Nov . 30, 2024 01:07 Back to list

Understanding No-Go Pin Gauge for Precision Measurement in Manufacturing

Understanding No-Go Pin Gauges A Key Tool in Quality Control

In the realm of manufacturing and quality control, precision is paramount. Ensuring that parts and components meet strict specifications requires a range of measurement tools, one of which is the no-go pin gauge. This device plays a crucial role in assessing whether a component adheres to predefined tolerances during the production process.

Understanding No-Go Pin Gauges A Key Tool in Quality Control

No-go pin gauges are often used in conjunction with go gauges, creating a two-part system for ensuring the proper dimensions of components. The go gauge tests whether a feature is large enough while the no-go gauge checks if it is too large. This dual approach enables manufacturers to maintain precise control over the production process, minimizing the risk of defects and facilitating compliance with industry standards.

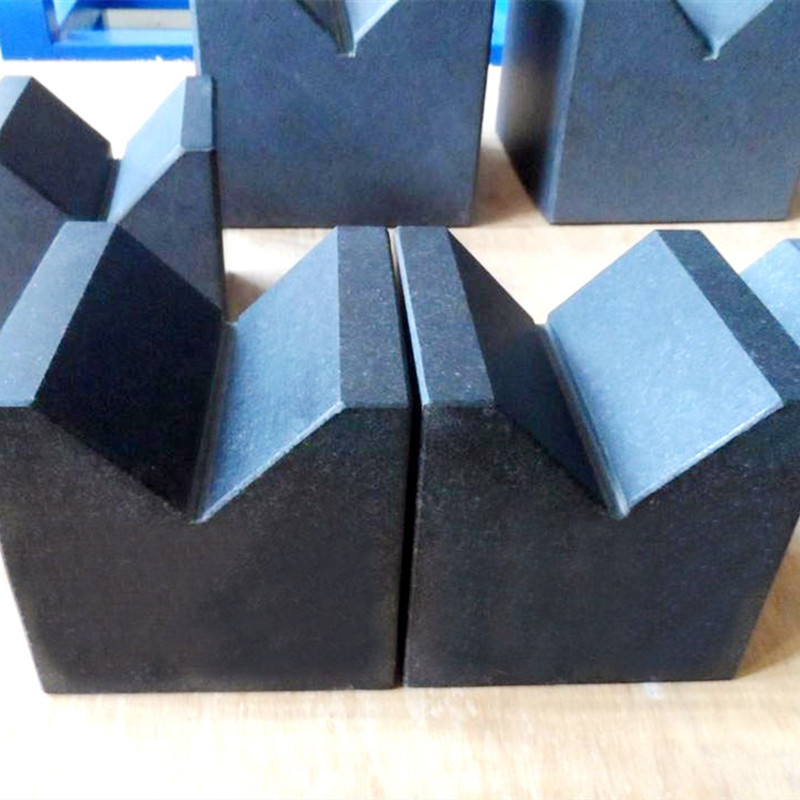

no go pin gauge

One of the primary advantages of using no-go pin gauges is their ability to quickly identify defects in production. This not only saves time during the inspection process but also helps to reduce costs associated with excessive rework or scrap. By utilizing these tools, manufacturers can significantly improve their efficiency and productivity.

Moreover, no-go pin gauges are applicable across various industries, including automotive, aerospace, and general engineering. They can be custom-made to suit specific requirements, ensuring that they fit the unique specifications of different components. This versatility makes no-go gauges invaluable not only for quality assurance but also for ensuring that manufacturing processes meet regulatory requirements.

In conclusion, no-go pin gauges are essential tools in the arsenal of quality control measures. Their simplicity, effectiveness, and adaptability make them crucial for ensuring that manufactured parts meet stringent standards, thereby enhancing overall product quality and reliability. Investing in good-quality gauging tools like no-go pin gauges is a step toward achieving excellence in manufacturing processes.

-

Thread Plug Gauge Our Promise of Measurement ExcellenceNewsAug.22,2025

-

Gauge Pin Class Reflecting Quality LegacyNewsAug.22,2025

-

Check Valve Types for High Rise BuildingsNewsAug.22,2025

-

Water Control Valve for Irrigation SystemsNewsAug.22,2025

-

Gate Valve with Soft Seal TechnologyNewsAug.22,2025

-

Y Type Strainer for Oil and Gas ApplicationsNewsAug.22,2025

Related PRODUCTS