Jul . 04, 2025 09:22 Buyela kuluhlu

Features of Welding Table Cast Iron

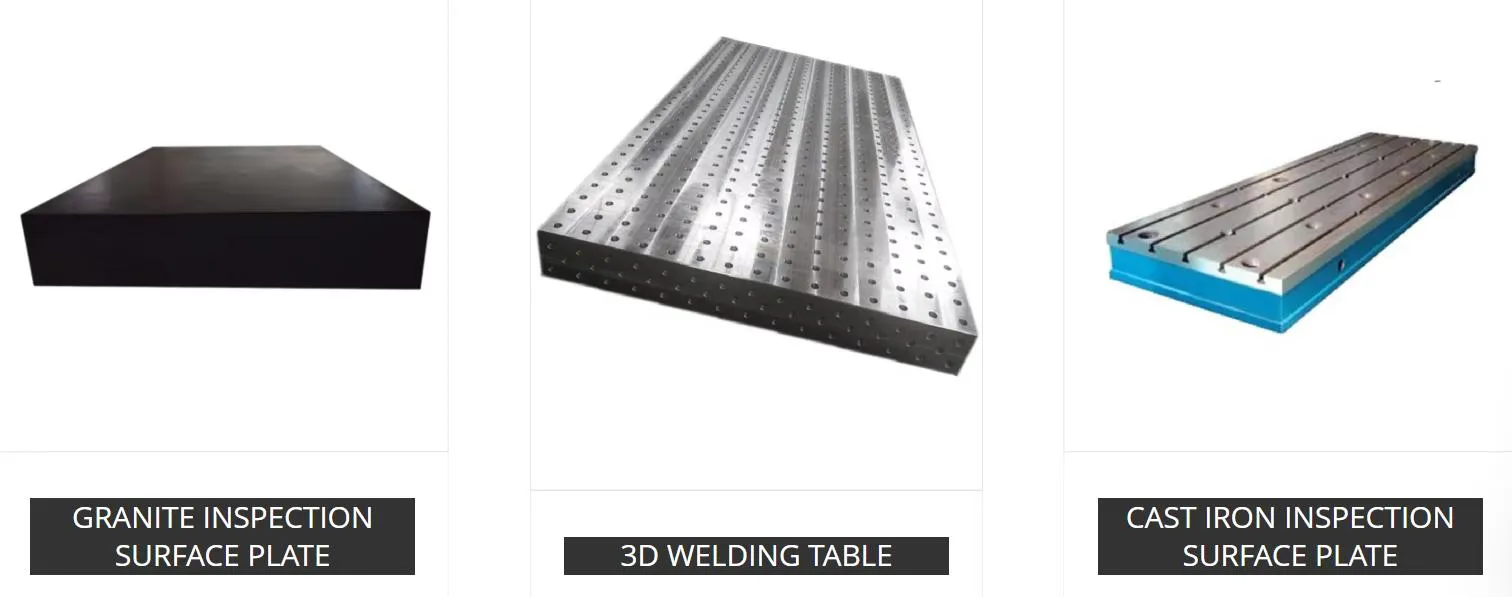

Professional welders require durable work surfaces, making strong welding table products essential workshop equipment. The welding table cast iron offers superior performance compared to other materials, while specialized welding table tools enhance functionality. This guide explores the key characteristics that make cast iron welding tables ideal for industrial and workshop applications.

Material Advantages of Welding Table Cast Iron

- Exceptional heat resistance makes strong welding table surfaces ideal for high-temperature work

• Natural vibration damping properties of welding table cast iron improve weld quality

• High-density composition prevents warping in premium welding table tools

• Excellent thermal mass maintains stable temperatures in strong welding table surfaces

• Long-term dimensional stability of welding table cast iron ensures lasting accuracy

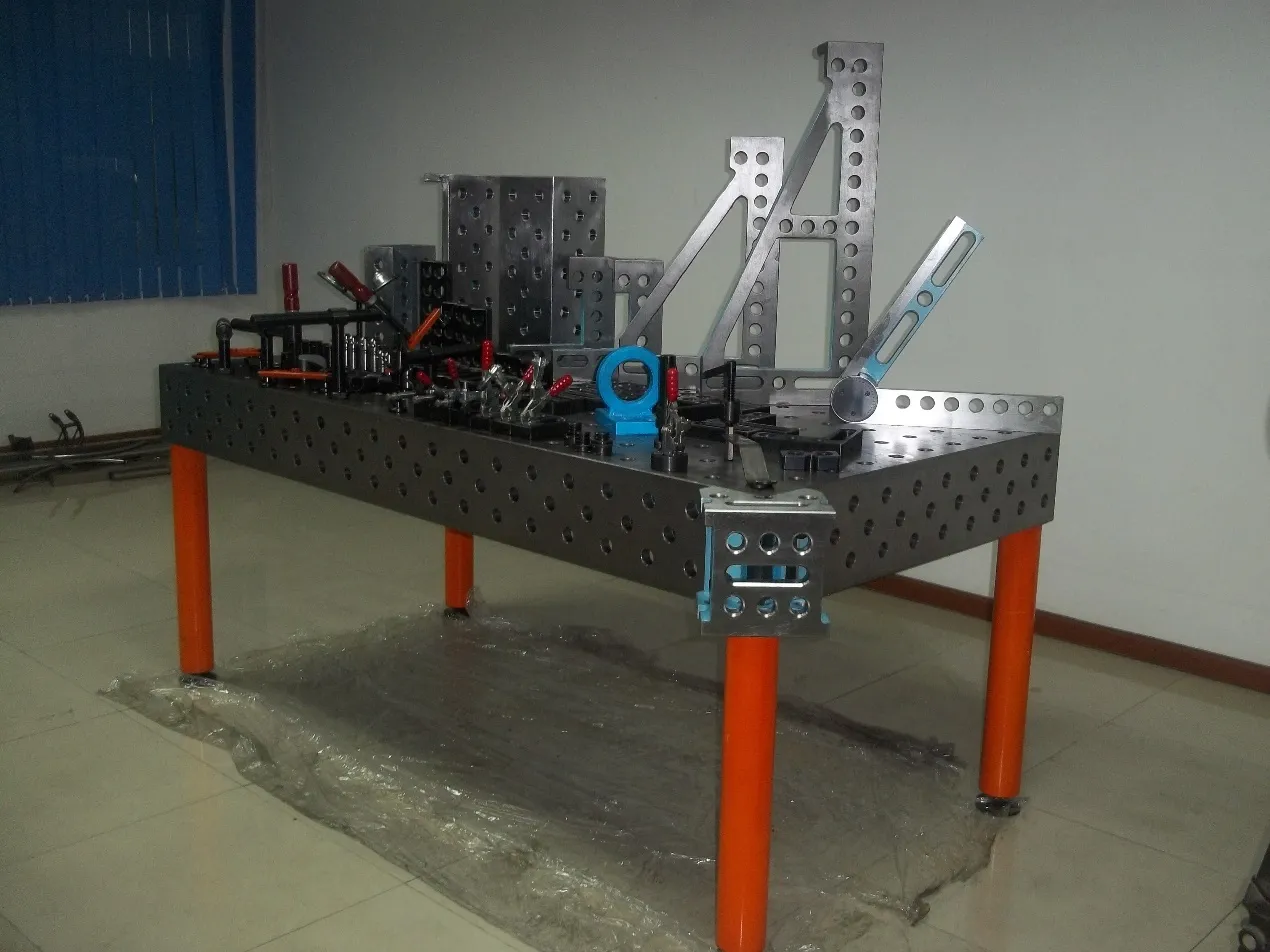

Structural Features of Strong Welding Table

- Reinforced frame designs support heavy workloads on welding table cast ironmodels

• Precision-machined surfaces ensure flatness across welding table toolswork areas

• Modular designs allow expansion of strong welding table configurations

• Integrated clamping systems complement welding table cast iron functionality

• Customizable thickness options for different welding table tools applications

Functional Benefits of Welding Table Tools

- Compatible fixture systems enhance strong welding tableversatility

• Magnetic hold-down accessories secure workpieces to welding table cast ironsurfaces

• Adjustable height mechanisms on premium welding table tools

• Integrated measuring systems for precision on strong welding table models

• Quick-change components expand welding table cast iron capabilities

Industrial Applications for Welding Table Cast Iron

- Heavy fabrication work requiring strong welding tablestability

• Precision welding applications using welding table toolsaccessories

• Training workshops utilizing durable welding table cast iron surfaces

• Production line stations with customized strong welding table setups

• Repair and maintenance operations needing versatile welding table tools

Maintenance Requirements for Strong Welding Table

- Regular cleaning prevents buildup on welding table cast ironsurfaces

• Periodic inspection of welding table toolscomponents and accessories

• Surface conditioning maintains strong welding table flatness over time

• Proper storage of welding table cast iron when not in use

• Lubrication of moving parts in advanced welding table tools systems

Strong Welding Table FAQS

Q: How does a strong welding table enhance durability compared to a standard table when using welding table tools?

A: A strong welding table is built with heavy-gauge steel or cast iron, capable of withstanding high heat and impact from welding torches, grinders, or clamps. Unlike flimsy tables, its reinforced frame and thick top (often 10–20mm) prevent warping, while integrated slots or holes for welding table tools (like clamps or magnetic fixtures) ensure secure positioning without damaging the surface.

Q: What advantages do welding table cast iron surfaces offer for heavy-duty welding?

A: Welding table cast iron surfaces excel in heat resistance, absorbing sparks and distributing thermal stress without cracking. Their high mass reduces vibration during welding, improving precision for tasks like metal fabrication. Additionally, cast iron’s inherent flatness (often ground to 0.1mm/m tolerance) provides a stable base for welding table tools, ensuring accurate part alignment.

Q: Can welding table tools be customized for a strong welding table?

A: Yes. Many strong welding tables feature modular T-slots or grid patterns, allowing customization with welding table tools like angle plates, vise mounts, or adjustable stops. For example, magnetic welding clamps can be positioned along slots to hold complex shapes, while height-adjustable supports cater to varied workpiece sizes—essential for custom fabrication projects.

Q: How should I maintain a strong welding table with welding table cast iron surfaces?

A: After use, clean the welding table cast iron surface with a wire brush to remove slag or spatter. Apply a thin layer of anti-rust oil to prevent corrosion, especially in humid environments. For welding table tools like clamps or gauges, inspect moving parts for wear and lubricate hinges regularly to ensure smooth operation. Avoid dropping heavy tools on the table, as impacts can dent cast iron surfaces.

Q: What safety considerations apply when using welding table tools on a strong welding table?

A: Always secure welding table tools (e.g., clamps or fixturing) tightly to prevent workpiece movement during welding, which can cause injuries or faulty welds. Ensure the strong welding table is grounded to dissipate static electricity, and never place flammable materials near the work area. For heavy tools like grinders, use anti-vibration pads to reduce strain on the table and minimize noise exposure.

Welcome to Storaen Machinery,Step into the world of Storaen (Cangzhou) International Trading Co., your trusted partner from Botou, China – a global hub of precision manufacturing. At www.strmachinery.com , we blend decades of expertise with cutting-edge innovation, crafting top-tier cast iron welding platforms, measuring tools, and valves that redefine industrial reliability.

Our roots in Botou’s casting legacy fuel unmatched quality, while a relentless drive for innovation ensures we stay ahead of industry trends. Committed to sustainability and customer success, we don’t just build products – we forge partnerships. Whether you’re engineering the future or perfecting precision, let Storaen’s legacy of excellence power your next project. Welcome to a world where quality meets ambition – let’s build greatness together.

-

Flanged Gate Valve: A Reliable Choice for Industrial and Municipal SystemsIindabaAug.20,2025

-

Soft Seal Gate Valve: A Modern Solution for Reliable Pipeline ControlIindabaAug.20,2025

-

Gate Valve Types: Understanding the Options for Your Pipeline SystemsIindabaAug.20,2025

-

Y Type Strainer: Essential for Clean and Efficient Flow SystemsIindabaAug.20,2025

-

Cast Iron Y Strainer: Durable Solutions for Demanding ApplicationsIindabaAug.20,2025

-

Flanged Y Strainer: An Essential Component in Industrial Filtration SystemsIindabaAug.20,2025

Iimveliso ezinxulumeneyo