Ots . 14, 2025 02:26 Back to list

check valve assy

In the realm of plumbing and industrial applications, the importance of a well-functioning check valve cannot be overstated. One of the most innovative and efficient types in this category is the disco check valve. Professionals seeking to optimize flow control while maintaining a robust, reliable system often turn to this solution.

The installation of disco check valves is straightforward, and their maintenance is remarkably easy compared to other valve types. Regular inspections and basic cleaning of the disk and sealing areas can prevent major issues, ensuring that the system remains efficient over long periods. Employing a routine maintenance schedule can further enhance system reliability and trustworthiness. From a cost-effectiveness perspective, these valves offer significant savings. Their durability and minimal maintenance needs reduce operational costs and potential losses from system downtime. Moreover, their efficiency in preventing backflow and contamination can prevent expensive damage to adjacent equipment and pipelines. Disco check valves also contribute to environmental sustainability. By ensuring proper flow control and preventing contamination, they help industries comply with environmental regulations and reduce their ecological footprint. This aspect not only aids in fostering an environmentally conscious operation but also strengthens the trust and credibility of businesses committed to sustainable practices. In the competitive landscape of industrial components, the expertise and authority of suppliers play crucial roles. Partnering with a trusted manufacturer or distributor ensures access to high-quality disco check valves, comprehensive technical support, and industry insights, empowering businesses to make strategic decisions in their fluid handling operations. The disco check valve stands as a testament to engineering excellence, combining design ingenuity with practical application. Its role in facilitating efficient and sustainable fluid management is undeniable, making it an invaluable component across various industries. Whether for seasoned engineers or businesses seeking new solutions, investing in disco check valves is a decision backed by expertise and driven by the promise of long-term reliability and performance.

The installation of disco check valves is straightforward, and their maintenance is remarkably easy compared to other valve types. Regular inspections and basic cleaning of the disk and sealing areas can prevent major issues, ensuring that the system remains efficient over long periods. Employing a routine maintenance schedule can further enhance system reliability and trustworthiness. From a cost-effectiveness perspective, these valves offer significant savings. Their durability and minimal maintenance needs reduce operational costs and potential losses from system downtime. Moreover, their efficiency in preventing backflow and contamination can prevent expensive damage to adjacent equipment and pipelines. Disco check valves also contribute to environmental sustainability. By ensuring proper flow control and preventing contamination, they help industries comply with environmental regulations and reduce their ecological footprint. This aspect not only aids in fostering an environmentally conscious operation but also strengthens the trust and credibility of businesses committed to sustainable practices. In the competitive landscape of industrial components, the expertise and authority of suppliers play crucial roles. Partnering with a trusted manufacturer or distributor ensures access to high-quality disco check valves, comprehensive technical support, and industry insights, empowering businesses to make strategic decisions in their fluid handling operations. The disco check valve stands as a testament to engineering excellence, combining design ingenuity with practical application. Its role in facilitating efficient and sustainable fluid management is undeniable, making it an invaluable component across various industries. Whether for seasoned engineers or businesses seeking new solutions, investing in disco check valves is a decision backed by expertise and driven by the promise of long-term reliability and performance.

Next:

Latest news

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

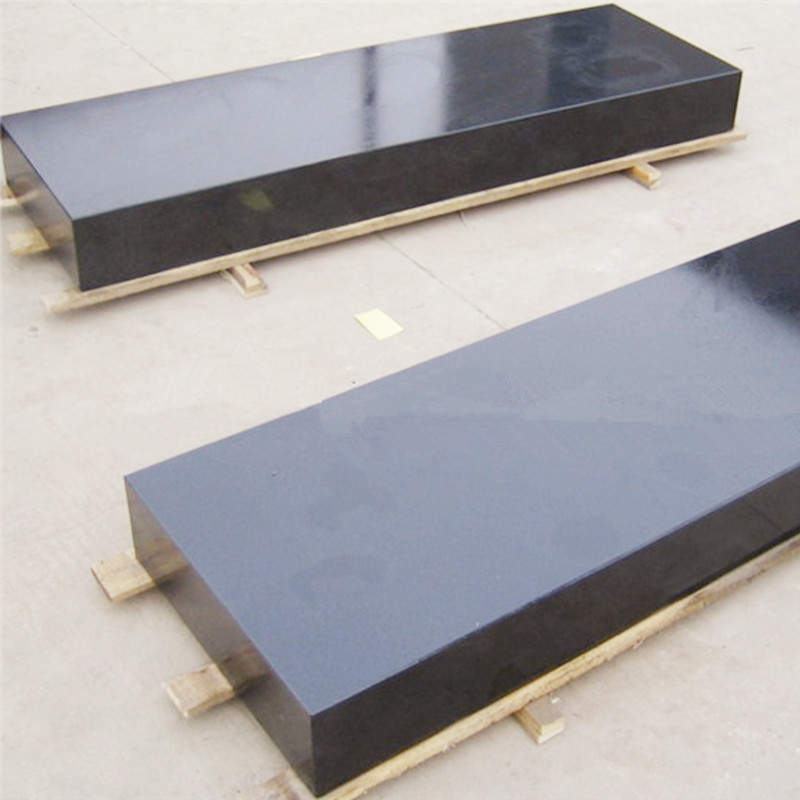

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS