Jul . 04, 2025 09:32 volver a la lista

Magnetic Vee Block Materials

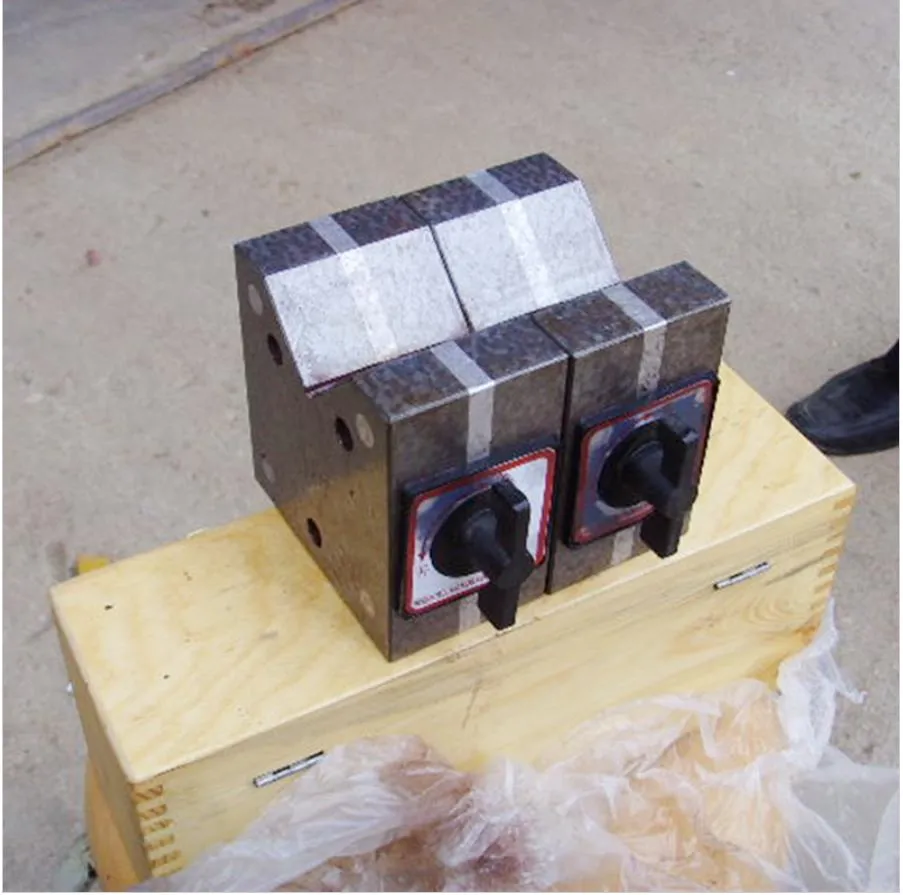

Precision workholding requires reliable fixtures like magnetic vee block products, available in standard sizes including magnetic v block 4 inch and magnetic v block 6 inch configurations. These essential tools combine magnetic securing power with precision-ground surfaces for optimal workpiece positioning. Let's examine their key material characteristics and applications.

Material Composition of Magnetic Vee Block

- High-grade ferromagnetic alloys form the core of magnetic v block 4 inch productos

• Precision-ground tool steel surfaces ensure magnetic vee block accuracy

• Hardened wear plates protect magnetic v block 6 inch contact surfaces

• Corrosion-resistant coatings on premium magnetic vee block models

• Temperature-stable materials prevent magnetic v block 4 inch deformation

|

A |

B |

H |

E |

Working Magnetic Force (kg) |

|

60 |

60 |

60 |

30 |

40kg |

|

100 |

60 |

100 |

60 |

50kg |

|

150 |

60 |

120 |

90 |

60kg |

Dimensional Specifications for Magnetic V Block 4 Inch

- Standard 4" length magnetic vee blockfor smaller workpieces

• 90° V-angle design in magnetic v block 4 inchfor universal applications

• Ground flatness within 0.0005" for precision magnetic vee block models

• Magnetic strength up to 100 lbs for secure magnetic v block 4 inch holding

• Weight-optimized magnetic vee block design for easy handling

Performance Features of Magnetic V Block 6 Inch

- Extended 6" length magnetic vee blockfor larger diameter workpieces

• Enhanced magnetic circuits in magnetic v block 6 inchfor stronger holding

• Multi-directional workpiece access with magnetic vee block design

• Precision-ground surfaces on magnetic v block 6 inch maintain ±0.001" accuracy

• Through-hole options available in some magnetic vee block configurations

Industrial Applications for Magnetic Vee Block

- Cylindrical workpiece fixturing with magnetic v block 4 inchprecisión

• Grinding machine operations using magnetic v block 6 inchstability

• EDM and wire cutting setups with magnetic vee block security

• Inspection and measurement with magnetic v block 4 inch repeatability

• Machining center applications requiring magnetic v block 6 inch rigidity

Maintenance Guidelines for Bloque magnético en V

- Regular cleaning of magnetic vee blockcontact surfaces

• Periodic demagnetization of magnetic v block 4 inchtools

• Proper storage to protect magnetic v block 6 inch precision surfaces

• Inspection for wear on magnetic vee block magnetic faces

• Lubrication of moving parts in adjustable magnetic v block models

Magnetic Vee Block FAQS

Q: What makes a magnetic vee block suitable for holding cylindrical workpieces?

A: A magnetic vee block has a V - shaped groove that conforms to the round profile of cylindrical workpieces. Its magnetic force provides secure, non - marring holding, keeping the workpiece stable during machining, inspection, or grinding. The V - shape centers the workpiece, ensuring accurate alignment, which is crucial for tasks like centering a shaft for turning or checking roundness.

Q: How does a magnetic v block 4 inch differ from a 6 - inch one in practical use?

A: A magnetic v block 4 inch is more compact, ideal for smaller workpieces or setups with limited space. It can handle shorter or narrower cylindrical items. The magnetic v block 6 inch offers a longer supporting surface, suitable for longer workpieces, distributing magnetic force over a greater length. This helps in stabilizing extended shafts or pipes during operations like large - scale milling or alignment checks.

Q: Can a magnetic vee block be used with non - magnetic workpieces?

A: No, a magnetic vee block relies on magnetic attraction. For non - magnetic workpieces (e.g., made of aluminum, copper, or plastic), auxiliary clamping methods like mechanical clamps or vices need to be used in conjunction. However, the V - shaped groove still helps in centering, but the holding force won’t come from the block’s magnetism.

Q: What maintenance is required for a magnetic v block 6 inch?

A: Keep the magnetic v block 6 inch clean, removing metal chips, dust, or debris that can affect magnetic force or accuracy. Check the magnetic strength regularly—if it weakens, some blocks can be re - magnetized (following manufacturer guidelines). Inspect the V - groove and surface for wear or damage, as nicks can impact workpiece alignment. Store it properly, away from strong magnetic fields that might disrupt its magnetism.

Q: Are there safety concerns when using a magnetic vee block?

A: Yes. When handling, be careful of pinch points if the block is powerful—fingers can get caught between the block and a workpiece. Also, the strong magnetism can affect nearby electronic devices or magnetic storage media (like hard drives). When placing or removing workpieces, do it gently to avoid sudden impacts that could damage the block or workpiece, and always ensure the workpiece is securely held before starting operations.

Welcome to Storaen Machinery,Step into the world of Storaen (Cangzhou) International Trading Co., your trusted partner from Botou, China – a global hub of precision manufacturing. At www.strmachinery.com , we blend decades of expertise with cutting-edge innovation, crafting top-tier cast iron welding platforms, measuring tools, and valves that redefine industrial reliability.

Our roots in Botou’s casting legacy fuel unmatched quality, while a relentless drive for innovation ensures we stay ahead of industry trends. Committed to sustainability and customer success, we don’t just build products – we forge partnerships. Whether you’re engineering the future or perfecting precision, let Storaen’s legacy of excellence power your next project. Welcome to a world where quality meets ambition – let’s build greatness together.

-

Flanged Gate Valve: A Reliable Choice for Industrial and Municipal SystemsNoticiasAug.20,2025

-

Soft Seal Gate Valve: A Modern Solution for Reliable Pipeline ControlNoticiasAug.20,2025

-

Gate Valve Types: Understanding the Options for Your Pipeline SystemsNoticiasAug.20,2025

-

Y Type Strainer: Essential for Clean and Efficient Flow SystemsNoticiasAug.20,2025

-

Cast Iron Y Strainer: Durable Solutions for Demanding ApplicationsNoticiasAug.20,2025

-

Flanged Y Strainer: An Essential Component in Industrial Filtration SystemsNoticiasAug.20,2025

Productos relacionados