Th11 . 11, 2024 11:09 Back to list

tilting disc check valve

Understanding the Tilting Disc Check Valve

A tilting disc check valve is an essential component in many fluid control systems. This type of valve is designed to prevent backflow, ensuring that fluid flows in only one direction. Its unique design features a disc that tilts on a pivot, allowing it to open for the forward flow of fluid and close tightly to prevent reverse flow. In this article, we will explore the working principle, applications, advantages, and maintenance of tilting disc check valves.

Working Principle

The tilting disc check valve consists of a circular disc or flap that is mounted on a hinge. When fluid enters the valve in the forward direction, the flow forces the disc to tilt away from the seat, allowing the fluid to pass through. The angle of the disc can vary, but typically it tilts to an angle of 45 degrees or more, which enables smooth flow. Once the pressure of the incoming fluid drops or if there is a reverse flow, the disc tilts back due to the gravitational force and the hydraulic pressure, seating itself against the valve body. This action creates a tight seal that prevents any backflow, protecting the system from potential damages.

Applications

Tilting disc check valves are widely used across various industries. They are favored in water treatment facilities, oil and gas pipelines, power plants, and many industrial applications where fluids must flow in one direction. Due to their robust design and reliable operation, they are particularly effective in high-pressure systems. Additionally, these valves can handle a variety of media, including water, oil, and chemicals, making them versatile components in fluid systems.

In power generation, for instance, tilting disc check valves are vital in cooling water systems to prevent backflow that could disrupt operations

. In fire protection systems, they ensure that water flows to the hydrant or sprinkler system when needed while preventing any reverse flow that might compromise the system's integrity.tilting disc check valve

Advantages

One of the primary benefits of tilting disc check valves is their efficiency in preventing backflow. Unlike traditional swing check valves, which may not close quickly enough in certain conditions, tilting disc check valves provide a more decisive sealing action. This capability significantly reduces the risk of water hammer—a dangerous pressure surge that can occur in pipelines when the flow suddenly changes direction.

Moreover, the streamlined design of tilting disc check valves minimizes pressure drop across the valve, which is crucial for maintaining system efficiency. They typically require less space than other types of check valves, allowing for easier installation in confined areas. Their lightweight design also contributes to ease of handling during installation and maintenance.

Maintenance

Maintaining a tilting disc check valve is essential for ensuring its long-term performance. Regular inspections should include checking the disc for signs of wear or damage, ensuring that it swings freely on its pivot without any obstruction. Accumulation of debris or corrosion within the valve body can hinder the disc's movement, so cleaning should be performed as needed.

Additionally, it is crucial to check the sealing surfaces for any irregularities. A damaged or worn seat can lead to leaks and ineffective backflow prevention. If necessary, components should be replaced promptly to prevent operational issues.

In conclusion, the tilting disc check valve is a reliable solution for controlling fluid flow in a variety of applications. Its design allows for effective prevention of backflow while maintaining system efficiency. With proper maintenance, these valves can serve effectively over extended periods, making them a staple in fluid control systems. As industries continue to evolve, the importance of choosing the right check valve, like the tilting disc design, will only grow, ensuring operational integrity and safety in fluid management systems.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

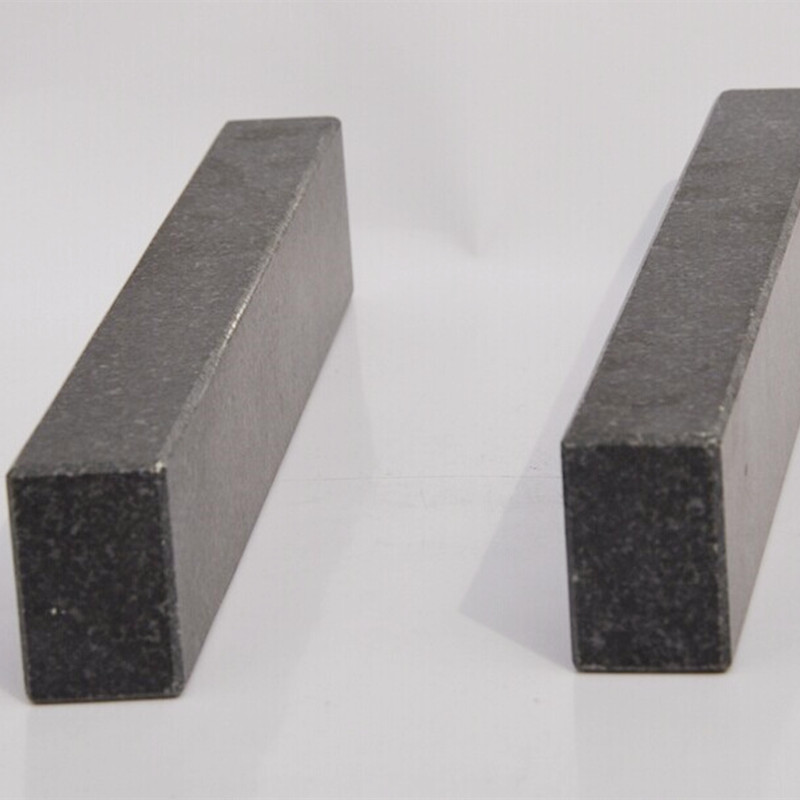

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS