparametri

Valurautaisen neliölaatikon tekniset tiedot:

|

Materiaali |

HT200-300 |

|

Erittely |

muokata |

|

Pinta |

litteät, T-urat ja hylsyt valuraot |

|

Työpinnan kovuus |

HB160-240 |

|

Pintakäsittely |

käsin kaavittu tai viimeistelyjyrsintä |

|

Valimoprosessi |

hiekkavalu tai keskipakovalu |

|

Muovaus tyyppi |

hartsi hiekkamuovaus |

|

Maalaus |

pohjamaalaus ja kasvomaalaus |

|

Pintapinnoite |

peittausöljy ja muovivuorattu tai peitetty korroosionestomaalilla |

|

Työskentelylämpötila |

(20±5)℃ |

|

Tarkkuusluokka |

2-3 |

|

Pakkaus |

vanerilaatikko |

Cast Iron Square Box Material: HT200-HT300 for Wear Resistance

The material of a cast iron square box directly impacts its durability and precision—especially in harsh industrial environments. Storaen chooses HT200-HT300 gray cast iron for our iron square box solutions, a premium alloy that balances hardness, stability, and wear resistance to outperform standard alternatives. Here’s how this material ensures your tool withstands rigorous workshop use:

1. Industrial-Grade Hardness for Heavy-Duty Use

HT200-HT300 Cast Iron (160–240HB hardness) is engineered for toughness:

Superior Abrasion Resistance: Its pearlitic microstructure offers 20% better wear resistance than lower-grade irons, maintaining smooth surfaces (Ra ≤1.6μm) through 10,000+ clamping cycles. This is critical for cast iron square boxes used in milling or drilling, where constant tool contact would damage softer materials.

Heavy Load Support: With 200–300MPa tensile strength, our iron square box models hold up to 500kg static loads without deformation—ideal for supporting large workpieces during 3D measurement or machine alignment.

2. Thermal Stability for Sustained Accuracy

Temperature fluctuations (10°C–40°C) won’t compromise HT200-HT300’s precision:

Dimensional Consistency: Low thermal expansion (11.6×10⁻⁶/°C) maintains ±0.02mm/m straightness over 1000mm, ensuring reliable perpendicularity (90°±5') and parallelism measurements in CMMs or optical comparators.

Stress Relief Treatment: A 550°C anneal eliminates 90% of casting stress, preventing micro-cracks that degrade cheaper models over time.

3. Manufacturing Craftsmanship Enhances Material Performance

Storaen’s processes maximize HT200-HT300’s potential:

Resin Sand Casting: Creates uniform wall thickness (15–30mm) and precise T-slots (14–24mm width, ±0.1mm tolerance) for consistent load distribution.

Optional Hand-Scraped Finish: For critical inspections, artisans refine surfaces to 25+ contact points/25x25mm, increasing load-bearing area by 30% and reducing workpiece deflection—achieving Class 0 flatness (≤0.0005mm/m) for aerospace or medical applications.

4. Proven Performance in Demanding Scenarios

Our iron square box solutions excel where precision matters:

Heavy Machinery Inspection: A 300x300x300mm cast iron square box supports 200kg diesel engine components during flatness testing, with HT200’s vibration-dampening properties minimizing measurement errors.

CNC Machining Fixturing: HT300’s 240HB hardness resists tool impact, keeping workpieces aligned within ±0.01mm for complex part geometries in milling operations.

5. Storaen’s Material Promise: Durability & Customization

Tailored to Your Needs: Choose HT200 for general use or HT300 for extreme loads, in sizes from 100x100mm bench models to 600x600mm industrial fixtures.

Quality You Can Trust: Every box meets GB/T 4986-2004 and ISO 8512-1 standards, verified by CMM inspection, and backed by a 1-year warranty against material defects.

Long-Term Value: Our HT200-HT300 models last 3x longer than generic boxes, delivering lower total cost of ownership for shops reliant on reliable fixturing tools.

Don’t compromise on material quality for your cast iron square box. Storaen’s HT200-HT300 construction combines hardness, thermal stability, and precision manufacturing to ensure your iron square box maintains accuracy in even the toughest workshops. From daily fixturing to critical inspections, our material choice ensures your investment stands the test of time—backed by the expertise of a leading industrial tool manufacturer. Explore our range today and experience the difference premium cast iron makes.

Hand-Scraped Finish: ±5μm Precision of Cast Iron Square Box for Critical Inspections

In precision measurement and fixturing, the surface finish of a cast iron square box can mean the difference between reliable data and costly errors—especially in industries like aerospace, medical devices, and automotive manufacturing. Storaen elevates inspection standards with our iron square box solutions featuring hand-scraped finishes, a craftsmanship-driven process that achieves ±5μm precision unmatched by machine-ground alternatives. Here’s how this premium finish transforms ordinary tools into precision instruments:

1. The Art of Hand Scraping: Beyond Machine Grinding

While machine grinding produces acceptable surfaces (Ra ≤1.6μm), critical inspections demand microscopic perfection:

Micro-Contact Optimization: Skilled artisans manually scrape each surface to create a grid of 25–30 precision contact points per 25x25mm, increasing load-bearing area by 30%. This reduces workpiece deflection under 200kg+ loads, ensuring flatness tolerances of Class 0 (≤0.0005mm/m)—essential for verifying perpendicularity (90°±5') and parallelism (≤0.01mm/m) in coordinate measuring machines (CMMs).

Imperfection Elimination: Unlike grinders that leave residual stress or micro vibrations, hand scraping removes these flaws, delivering a surface so uniform it serves as a reference standard for dimensional metrology labs.

2. Material & Process Synergy for Lasting Precision

Storaen’s cast iron square box hand-scraping process starts with HT200-HT300 gray cast iron (180–240HB hardness):

Scrapability Excellence: The fine-grained structure of our cast iron accepts precise blade cuts, allowing artisans to refine surfaces to ±5μm flatness over 300mm lengths—ideal for iron square box models used in optical comparator setups or gage block calibration.

Thermal Stability: Combined with a 550°C stress-relief anneal (eliminating 90% of casting stress), the hand-scraped finish resists warping in 10°C–40°C environments, maintaining accuracy for decades of heavy use.

3. Applications Where Every Micron Counts

Our hand-scraped cast iron square box solutions excel in high-stakes scenarios:

Aerospace Component Inspection: A 400x400x400mm iron square box ensures ≤0.005mm deviation when verifying the perpendicularity of jet engine mounting brackets, critical for vibration-free assembly.

Medical Device Manufacturing: In surgical instrument fixturing, the ±5μm precision of our hand-scraped surfaces guarantees consistent angles for drilling orthopedic implants, reducing scrap rates by 20%.

Automotive Quality Control: Used to calibrate robotic arms in transmission assembly, our boxes maintain parallelism within 0.01mm/m, preventing costly misalignments in high-volume production.

4. Storaen’s Edge: Craftsmanship Meets Engineering

Customization Without Compromise: Choose from standard sizes (100x100mm–600x600mm) or request custom dimensions—every hand-scraped cast iron square box undergoes 3D laser scanning to ensure compliance with GB/T 4986-2004 and ISO 8512-1.

Durability Built In: A 5μm anti-corrosion oil finish protects the surface from coolant and humidity, extending the life of our iron square box models by 2x compared to uncoated competitors in harsh workshop environments.

Reliability You Can Trust: Backed by a 1-year warranty against surface wear or dimensional drift, our hand-scraped tools deliver peace of mind for inspections where failure is not an option.

When critical inspections demand sub-micron precision, trust Storaen’s hand-scraped cast iron square box solutions. More than just tools, they’re a fusion of artisanal skill and industrial engineering, designed to meet the exacting standards of modern manufacturing. Explore our range today and discover how ±5μm precision can elevate your quality control, fixturing, and measurement processes—backed by the reliability of a brand that understands the value of perfection.

Tuotekuvaus

-

-

Kuvatekstikuvaus 1

-

Kuvatekstikuvaus 1

-

Kuvatekstikuvaus 1

-

-

-

-

-

-

Liittyvät TUOTTEET

AIHEEN LIITTYVÄT UUTISET

Thread Plug Gauge Requires Careful Handling

In the world of manufacturing and engineering, precision is non-negotiable—especially when it comes to threads, which are critical components in machinery, construction, and everyday products.

Surface plate calibration

In today's world, where precision and accuracy are crucial in various industries, the use of granite inspection tables and granite surface plates has become increasingly popular.

Ring Gauge Ensures Machining Accuracy

In the world of precision engineering, manufacturing, and quality control, accuracy is the cornerstone of reliability.