Pro . 17, 2024 03:14 Back to list

65mm Butterfly Valve Pricing and Options for Your Needs

Understanding the Pricing Factors of 65mm Butterfly Valves

When it comes to industrial applications, butterfly valves are crucial components used to regulate or isolate the flow of liquids and gases. With their unique design and functionality, they offer an efficient solution for controlling flow in pipes of various sizes. Among the numerous specifications available, the 65mm butterfly valve is a popular choice due to its versatility and ease of use. This article aims to explore the factors that influence the pricing of 65mm butterfly valves, helping potential buyers make informed decisions.

The Basics of Butterfly Valves

Butterfly valves are characterized by a rotating disk that sits in the path of the flow. When the valve is closed, this disk blocks the passage, while turning it parallel to the flow allows for unrestricted passage. Their compact design makes them suitable for applications in tight spaces, and they are commonly used in various sectors, including water treatment, HVAC systems, and chemical processing.

Key Factors Influencing Price

1. Material Composition The material used to manufacture the butterfly valve significantly affects its price. Common materials include stainless steel, cast iron, and PVC. Stainless steel valves tend to be more expensive due to their corrosion resistance and durability, making them ideal for harsh environments.

2. Design Specifications Different designs and sizes cater to specific applications. A 65mm butterfly valve might come in different configurations, such as wafer, lug, or flanged designs. Each configuration has its distinct advantages and pricing implications. For example, wafer-style valves are often less expensive than lug-style valves, which provide additional mounting flexibility.

3. Pressure Rating The pressure rating of a butterfly valve indicates its capacity to withstand internal pressures. Valves designed for high-pressure systems typically use more robust materials and manufacturing processes, resulting in higher prices. Buyers need to assess the pressure conditions of their applications to choose appropriately.

butterfly valve 65mm price

4. Actuation Methods Butterfly valves can be operated manually or automatically. Manually operated valves are generally less expensive than those with automated actuation systems, which can include electric, pneumatic, or hydraulic actuators. The complexity and type of actuation can substantially impact the overall cost.

5. Brand Reputation The manufacturer’s reputation and brand influence pricing. Established brands often command higher prices because they have proven reliability and quality over time. However, opting for less-known brands might lead to cost savings, albeit with a potential trade-off in quality and support.

6. Compliance and Certifications For many applications, especially in sensitive industries such as food processing or pharmaceuticals, it is vital for valves to comply with specific standards and certifications (such as ASTM or ANSI). Valves with these certifications may come at a premium due to the additional testing and quality assurance required.

7. Market Demand and Supply Like any commodity, the price of butterfly valves can fluctuate based on market demand and supply conditions. In times of increased infrastructure development or industrial activity, demand may outstrip supply, resulting in higher prices.

8. Additional Features Many butterfly valves come with features that enhance their performance or lifespan, such as soft seat technology for better sealing, or advanced coatings for chemical resistance. These added features can increase initial costs but may result in lower maintenance and replacement costs over time.

Conclusion

When considering the price of a 65mm butterfly valve, it is essential to take into account a multitude of factors, including material, design specifications, pressure ratings, actuation methods, brand reputation, compliance requirements, market conditions, and additional features. By understanding these variables, buyers can ensure they are not only making a cost-effective purchase but also selecting a valve that fits their specific operational needs. As the industrial landscape continues to evolve, staying informed about these pricing determinants will be crucial for making smart, cost-effective procurement decisions.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

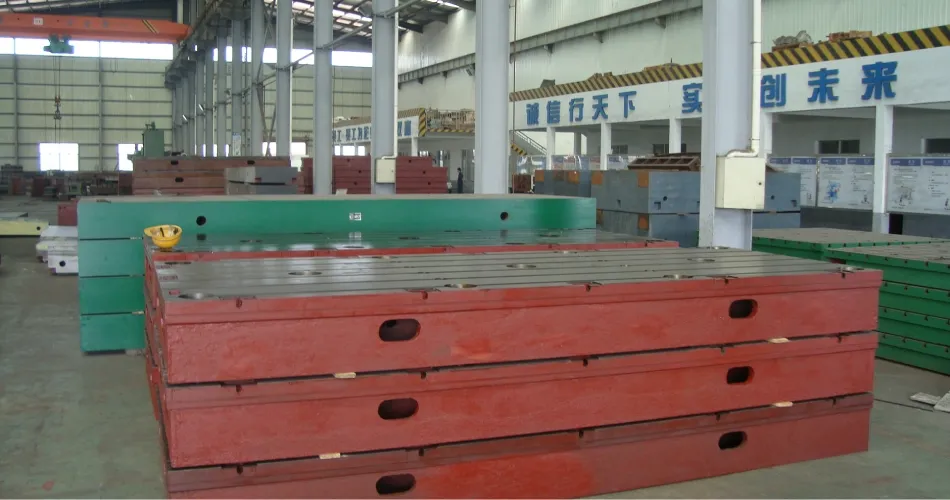

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS