Nov . 18, 2024 21:27 Back to list

Compact Surface Plate for Precision Measurement and Quality Control Testing

Understanding the Importance of Small Surface Plates in Precision Engineering

In the realm of precision engineering and manufacturing, the small surface plate is an integral tool that serves various vital functions. Often overlooked due to its seemingly mundane appearance, this piece of equipment plays a pivotal role in ensuring accuracy and consistency in the measurement of dimensions. This article delves into the significance of small surface plates, their applications, materials, and impact on precision work.

Definition and Purpose

A small surface plate is essentially a flat, solid plate made from materials that promote stability and rigidity. These plates are typically used as reference planes against which measurements are made, providing a reliable foundation upon which intricate parts can be aligned, inspected, and machined. The reliability and flatness of the plate are crucial; it must be as level as possible to guarantee precise measurements.

The primary purpose of a small surface plate is to aid in the measurement process. It serves to eliminate any variability associated with the surface on which a part might traditionally be placed. By using a small surface plate, engineers and operators can ensure that they are measuring from a uniform reference point. This is essential in fields that require strict adherence to tolerances, such as aerospace, automotive, and medical device manufacturing.

Materials Used

Small surface plates are produced from various materials, each chosen to meet specific application requirements

. The most common materials include granite, cast iron, and composite materials.1. Granite This is one of the most popular materials for surface plates. Granite is chosen for its exceptional rigidity, low thermal expansion, and natural ability to resist wear. Furthermore, it provides a high level of accuracy due to its inherent stability, making it ideal for both heavy and delicate parts.

2. Cast Iron Cast iron surface plates are another option, particularly in industrial settings. They offer similar stability to granite but are often heavier, making them suitable for applications where robust durability is necessary. Cast iron plates can be machined to create very flat surfaces, although they may require periodic resurfacing over time.

3. Composite Materials Emerging technologies have led to the use of specialized composite materials that combine lightweight options with high strength. These materials can provide excellent flatness while being easier to transport and handle than traditional stone or metal plates.

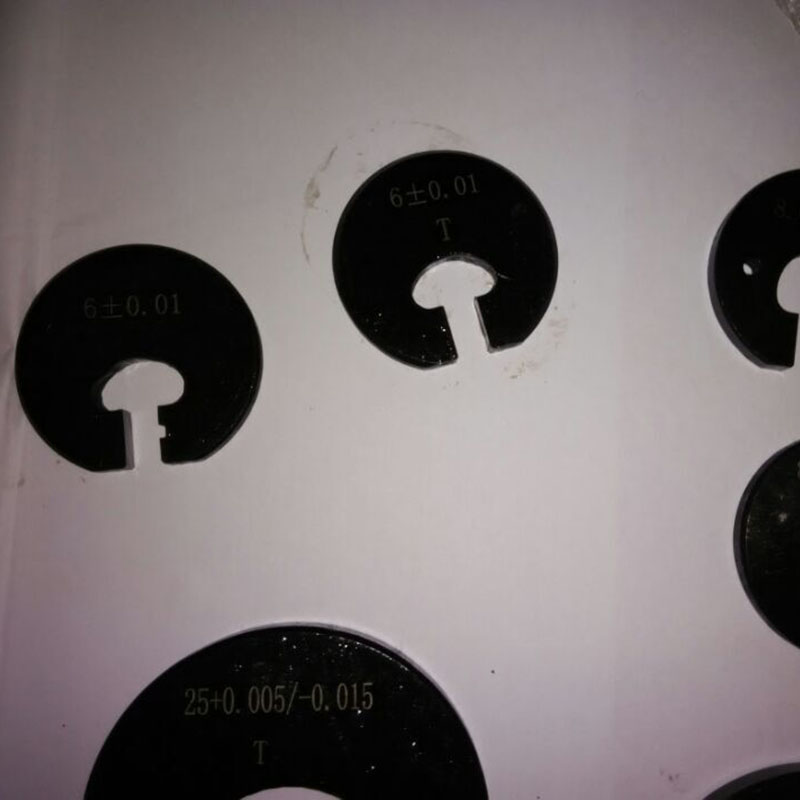

small surface plate

Applications

The applications of small surface plates are numerous and diverse. They are widely used in

- Quality Control Surface plates serve as primary inspection tools for verifying dimensions and tolerances in manufacturing processes. They allow for the precise placement of gauges, calipers, and other measuring tools.

- Layout Work In fabrication shops, surface plates provide a stable platform for laying out parts before machining. This helps in maintaining accuracy during the design phase.

- Assembly In assembly operations, small surface plates provide a level working surface that is essential for aligning components correctly before fastening them together.

- Machining During machining operations, small surface plates assist in setting up workpieces to ensure that they are held at the proper angle and orientation for accurate machining.

Conclusion

The importance of small surface plates in precision engineering cannot be overstated. They form the backbone of quality assurance and control processes, ensuring that the components manufactured meet the necessary specifications and tolerances. By serving as a reliable reference point, small surface plates enable engineers, machinists, and quality control inspectors to carry out their work with confidence.

As technology advances and manufacturing techniques evolve, the design and materials used in small surface plates may continue to improve, allowing for even greater precision and versatility. For anyone involved in precision machining or engineering, a thorough understanding of the role of small surface plates and their applications is essential for achieving excellence in their craft. Investing in high-quality surface plates is not merely an option; it’s a necessity for those who strive to maintain the highest standards in their work.

-

Thread Plug Gauge Our Promise of Measurement ExcellenceNewsAug.22,2025

-

Gauge Pin Class Reflecting Quality LegacyNewsAug.22,2025

-

Check Valve Types for High Rise BuildingsNewsAug.22,2025

-

Water Control Valve for Irrigation SystemsNewsAug.22,2025

-

Gate Valve with Soft Seal TechnologyNewsAug.22,2025

-

Y Type Strainer for Oil and Gas ApplicationsNewsAug.22,2025

Related PRODUCTS