Dec . 07, 2024 04:13 Back to list

Analysis and Importance of Check Valves in Pumping Systems

Understanding Pump Check Valves Importance, Function, and Application

Check valves are crucial components in various pumping systems, designed to control the flow of fluids and prevent backflow. Among the different types of check valves, pump check valves stand out for their specific application in pumping devices, ensuring efficiency and operational reliability. This article delves into the significance, functionality, and applications of pump check valves.

Importance of Pump Check Valves

Pump check valves serve an essential role in maintaining the integrity of pumping systems. When a pump is turned off, the fluid can flow back into the source if there is no proper sealing mechanism in place. This backflow can lead to several issues, including potential damage to the pump, loss of priming, and contamination of the fluid being pumped. By preventing backflow, check valves help maintain pressure within the system, ensuring that the pump remains operational and efficient.

In applications where liquids must be transported over long distances or where fluctuating pressures are common, the presence of check valves becomes even more critical. They aid in protecting downstream equipment from damage caused by surges or reverse flow, which can compromise both the system's performance and longevity.

Functionality of Pump Check Valves

Pump check valves operate on a simple yet effective principle. They allow fluid to flow in one direction while automatically preventing it from flowing back. This one-way flow is facilitated by a movable disc or ball mechanism that opens when pressurized fluid flows in the intended direction and closes when there is a drop in pressure or a reverse flow occurs.

The design of a pump check valve can vary, with the most common types being swing check valves, lift check valves, and diaphragm check valves

1. Swing Check Valves These utilize a hinged disc that swings open to allow flow and swings shut when backflow occurs. They are typically used in larger piping systems where the risk of backflow is significant.

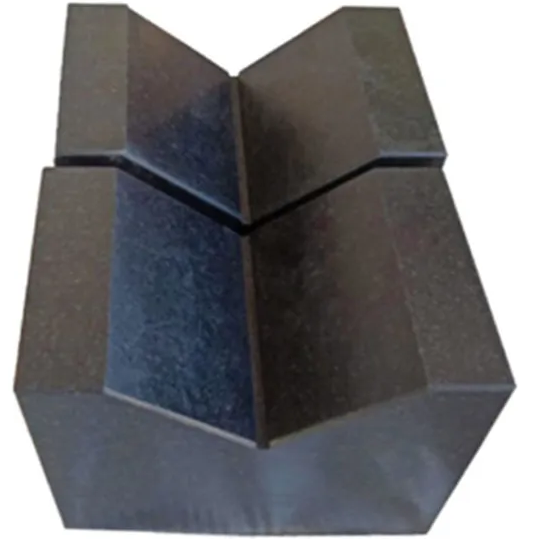

pump check valve

2. Lift Check Valves Designed with a disc that lifts off its seat as fluid flows in, this type is more suitable for applications with high fluid velocities. The disc closes as the flow decreases, effectively preventing backflow.

3. Diaphragm Check Valves Utilizing a flexible diaphragm, these valves respond to fluid pressure changes, making them ideal for situations where leakage prevention is critical. They are often used in chemical and food processing industries.

Applications of Pump Check Valves

The applications of pump check valves span across various industries due to their reliability and effectiveness. Some common applications include

- Water Supply Systems In municipal water supply, check valves prevent the backflow of treated water into untreated sources. They ensure that pressure is maintained within the distribution network. - Industrial Processes Many manufacturing processes rely on check valves to maintain flow and prevent contamination. They are especially critical in chemical processing, where the backflow of hazardous substances can pose significant risks.

- HVAC Systems In heating, ventilation, and air conditioning systems, pump check valves help prevent the reverse flow of refrigerants and maintain system efficiency.

- Pump Systems Various types of pumps, including centrifugal and positive displacement pumps, utilize check valves to ensure proper functionality and prevent damage from backflow.

Conclusion

In summary, pump check valves are integral to the efficient operation of various fluid handling systems. Their ability to prevent backflow directly influences the performance, safety, and longevity of pumping equipment. As industries continue to evolve, the importance of reliable check valves only becomes more pivotal, underscoring the need for thoughtful design and maintenance of these essential components. When considering the design and operation of any pumping system, the inclusion of adequate check valves should be a top priority to ensure optimal performance and prevent potential hazards.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS