Srp . 05, 2025 09:55 Zpět na seznam

The Unique Properties of a Block of Granite for Industrial Use

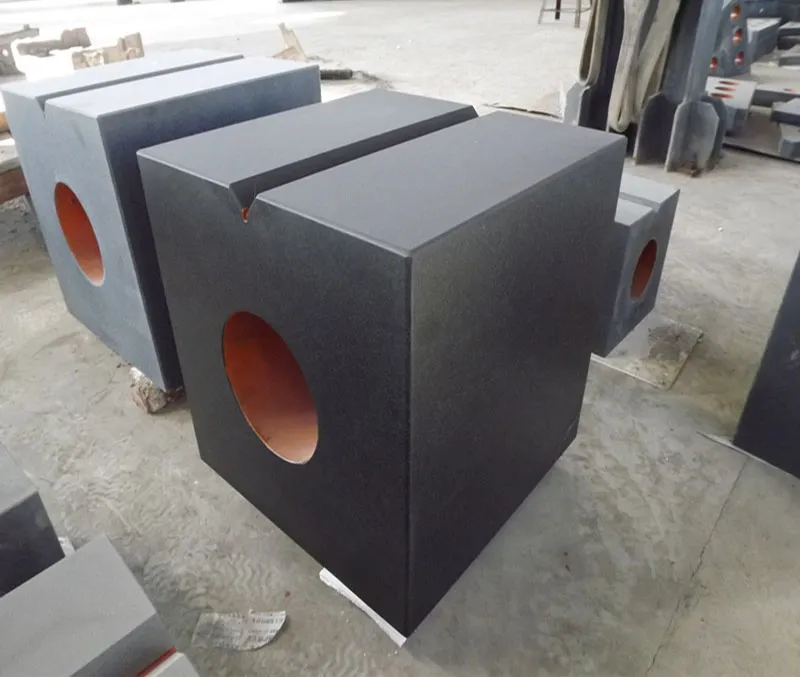

In industrial manufacturing and precision measurement, the reliability of materials directly impacts operational accuracy, and a block of granite has emerged as an indispensable resource. As a wholesaler, offering granite inspection block and granite stone blocks alongside various granite products ensures that clients across sectors can access solutions tailored to their needs. Storaen (Cangzhou) International Trading Co., a leader in industrial materials, has developed high-quality granite stone blocks and specialized granite inspection block models, leveraging granite’s inherent properties to set new standards in durability and precision. With a focus on quality craftsmanship, customization, and sustainable practices, the company enables wholesalers to provide products that enhance industrial efficiency, reduce maintenance costs, and ensure long-term reliability.

Block of Granite Core Physical Properties

A block of granite possesses unique physical properties that make it ideal for industrial applications, standing out among other materials for its robustness and stability.

|

Physical Property |

Advantage for Industrial Use |

Application Example |

|

High Hardness (HS70+) |

Resists scratches and abrasions |

Work surfaces in machining shops |

|

High Compressive Strength |

Withstands heavy loads without cracking |

Foundational blocks for machinery |

|

Low Water Absorption |

Resists moisture damage and corrosion |

Components in humid manufacturing environments |

|

Dimensional Stability |

Minimal size changes with temperature |

Granite inspection block for precision measurement |

Granite Inspection Block Precision Applications

A granite inspection block is engineered to leverage granite’s stability, becoming a cornerstone of precision measurement and quality control processes.

|

Granite Inspection Block Funkce |

Industrial Benefit |

Sector Application |

|

Precision Measurement Reference |

Ensures consistent, accurate part inspections |

Aerospace component manufacturing |

|

Machinery Alignment |

Facilitates precise assembly of mechanical parts |

Automotive production lines |

|

Custom Sizing |

Adapts to unique testing requirements |

Heavy machinery quality control |

Granite Stone Blocks Industrial Versatility

Granite stone blocks offer versatility across industrial sectors, thanks to their durability and adaptability to diverse operational demands.

|

Industry |

Granite Stone Blocks aplikace |

Key Advantage |

|

Manufacturing |

Work surfaces for precision tasks |

Vibration resistance, stability |

|

Construction |

Foundational components for equipment |

Durability under continuous use |

|

Chemical/Pharmaceutical |

Surfaces in corrosive environments |

Low reactivity, moisture resistance |

Block of Granite Long-Term Cost Benefits

Investing in block of granite and related products yields long-term cost savings, making them a cost-effective choice for industrial operations.

|

Cost Aspect |

Block of Granite Advantage |

Long-Term Impact |

|

Maintenance |

Minimal repairs due to durability |

Lower ongoing operational costs |

|

Performance |

Consistent accuracy reduces waste |

Higher production efficiency |

|

Versatility |

Multi-purpose use |

Reduced need for specialized equipment |

Granite Inspection Block FAQS

What makes granite inspection block suitable for precision measurement?

Granite inspection block is suitable for precision measurement due to its exceptional dimensional stability and flat surface. Its low linear expansion coefficient ensures minimal size changes with temperature fluctuations, maintaining consistent reference points for measurements. The high hardness (HS70 or above) prevents surface wear, ensuring long-term flatness, while the smooth, ground finish provides a precise base for calibrating tools and inspecting part dimensions. These properties make it indispensable in industries where accuracy is critical, such as aerospace and automotive manufacturing.

How do granite stone blocks withstand harsh industrial environments?

Granite stone blocks withstand harsh industrial environments through their inherent physical properties. Their high compressive strength allows them to bear heavy loads without cracking, while low water absorption resists moisture damage and corrosion—key in humid or chemical-exposed settings. Additionally, their hardness (HS70+) protects against scratches and abrasions from machinery or tools, ensuring they maintain integrity even in high-traffic areas. These characteristics make them ideal for use in factories, construction sites, and chemical facilities.

What customization options are available for block of granite products?

Storaen (Cangzhou) International Trading Co. offers extensive customization options for block of granite products, including various sizes to fit specific industrial needs, from small blocks for lab use to large workstations. Clients can also request specific surface finishes, such as ultra-flat grinding for inspection applications, or custom shapes to integrate with existing machinery. These options ensure that the granite blocks align perfectly with unique operational requirements, enhancing their utility and value for industrial users.

How does Storaen (Cangzhou) International Trading Co. ensure the quality of granite stone blocks?

Storaen (Cangzhou) International Trading Co. ensures the quality of granite stone blocks through rigorous sourcing and manufacturing processes. The company selects premium granite from trusted suppliers, leveraging its strategic location in Botou to access high-quality raw materials. Each block undergoes strict testing for hardness, compressive strength, and dimensional stability, adhering to standards like JJG194-92. Skilled craftsmen perform precise grinding and finishing, and thorough quality checks at every production stage ensure consistency. This commitment to quality guarantees that the granite blocks meet the demanding needs of industrial clients.

Can block of granite be used in outdoor industrial settings?

Yes, block of granite is well-suited for outdoor industrial settings. Its low water absorption and resistance to moisture damage prevent degradation from rain, snow, or humidity, while its hardness withstands exposure to UV rays, temperature extremes, and physical impact. These properties make it ideal for outdoor applications such as foundational blocks for outdoor machinery, work surfaces in open-air manufacturing areas, or components in infrastructure projects. Storaen (Cangzhou) International Trading Co.’s granite blocks, with their durable construction, maintain performance even in harsh outdoor conditions, ensuring long-term reliability.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlZprávyAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseZprávyAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsZprávyAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesZprávyAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingZprávyAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlZprávyAug.05,2025

Související produkty