Nov . 24, 2024 17:53 Back to list

Precision Measurement Tools for Snap Gauge Set Applications and Uses

Understanding the Snap Gauge Set A Precision Tool for Accurate Measurements

In the realm of manufacturing and engineering, precision is paramount. One tool that plays a critical role in achieving that precision is the snap gauge set. This set of measuring instruments is designed to provide accurate and reliable dimensional measurements, especially in the evaluation of cylindrical and flat surfaces. In this article, we will delve into the characteristics, applications, and advantages of snap gauges, as well as their significance in various industries.

What is a Snap Gauge Set?

A snap gauge set consists of a series of gauges used to measure the external dimensions of an object. Unlike traditional calipers, snap gauges offer a more straightforward and faster way of determining if parts meet specified tolerances. Typically composed of two parts — the body and the measuring anvils or heads — a snap gauge is designed to snap onto a workpiece, hence the name. The operator simply places the workpiece between the anvils, and if the part fits within the specified limits, it is deemed acceptable.

Snap gauges come in various types, including fixed and adjustable gauges. Fixed snap gauges are set to a specific dimension and can be used to check parts against this dimension. Adjustable snap gauges allow operators to modify the dimension as needed, making them versatile tools in a dynamic production environment.

Applications of Snap Gauge Sets

Snap gauge sets are widely used in a variety of industries, including automotive, aerospace, electronics, and metalworking. They are especially prevalent in contexts where parts must adhere to strict quality control measures. Here are some notable applications

1. Quality Control In manufacturing, maintaining quality is essential. Snap gauges are commonly employed in quality control processes to ensure that produced parts conform to design specifications. By providing quick feedback on dimensional accuracy, they help prevent defective parts from entering the supply chain.

2. Engine Components Given the stringent tolerances required in engine manufacturing, snap gauges are utilized to measure components like pistons, cylinders, and gears. These measurements are critical to ensure that all parts fit together flawlessly, which is essential for optimal engine performance.

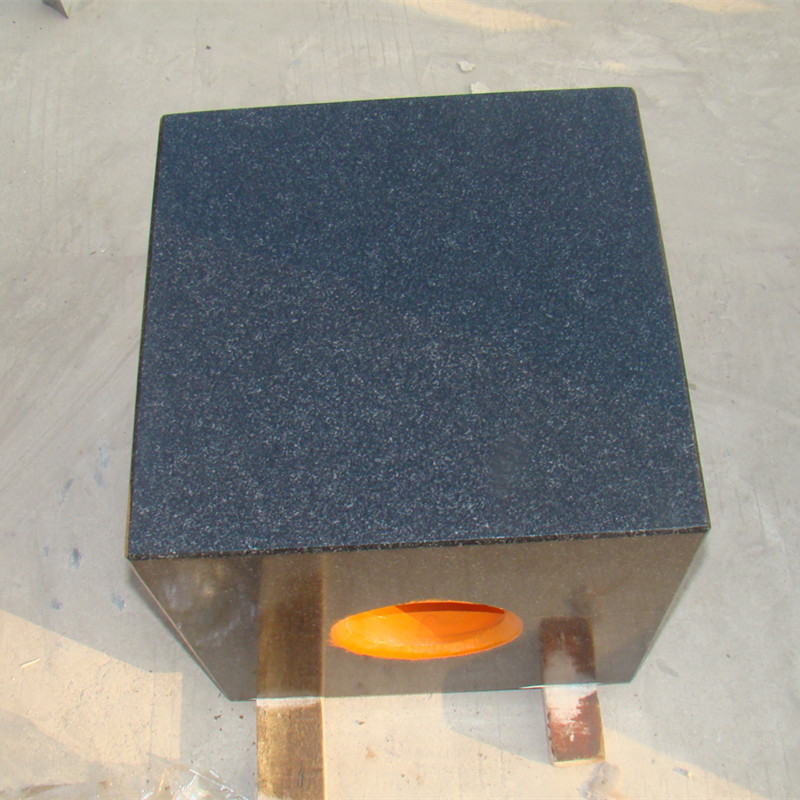

snap gauge set

3. Aerospace Parts In the aerospace industry, snap gauges are invaluable for measuring critical components such as turbine blades and fuselage sections. The high standards for safety and performance demand that all parts be manufactured to exact specifications, making snap gauges a vital tool in this sector.

4. Electronics Manufacturing In the production of electronic components, snap gauges assist in ensuring that parts like connectors, capacitors, and resistors are produced to the correct dimensions, which can significantly affect overall functionality and reliability.

Advantages of Using Snap Gauge Sets

One of the primary advantages of snap gauge sets is their speed and efficiency. They are relatively easy to use, allowing operators to conduct measurements quickly without the need for extensive training. Snap gauges also provide immediate, unambiguous feedback, making it simpler to identify whether a part meets the required specifications.

Moreover, because snap gauges are designed for specific dimensions, they help eliminate human error associated with manual measurements. This can enhance overall productivity by reducing the need for rework and lowering the risk of quality issues later in the production process.

Lastly, snap gauges are built to withstand the rigors of industrial environments. They are made from durable materials that provide long-lasting performance, ensuring that manufacturers can depend on them for accurate measurements for years.

Conclusion

In conclusion, snap gauge sets are essential tools in the manufacturing and engineering industries. Their ability to provide quick, accurate measurements makes them indispensable in quality control processes and various applications where precision is crucial. As industries continue to evolve and demand higher standards in manufacturing, the role of snap gauges will undoubtedly remain significant. By facilitating the accurate measurement of parts, snap gauge sets contribute not only to efficiency and productivity but also to the overall success of manufacturing operations.

-

Thread Plug Gauge Our Promise of Measurement ExcellenceNewsAug.22,2025

-

Gauge Pin Class Reflecting Quality LegacyNewsAug.22,2025

-

Check Valve Types for High Rise BuildingsNewsAug.22,2025

-

Water Control Valve for Irrigation SystemsNewsAug.22,2025

-

Gate Valve with Soft Seal TechnologyNewsAug.22,2025

-

Y Type Strainer for Oil and Gas ApplicationsNewsAug.22,2025

Related PRODUCTS