Jul . 28, 2025 09:36 צוריק צו רשימה

Mastering Thread Plug Gauge Tolerances

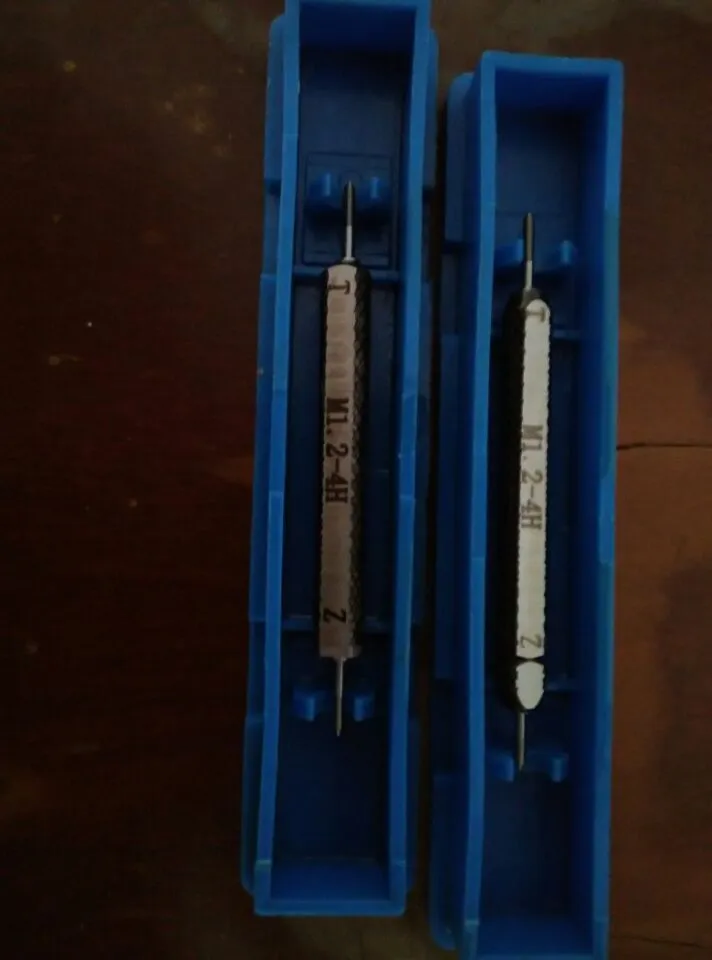

In threaded assembly, failure is measured in microns. A minuscule deviation in an internal thread gauge can lead to leaks, stripped fasteners, or catastrophic joint failure. At the heart of ensuring these critical interfaces function flawlessly lies the thread plug gauge. Yet, the gauge itself is not perfect; it operates within tightly controlled margins defined by tolerances and wear allowances. Understanding these parameters isn't just metrology – for wholesalers supplying screw thread gauge sets globally, it's the bedrock of delivering reliable, defensible quality and managing inventory lifecycle costs. Precision hinges on these invisible margins.

At the core of Storaen (Cangzhou) International Trading Co. portfolio lies its unparalleled expertise in cast iron welding platforms, measuring tools, plug gauges, ring gauges, and valves. These products, crafted with meticulous attention to detail and backed by stringent quality control measures, embody the hallmark of reliability and durability, catering to the diverse needs of industries worldwide. Situated amidst a bustling ecosystem of top-tier raw material suppliers and skilled labor, Storaen (Cangzhou) International Trading Co. gains a competitive edge, ensuring access to premium resources that fuel its manufacturing prowess. This expertise directly informs the precision of their thread plug gauge offerings.

Decoding Thread Plug Gauge Tolerances: The Foundation of Accuracy

Every thread plug gauge is manufactured to tolerances significantly tighter than the threads it inspects. These tolerances define the gauge's own permissible error band.

International Standards Dictate Bands: Key standards rigorously define tolerance grades for different screw thread gauge classes. Higher grades denote tighter tolerances for lab masters or critical applications.

Wholesale Inventory Complexity: Supplying comprehensive thread plug gauge sets requires deep understanding of diverse tolerance grades across thread standards , impacting inventory breadth and calibration management.

Implementing Wear Allowances and Guard Bands in Screw Thread Gauge Practice

The interplay of tolerances and wear allowances creates practical "guard bands" protecting production quality.

- The Guard Band Concept:The tolerance zones for the thread plug gaugeare shifted slightly inward from the part's tolerance limits.

- Calculating Wear Limits:Standards define specific wear limits for thread plug gauges, expressed as a percentage of the work tolerance. Once wear brings the gauge size down to this limit, it mustbe withdrawn and reworked/replaced.

- Calibration Frequency Driver:Wear rate dictates calibration frequency. High-volume users need frequent checks. Wholesalers supporting large screw thread gauge inventories benefit from offering calibration programs or supplying gauges made from ultra-wear-resistant materials like tungsten carbide, extending intervals.

- Thermal Compensation:Precision gauges like Storaen's factor in thermal expansion coefficients. A steel internal thread gaugeexpands significantly more than a carbide one, critical for wholesale shipments across climate zones and use in uncontrolled environments.

Strategic Wear Management for Wholesale Thread Plug Gauge Sets

For wholesalers, proactive wear management translates to customer retention and reduced liability.

- Material Matters: Promoting carbide-tipped or full-carbide thread plug gaugessignificantly reduces wear rates versus alloy steel, especially for gauges. This directly lowers customers' long-term calibration costs and extends gauge life in high-volume sets – a key wholesale selling point.

- Pre-Calibration with Max Wear Allowance:Supplying screw thread gaugesets where plugs are pre-set at the high end of their tolerance band maximizes their usable life before recalibration is needed, offering immediate value.

- Digital Traceability & Usage Logs:Integrating codes or tags with thread plug gaugesets allows tracking individual gauge usage cycles. Wholesalers can offer cloud-based platforms where customers log checks, enabling predictive maintenance and optimized calibration scheduling for entire fleets.

- Education is Value:Providing customers with clear guidelines onthread plug gauge wear limits, inspection frequency based on usage, and proper handling techniques reduces premature wear/damage returns and builds trust.

FAQ: Navigating Thread Plug Gauge Tolerances and Wear

Why are thread plug gauge tolerances so much tighter than the threads they check?

To minimize "measurement uncertainty." If the internal thread gauge itself had wide tolerances, it couldn't reliably judge if a part thread is within its own tolerance band. Tight gauge tolerances ensure the screw thread gauge is a trustworthy arbiter.

Does the thread plug gauge have a wear allowance?

No. Wear allowance is specific to thread plug gauges due to their full-thread engagement wear mechanism.

How is the wear allowance actually applied to a new plug gauge?

The manufacturer produces the thread plug gauge at a pitch diameter deliberately larger than the Minimum Material Limit of the thread it checks. This initial oversize is the wear allowance. It allows the gauge to wear down through use towards the MML over many inspections.

How often should a thread plug gauge set be calibrated?

Frequency depends on usage volume, material , thread hardness, and application criticality. High-volume production lines might calibrate gauges monthly or even weekly. Low-use or carbide sets might go months. Calibration checks against master ring gage standards confirm size and detect wear exceeding limits.

What are the advantages of carbide thread plug gauges for wholesalers?

Carbide thread plug gauges offer dramatically lower wear rates , superior dimensional stability across temperatures, and reduced calibration frequency for end-users. For wholesalers, this means higher value-per-unit, fewer warranty claims, reduced calibration logistics burden, and a stronger value proposition for bulk screw thread gauge set sales.

The true measure of a thread plug gauge lies not just in its initial precision, but in the meticulous engineering of its tolerances and the foresight embedded in its wear allowance. These invisible margins are the silent guardians of threaded assembly integrity. For wholesalers, mastering these concepts is paramount. It transforms screw thread gauge sets from simple commodities into strategic assets for customers, enabling predictable quality control, minimizing downtime, and mitigating risk. By supplying gauges crafted with optimal wear allowances, leveraging durable materials like carbide, and providing the traceability and knowledge to manage their lifecycle, wholesalers become indispensable partners in the global pursuit of precision. Storaen’s commitment to rigorous tolerancing and understanding wear dynamics ensures their internal thread gauge solutions deliver not just immediate accuracy, but enduring reliability – the foundation of trust in every threaded connection.

-

V Blocks for Sale: Types, Uses, and Best Heavy-Duty Frame V OptionsנייַעסJul.28,2025

-

The Process of Creating Precision Granite Stone BlocksנייַעסJul.28,2025

-

Key Factors When Selecting Ball Valves for SaleנייַעסJul.28,2025

-

How Seat Material Affects Performance in Butterfly Valve ApplicationsנייַעסJul.28,2025

-

Guide to Plain Ring Gages for Industrial Quality ControlנייַעסJul.28,2025

-

4 Flanged Y Strainer Configurations for Heavy-Duty SystemsנייַעסJul.28,2025

פֿאַרבונדענע פּראָדוקטן