Dec . 25, 2024 05:57 Back to list

Understanding Different Types of Snap Gauges for Precision Measurement Applications

Understanding Snap Gauge Types A Comprehensive Overview

Snap gauges are precision measuring tools used extensively in manufacturing and engineering to ensure the dimensional accuracy of various components. They are designed to quickly and accurately assess the size of an object, making them indispensable in quality control processes. In this article, we'll delve into the types of snap gauges, their functionalities, benefits, and applications.

What is a Snap Gauge?

A snap gauge, also known as a snap gauge micrometer or comparator, is a non-electric measuring device that translates the physical dimensions of an object into a measurable output. Snap gauges typically consist of a base, a measuring element, and a measuring jaw. The jaws are set to specific dimensions and can snap onto the object being measured, providing a clear indication of whether the component meets required specifications.

Types of Snap Gauges

1. Fixed Snap Gauges Fixed snap gauges have non-adjustable measurements and are used for checking components with established tolerances. They are designed to provide a quick pass or fail judgment based on whether the workpiece fits between the jaws. These types of gauges are most commonly used in high-volume manufacturing where consistency is critical.

2. Adjustable Snap Gauges Unlike fixed gauges, adjustable snap gauges allow the user to set the measurement to be checked. This flexibility makes them useful for inspecting a variety of parts with different specifications. Adjustability is typically achieved through a calibrated mechanism, which may include a micrometer screw, to fine-tune the settings to the desired dimension.

3. Go/No-Go Snap Gauges Go/No-Go snap gauges are designed with two ends - one marked Go and the other No-Go. The Go end should fit the object if it is within acceptable limits, while the No-Go end should not. This type is straightforward and efficient for ensuring parts are manufactured within tolerances without needing to take precise measurements.

4. Electronic Snap Gauges A more modern development, electronic snap gauges incorporate digital readouts. These gauges can provide more precise measurements and offer functionalities such as data logging and connectivity with other systems for enhanced quality control processes. They are suitable for industries where precision and data analysis are paramount.

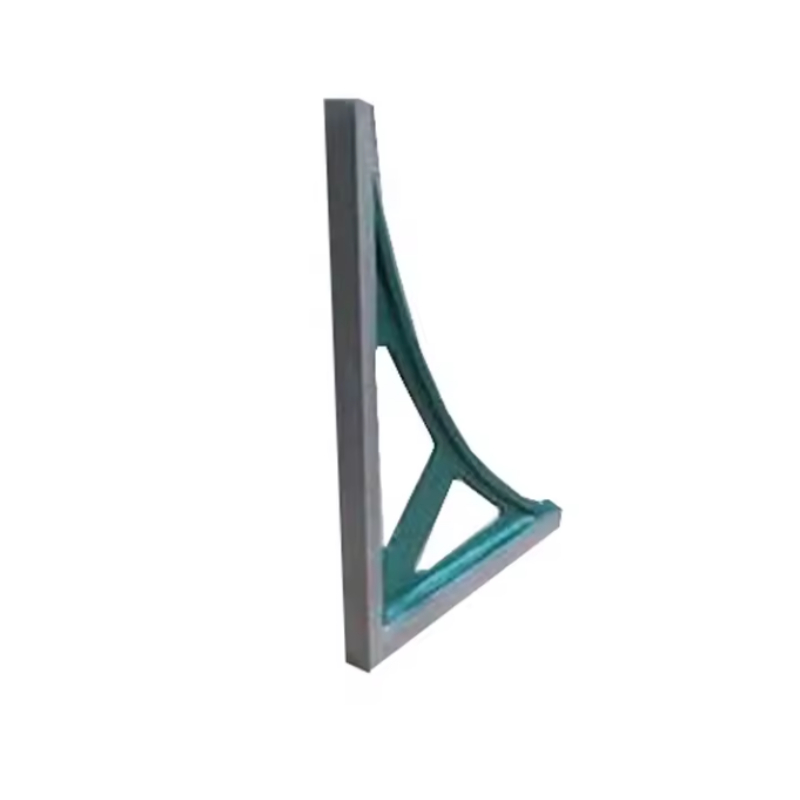

snap gauge types

Benefits of Using Snap Gauges

Snap gauges offer numerous advantages in manufacturing and inspection processes. Their primary benefits include

- Speed Snap gauges can assess a part's size almost instantly, making them ideal for high-production environments. - Simplicity The ease of use reduces the learning curve for operators, allowing employees to quickly become proficient in measurement. - Consistency With fixed designs or calibrated settings, snap gauges provide reliable measurements, ensuring that products consistently meet specified tolerances. - Cost-Effectiveness Compared to other advanced measuring tools, snap gauges are relatively affordable, making them accessible for a wide range of businesses.

Applications in Various Industries

Snap gauges find applications across numerous sectors, including

- Automotive Manufacturing Ensuring the precise dimensions of engine components and chassis parts. - Aerospace Measuring critical components where precise dimensions are vital for safety and performance. - Consumer Electronics Ensuring that housing parts and internal components fit together seamlessly. - Medical Devices Checking the dimensional accuracy of components that must meet strict regulatory requirements.

Conclusion

In conclusion, snap gauges are essential tools in many industries, providing fast and reliable measurements to uphold quality standards. Understanding the various types of snap gauges and their applications can help businesses optimize their measurement processes and ensure product reliability. As technology advances, incorporating more sophisticated gauges can further enhance accuracy and efficiency in manufacturing practices.

-

thread-plug-gauge-our-promise-of-measurement-excellenceNewsAug.22,2025

-

gauge-pin-class-reflecting-quality-legacyNewsAug.22,2025

-

check-valve-types-for-high-rise-buildingsNewsAug.22,2025

-

water-control-valve-for-irrigation-systemsNewsAug.22,2025

-

gate-valve-with-soft-seal-technologyNewsAug.22,2025

-

y-type-strainer-for-oil-and-gas-applicationsNewsAug.22,2025

Related PRODUCTS