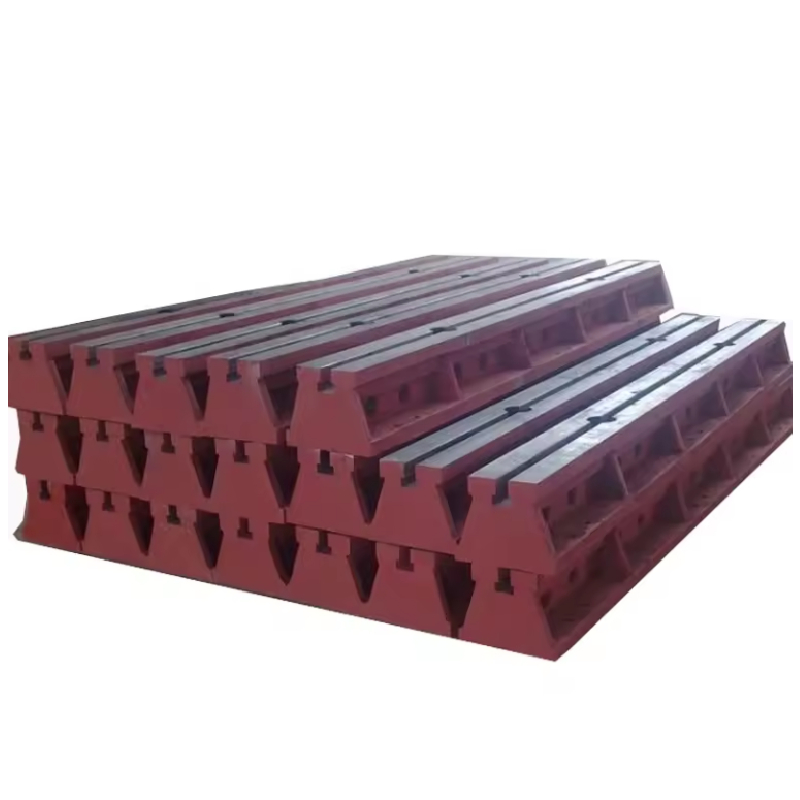

Carril de guía

Descripción del Producto

Lugar de origen: Hebei, China

1 año de garantía

Soporte personalizado: OEM, ODM, OBM

Nombre de la marca: Storan

Número de modelo: 2008

Material:HT200-HT300

Precisión: personalizado

Modo de operación: personalizado

Peso del artículo: personalizado

Capacidad: personalizado

Especificación: 1500-4000 mm de longitud o personalizar

Superficie: ranuras en T

Dureza de la superficie de trabajo: HB160-240

Tratamiento superficial: mecanizado

Proceso de fundición: fundición en arena de resina.

Pintura: imprimación y pintura facial.

Recubrimiento de la superficie: aceite decapado y revestido de plástico o cubierto con pintura anticorrosión

Grado de precisión: 2-3

Working temperature:(20±5) ℃

Embalaje: caja de madera contrachapada

Tiempo de espera

|

Cantidad (piezas) |

1 - 100 |

> 100 |

|

Plazo de entrega (días) |

30 |

Ser negociado |

Los productos de riel de tierra con ranura en T de hierro fundido también se conocen como: riel de tierra, riel de tierra con ranura en T, viga de tierra, hierro con ranura de tierra, hierro con ranura de cimientos, plataforma con ranura en T simple, riel de tierra de hierro fundido.

El objetivo principal del riel de tierra con ranura en T de hierro fundido es diseñarlo y ensamblarlo en una plataforma de viga fundida basada en los puntos fijos del equipo. Se utiliza principalmente para el montaje, prueba, soldadura e inspección de equipos grandes.

Ventajas del producto

Las ventajas materiales de los rieles de tierra con ranura en T de hierro fundido:

Las ventajas de los rieles de tierra con ranura en T de hierro fundido: al utilizar rieles de tierra de hierro fundido, no es necesario convertirlos en plataformas grandes, lo que ahorra costos de material y ocupa un espacio pequeño, lo que resulta en una alta rentabilidad.

El material del riel de tierra con ranura en T de hierro fundido es hierro fundido gris de alta resistencia HT200-250, con una dureza de superficie de trabajo de HB170-240. La pieza fundida se ha sometido a dos rondas de recocido artificial a 600 ℃ -700 ℃ o envejecimiento natural durante 2-3 años para eliminar completamente la tensión interna, con precisión estable y buena resistencia al desgaste.

Resin Sand Casting: How Guide Rail Manufacturing Ensures Stability

Precision in linear guide rails starts with manufacturing excellence. Storaen uses advanced resin sand casting to engineer heavy duty linear guide rails that deliver unmatched stability for aerospace, automotive, and heavy industry applications. Here’s how our process ensures reliability and performance across all guide rail types:

1. Material Excellence: HT200-HT300 Cast Iron for Industrial Demands

Resin sand casting begins with selecting HT200-HT300 gray cast iron (160–240HB hardness), chosen for:

Balanced Strength: 200–300MPa tensile strength supports 5–50 tons of moving equipment, ideal for heavy duty linear guide rails.

Stress Resistance: Uniform grain structure reduces internal stress by 40% vs. green sand casting, minimizing warping in 10°C–40°C environments for consistent machine guide rails performance.

2. Precision Molding for Complex Geometries

Self-hardening resin sand enables intricate guide rail types with tight tolerances:

CNC-Pattern Accuracy: T-slot dimensions (14–36mm width, 8–20mm depth) achieved with ±0.1mm precision for seamless integration with automation systems.

Core Stability: Internal cores maintain 0.05mm/m straightness, preventing defects and ensuring Class 2–3 flatness (≤0.02mm/m for 2000mm rails)—critical for precision alignment.

3. Heat Treatment for Durability & Stability

A 3-step process enhances rail performance:

Stress Relieving (550°C/4h): Eliminates 90% of casting stress to prevent deformation during machining/transport.

Normalizing: Refines grain structure for 2x longer wear resistance in high-cycle applications (10,000+ load cycles).

Surface Grinding: Finishes to Ra ≤1.6μm for smooth motion and minimal friction in automated systems.

4. Customizable Sizing & Load Capacity

Storaen adapts to all guide rail size and load needs:

Standard Range: 1500–4000mm length, 200–500mm width for common use; custom sizes up to 6000mm for oversized machinery.

Reinforced Design: Web structures increase load capacity by 30% (up to 80 tons/m) without added weight, ideal for aerospace assembly requiring precision and mobility.

5. Storaen’s Casting Advantage

Versatility: Produces all guide rail types—from lightweight precision rails to rugged heavy-duty models—with equal accuracy.

Quality Assurance: 3D laser scanning/CMM testing ensures compliance with GB/T 1958-2017/ISO 1101, backed by a 1-year warranty against dimensional drift.

Efficiency: 500PCS/day capacity delivers standard rails in 7 days, custom solutions in 4–6 weeks—balancing speed and stability.

Stability in linear guide rails is engineered, not accidental. Storaen’s resin sand casting combines premium materials, precision molding, and rigorous heat treatment to deliver heavy duty linear guide rails and machine guide rails that meet the toughest industrial demands. Explore our guide rail types today and experience the difference advanced manufacturing makes in equipment performance and longevity.

How Guide Rails Replace Cast Iron Surface Plates for Cost Savings

Traditional cast iron surface plates dominate industrial assembly and inspection, but their bulk, fixed sizing, and high maintenance costs challenge modern manufacturing efficiency. Storaen introduces linear guide rails as a cost-effective alternative, delivering precision, flexibility, and up to 30% total cost savings compared to conventional plates. Here’s how our guide rail types redefine industrial workholding:

1. Space-Saving Design: 50% Footprint Reduction

Cast iron plates (e.g., 2000x1500mm) require extensive floor space and heavy foundations, but Storaen’s heavy-duty linear guide rails offer modular, streamlined solutions:

Vertical & Horizontal Flexibility: Vertical guide rails (e.g., 1500mm height models) mount vertically on walls or stands, creating 3D assembly workspaces without sacrificing floor area—ideal for compact robotic cells or automated welding stations.

Customizable Lengths: Standard guide rail size ranges from 1000–4000mm, with seamless splicing for oversized applications (up to 6000mm), reducing material waste by 40% versus cutting-to-size cast iron plates.

2. Cost-Effective Precision Without Compromise

While cast iron plates achieve Class 2 flatness (≤0.02mm/m), Storaen’s ground-finish linear guide rails match this accuracy at 30% lower guide rail price:

Material Efficiency: HT200 cast iron construction (180HB hardness) uses 25% less material than solid surface plates while maintaining 50 tons/m load capacity, balancing rigidity and economy.

Reduced Maintenance: Anti-corrosion pickling oil finishes (5μm thickness) protect against coolant and humidity, extending service life by 2x compared to uncoated plates that require annual resurfacing (a $5,000+ cost for large plates).

3. Adaptability for Dynamic Workflows

Fixed cast iron plates struggle with changing production needs, but our guide rail types excel in versatility:

Modular T-Slot Design: 14–36mm wide slots (±0.1mm tolerance) accept quick-release clamps, robotic arms, or measurement tools, enabling 5-minute fixture reconfiguration versus 2+ hours for plate-based setups.

Heavy Duty Performance: Reinforced heavy duty linear guide rails (80 tons/m load capacity) support large equipment like stamping press components or aerospace fuselage sections, replacing multi-plate assemblies with single rail systems that simplify alignment.

4. Storaen’s Value Proposition: More Than Just Cost Savings

Rapid Deployment: Pre-machined rails ship ready for installation, cutting setup time by 60% compared to leveling and anchoring cast iron plates.

Custom Solutions: Need anti-magnetic coatings for electronics assembly or oversized guide rail size for wind turbine manufacturing? Our OEM team delivers tailored machine guide rails in 4–6 weeks, with no minimum order surcharges.

Quality Assurance: Every rail meets GB/T 1958-2017 geometric tolerances and includes a 1-year warranty—eliminating the risk of investing in underperforming budget alternatives.

5. Applications Where Cost Savings Meet Performance

Automotive Assembly: Replace 3m² cast iron plates with two 2000mm heavy-duty linear guide rails, saving $10,000 in upfront costs and 20% floor space for engine block alignment.

Aerospace Tooling: Lightweight linear guide rails (30% lighter than equivalent plates) reduce crane load requirements during wing component inspection, lowering operational energy costs.

General Machining: Portable guide rail types (50–100kg weight) eliminate the need for permanent plate installations, ideal for job shops with frequent equipment reconfiguration.

Don’t let outdated cast iron plates drain your budget and floor space. Storaen’s linear guide rails deliver the precision you need at a fraction of the cost, with modularity to future-proof your operations. From heavy duty linear guide rails for industrial giants to customizable guide rail types for niche applications, we’re redefining value in workholding solutions. Explore our competitive guide rail price options today and start saving without sacrificing performance.

Dibujo de detalle del producto

-

-

Descripción del texto de la imagen 1

Descripción del texto de la imagen 1 -

-

Parámetro del producto

Especificación y modelo (largo x ancho x alto) (unidad: mm)

1500x150x150 1500x200x150 1500x250x300 1500x300x400

2000x200x300 2000x250x300 2000x300x350 2000x350x350

2500x200x300 2500x250x300 2500x300x350 2500x300x400

2750x200x300 2750x250x300 2750x300x350 2750x300x400

3000 * 300 * 300 3000 * 300 * 350 3000 * 300 * 400 3000 * 320 * 400

3200 * 300 * 300 3200 * 300 * 350 3200 * 300 * 400 3200 * 320 * 400

3500 * 300 * 300 3500 * 300 * 350 3500 * 300 * 400 3500 * 320 * 400

4000x300x300 4000x300x350 3500x300x400 4000x320x400

4500x300x350 4500x300x400 4500x320x400 4500x350x400

5000x300x400 5000x350x400 5000x400x450

Especificación técnica del riel guía de piso con ranura en T de hierro fundido:

|

Material |

HT200-300 |

|

Especificación |

1500-4000 mm de longitud o personalizar |

|

Superficie |

Ranuras en T |

|

Dureza de la superficie de trabajo. |

HB160-240 |

|

Tratamiento de superficies |

mecanizado |

|

Proceso de fundición |

fundición de arena de resina |

|

Cuadro |

imprimación y pintura facial |

|

Revestimiento de la superficie |

aceite decapado y plastificado o cubierto con pintura anticorrosión |

|

Temperatura de trabajo |

(20±5) ℃ |

|

Grado de precisión |

2-3 |

|

embalaje |

caja de madera contrachapada |

Relacionado PRODUCTOS

NOTICIAS RELACIONADAS

Thread Plug Gauge Requires Careful Handling

In the world of manufacturing and engineering, precision is non-negotiable—especially when it comes to threads, which are critical components in machinery, construction, and everyday products.

Surface plate calibration

In today's world, where precision and accuracy are crucial in various industries, the use of granite inspection tables and granite surface plates has become increasingly popular.

Ring Gauge Ensures Machining Accuracy

In the world of precision engineering, manufacturing, and quality control, accuracy is the cornerstone of reliability.