Nov . 06, 2024 03:41 Back to list

Precision Taper Gauge for Accurate Measurements 1 to 15mm Range

Understanding Taper Gauge 1 15mm A Comprehensive Overview

In various industries, precision measurement is critical for ensuring the quality and functionality of products. One such instrument that plays a significant role in achieving precise measurements is the taper gauge, specifically the Taper Gauge 1 15mm. This tool is widely used in fields such as manufacturing, engineering, and construction due to its unique design and functionality.

What is a Taper Gauge?

A taper gauge is a specialized measuring tool designed to determine the depth, angle, or taper of a surface. It is particularly beneficial for assessing the specifications of various components, enabling engineers and technicians to maintain consistent quality standards. The 1 15mm designation refers to the dimensions and taper angle of the gauge, indicating that it has a taper angle of 1 degree with a width of 15mm.

Features and Specifications

The Taper Gauge 1 15mm exhibits several key features that enhance its usability

1. Material and Durability Typically made from high-quality steel or other durable materials, taper gauges are designed to withstand wear and tear. This resilience ensures that they can provide accurate measurements over extended periods.

2. Precision The gauge allows users to measure tapers with great accuracy, which is crucial in applications where even minor discrepancies can lead to significant issues.

3. Portability The compact size of the Taper Gauge 1 15mm makes it easy to carry and use in various settings. This convenience is particularly advantageous for fieldwork, where quick and accurate measurements are essential.

4. Ease of Use Designed with user-friendliness in mind, taper gauges often come with clear markings and a straightforward design. This makes it easy for professionals to take measurements without extensive training.

taper gauge 1 15mm

Applications

The Taper Gauge 1 15mm is utilized in numerous applications across different sectors

1. Manufacturing In the manufacturing industry, taper gauges are used to inspect the dimensions of machined parts. They help verify that components fit together correctly, ensuring the integrity of final products.

2. Construction Builders and contractors often use taper gauges when working on projects that require precise angles and measurements, such as framing walls or installing ramps. The gauge ensures that structures meet safety and design specifications.

3. Automotive and Aerospace In the automotive and aerospace sectors, precision is paramount. Taper gauges assist engineers in measuring the profiles of various components, ensuring that they meet stringent regulatory standards.

4. Woodworking Woodworkers rely on taper gauges to achieve accurate angles and fits in their projects. This attention to detail can greatly enhance the quality of woodwork, resulting in more aesthetically pleasing and functional pieces.

Maintenance and Care

To ensure the longevity and accuracy of the Taper Gauge 1 15mm, proper maintenance is essential. Users should regularly clean the gauge to remove dust and debris, which can interfere with measurements. Additionally, storing the gauge in a protective case can prevent damage when not in use. Regular calibration may also be necessary to maintain its precision, depending on the frequency of use and the tolerances required for specific applications.

Conclusion

The Taper Gauge 1 15mm is an invaluable tool in various industries, providing essential measurements that maintain quality and safety standards. Its robust construction, precision capabilities, and ease of use make it a preferred choice among professionals. By understanding its features and applications, users can leverage this tool effectively to enhance their work quality and efficiency. Whether you are in manufacturing, construction, or another field, incorporating a taper gauge into your toolkit can lead to significant improvements in your project outcomes.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

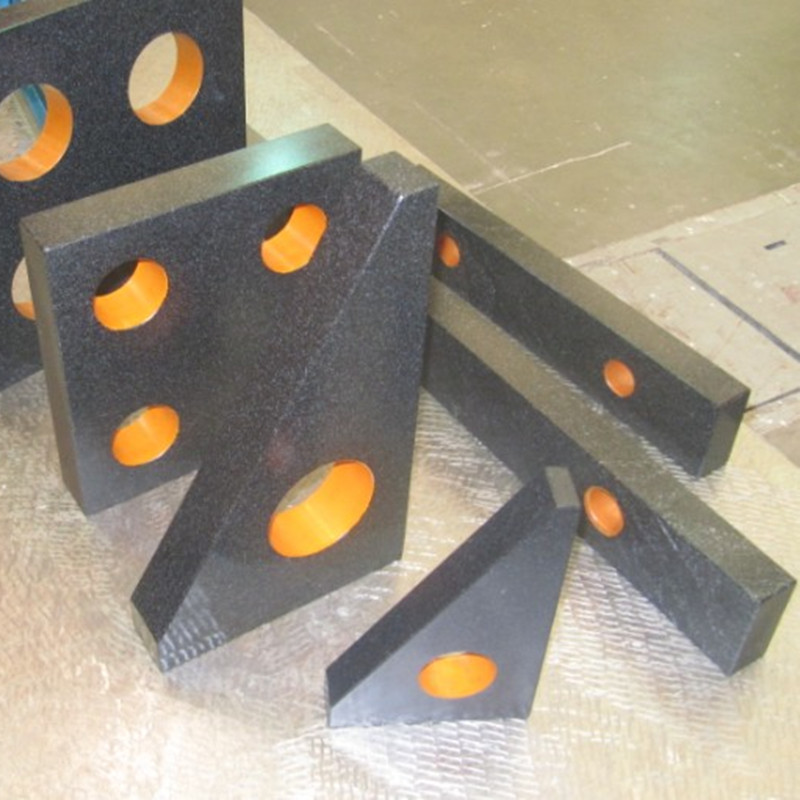

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS