Nov . 01, 2024 08:34 Back to list

Exploring Different Types of Strainers for Various Applications and Uses

Understanding Strainer Types A Focus on Strainer Type Y

In various industrial and engineering applications, the efficiency and reliability of fluid systems are paramount. One crucial component that plays a vital role in maintaining the integrity of these systems is the strainer. Strainers serve as a filtration solution to prevent debris, sediment, and other contaminants from entering critical equipment such as pumps, valves, and pipelines. Among the different types of strainers available, Strainer Type Y has gained popularity for its effectiveness and versatility.

Understanding Strainer Types A Focus on Strainer Type Y

One of the primary advantages of Strainer Type Y is its ease of maintenance. The strainer is equipped with a removable filter element, or screen, which can be easily accessed and cleaned or replaced without having to disconnect the entire system. This feature is particularly beneficial in systems where downtime can be costly. Regular maintenance of the strainer not only ensures optimal performance but also extends the lifespan of downstream equipment by preventing contaminants from causing undue wear and tear.

strainer type y

Y strainers are used in a variety of applications across multiple industries. In water treatment plants, for example, they are essential in filtering out sediments from raw water before it undergoes further processing. In HVAC systems, they help protect pumps and valves from debris that could lead to malfunctions. Furthermore, Strainer Type Y is prevalent in oil and gas applications, where it prevents pollutants from entering pipelines and machinery, thereby ensuring operational efficiency and safety.

Another critical aspect of Strainer Type Y is its ability to handle high flow rates. This characteristic makes it an ideal choice for larger systems where maintaining a consistent flow is crucial. The design ensures minimal pressure drop across the strainer, which means the system can operate efficiently without the strain that can occur with other types of strainers that may become clogged more quickly.

The selection of the right strainer type is pivotal. Factors such as the size of the piping, the nature of the fluid, and the level of filtration required should be considered. Strainer Type Y is available in various mesh sizes, allowing users to choose the right level of filtration for their specific needs. Whether the application involves large volumes of water or viscous fluids, the versatility of the Y strainer makes it a go-to option for engineers and facility managers.

In conclusion, Strainer Type Y is an indispensable component within fluid systems, providing an efficient and maintenance-friendly solution to contamination issues. Its robust design, ease of serviceability, and suitability for high-flow applications make it an ideal choice for a multitude of industries. By ensuring that systems remain free of harmful particles, Strainer Type Y plays a critical role in enhancing performance, safety, and durability in various applications. With proper selection and regular maintenance, these strainers contribute significantly to the longevity and efficiency of industrial processes.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

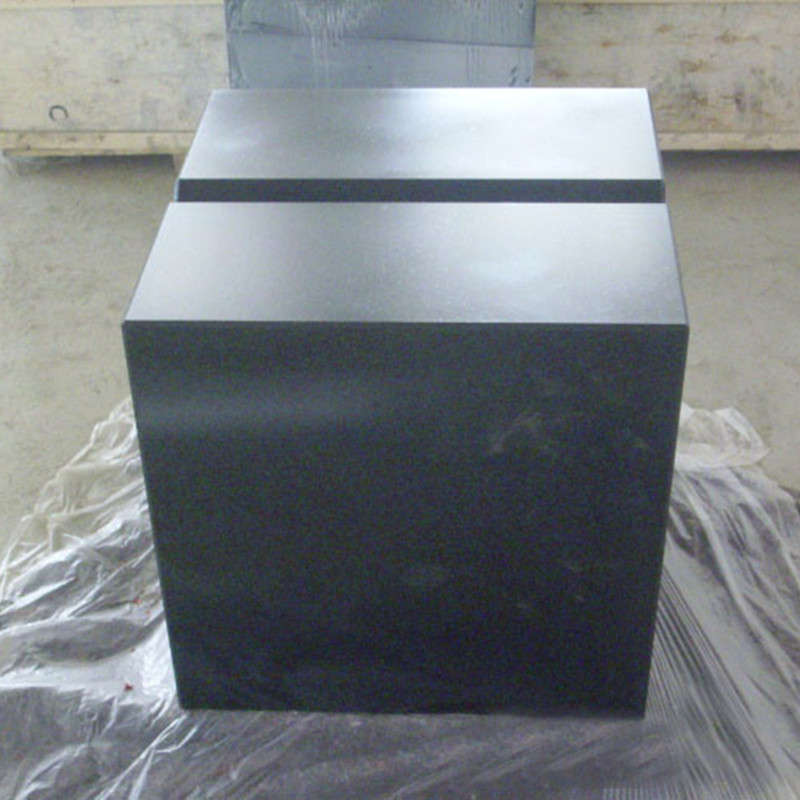

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS