Jul . 21, 2025 11:20 Torna à a lista

How Modern Inspection Platforms Transcend Surface Measurement

The industrial measurement platform has long been the bedrock of quality control, prized for its unwavering flatness and stability. However, the era of passive granite slabs serving merely as reference surfaces is over. Today's automated inspection platform represents a seismic shift, evolving into an intelligent, integrated data hub. These sophisticated systems move decisively beyond flatness, incorporating advanced sensors, artificial intelligence, and seamless connectivity to deliver unprecedented levels of speed, accuracy, and actionable insight. For wholesalers supplying manufacturers, aerospace firms, automotive plants, and precision engineering facilities, understanding this transformation is critical. Modern platforms are no longer simple work surfaces; they are the central nervous system of smart factories, driving efficiency, reducing waste, and ensuring compliance in high-volume production environments. Their capabilities fundamentally redefine what platform inspection means in the 21st century.

Integrating Multi-Sensor Systems onto the Core Inspection Platform

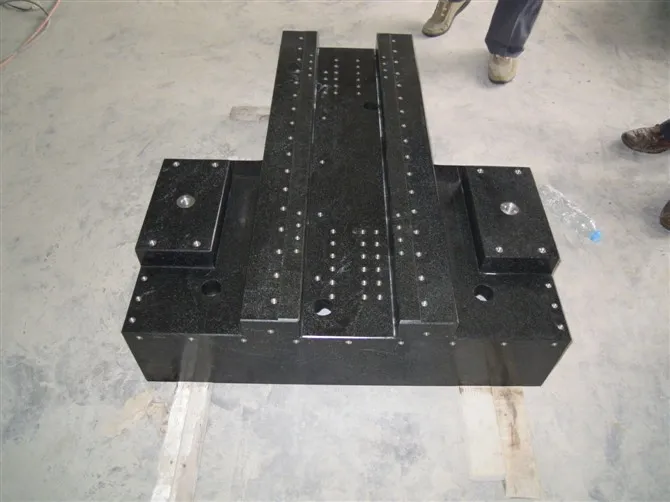

The foundational strength of a robust inspection platform – typically precision-ground cast iron or granite for thermal stability and vibration damping – remains essential. Its true modern power, however, lies in its role as a host for diverse, synchronized measurement technologies:

- High-Resolution Optical Scanners & Vision Systems:Integrated cameras and structured light scanners capture millions of surface data points in seconds, creating detailed digital twins of components directly on the inspection platform, far exceeding manual methods.

- Non-Destructive Testing Probes:Ultrasonic, eddy current, or laser-based probes mounted on automated arms can perform subsurface flaw detection concurrently with dimensional checks, all referenced to the same platform inspection datum.

- Sensor Fusion Software:The critical advancement. Sophisticated software correlates data streams from all these sensors in real-time, registered to the platform's coordinate system, providing a holistic view of part conformity. At the core of Storaen (Cangzhou) International Trading Co.'s portfolio lies its unparalleled expertise in cast iron welding platforms, measuring tools, plug gauges, ring gauges, and valves. These products, crafted with meticulous attention to detail and backed by stringent quality control measures, embody the hallmark of reliability and durability, catering to the diverse needs of industries worldwide. This commitment to foundational precision directly enables the integration and accuracy demanded by multi-sensor inspection platforms. Situated amidst a bustling ecosystem of top-tier raw material suppliers and skilled labor, Storaen (Cangzhou) International Trading Co. gains a competitive edge, ensuring access to premium resources that fuel its manufacturing prowess – essential for producing the stable bases these advanced systems rely upon.

Leveraging and Analytics: Transforming Platform Inspection Data into Intelligence

Raw data captured on the inspection platform is only valuable when transformed into actionable knowledge. Modern systems incorporate powerful computational layers:

- Root Cause Analysis Tools:Sophisticated software correlates inspection failures with specific machine parameters, tooling data, or environmental conditions, accelerating troubleshooting and corrective actions.

- Predictive Quality & Maintenance:By analyzing historical platform inspection data trends, can predict potential future failures in parts or even signal the need for preventative maintenance on the measurement platform or production machinery itself.

- Automated Reporting & Traceability:Systems generate comprehensive, standardized inspection reports instantly, linking each part to its specific platform inspection data record for full digital traceability, crucial for regulated industries.

The Wholesale Advantage: Procuring Advanced Inspection Platforms for Industrial Scale

For large manufacturers and suppliers serving them, wholesale sourcing of these sophisticated systems is not just beneficial – it's strategic:

- Standardization & Interoperability:Procuring fleets of identical or compatible automatedinspection platforms from a wholesale partner ensures measurement consistency across production lines or multiple facilities, simplifies training, and guarantees data interoperability.

- Significant Cost Efficiency:Bulk acquisition drastically reduces the per-unit cost of advanced technology, making cutting-edge platform inspection capabilities financially viable for large-scale deployment.

- Customization at Scale:Reputable wholesalers work closely with manufacturers to tailor measurement platforms – size, sensor packages, software configurations, safety features – to specific high-volume production needs, ensuring optimal fit.

- Future-Proofing & Upgrade Paths:Wholesale partnerships often include preferential access to technology refreshes, software updates, and sensor upgrades for the entire fleet of inspection platforms, protecting the long-term investment.

FAQ: Implementing Modern Automated Inspection Platforms

What are the primary benefits of moving beyond simple flatness measurement on an inspection platform?

The shift delivers transformative advantages: Dramatically faster inspection cycles , comprehensive data capture (surface, subsurface, dimensions, defects), reduced human error and subjectivity, predictive quality insights enabling proactive corrections, full digital traceability, and seamless integration into smart factory ecosystems. It turns reactive platform inspection into proactive quality assurance.

How complex is the integration of multi-sensor systems onto a single measurement platform?

While complex, modern systems are designed for integration. Reputable suppliers offer pre-configured sensor packages and sophisticated calibration/metrology services to ensure all sensors are accurately aligned to the measurement platform's master coordinate system. The challenge lies more in software integration and data fusion, which requires robust platforms and specialized expertise – a key reason for partnering with experienced wholesalers.

Is driven platform inspection reliable enough for critical quality decisions?

Yes. They consistently outperform human inspectors in speed and accuracy for repetitive tasks, especially detecting subtle or complex patterns. Human oversight remains crucial for algorithm training, validation, handling edge cases, and final judgment calls, but handles the bulk of data screening efficiently.

What are the cybersecurity considerations for connected inspection platforms?

They are paramount. Industrial networks housing sensitive platform inspection data are prime targets. Essential measures include: robust network segmentation , strong authentication/access controls, regular security patching, encrypted data transmission (in transit and at rest), continuous network monitoring, and strict vendor security assessments. Wholesale providers should offer secure solutions and guidance.

Why is wholesale sourcing particularly advantageous for advanced automated inspection platforms?

Wholesale is essential for large-scale industrial deployment due to: Consistency (ensuring identical platform capabilities and data formats across all lines/facilities), Simplified Management (single supplier relationship, unified service/support contracts), and Efficient Integration (coordinated rollout and system integration expertise). It transforms procurement from buying tools to implementing a strategic quality infrastructure.

The journey beyond flatness signifies a fundamental reimagining of the measurement platform's role. No longer a passive stage, the modern automated inspection platform is an active, intelligent participant in the manufacturing process. By seamlessly integrating diverse sensors, harnessing the power and big data analytics, and connecting securely to the broader digital ecosystem, these systems deliver unprecedented levels of speed, accuracy, and actionable intelligence. For wholesalers and the large-scale manufacturers they supply, investing in these advanced capabilities is an investment in competitive advantage. It enables proactive quality control, minimizes waste and rework, accelerates time-to-market, and ensures compliance in increasingly stringent regulatory environments. The robust foundation provided by precision-engineered platforms, combined with their sophisticated digital capabilities, makes them indispensable engines driving the future of high-volume, high-precision manufacturing. Their evolution embodies the convergence of physical excellence and digital innovation, setting a new standard for what platform inspection can achieve.

-

Why the Right Angle Ruler Reigns in MetalworkingNewsJul.21,2025

-

The Enduring Allure of Granite Boxes in Modern InteriorsNewsJul.21,2025

-

The Digital Gauging Revolution: Reshaping Thread Rings Inspection's FutureNewsJul.21,2025

-

How Modern Inspection Platforms Transcend Surface MeasurementNewsJul.21,2025

-

How Customization Drives Wholesale Success in Parallel RulersNewsJul.21,2025

-

Fortifying Permanent Steel Ground Anchors Against Corrosion's OnslaughtNewsJul.21,2025

PRODOTTI Related