Th9 . 15, 2024 21:01 Back to list

Snap Gauge Micrometer - Precision Measurement Tool

Exploring the Snap Gauge Micrometer A Precision Measurement Tool

The world of precision engineering relies heavily on accurate measurements, and one of the unsung heroes in this domain is the snap gauge micrometer. This innovative tool combines the straightforwardness of a basic gauge with the precision of a micrometer, making it essential for various applications across manufacturing and quality control processes.

At its core, a snap gauge micrometer is designed to measure the external dimensions of an object with remarkable accuracy. Unlike traditional calipers that can be prone to read errors, snap gauges have a fixed measuring point that allows for consistent and repeatable results. The snap gauge typically consists of two parallel measuring faces set a specific distance apart, which can be adjusted or fixed depending on the design. This feature ensures precision measurements within a defined tolerance range.

One of the main advantages of snap gauge micrometers is their ease of use. Operators can take measurements quickly, making them ideal for high-volume production environments where efficiency is crucial. The design of a snap gauge allows it to 'snap' onto the workpiece, providing a clear indication of whether the item is within specified tolerances without the need for extensive calibration or setup. This can significantly reduce the likelihood of human error in measurement and improve overall productivity in a manufacturing workflow.

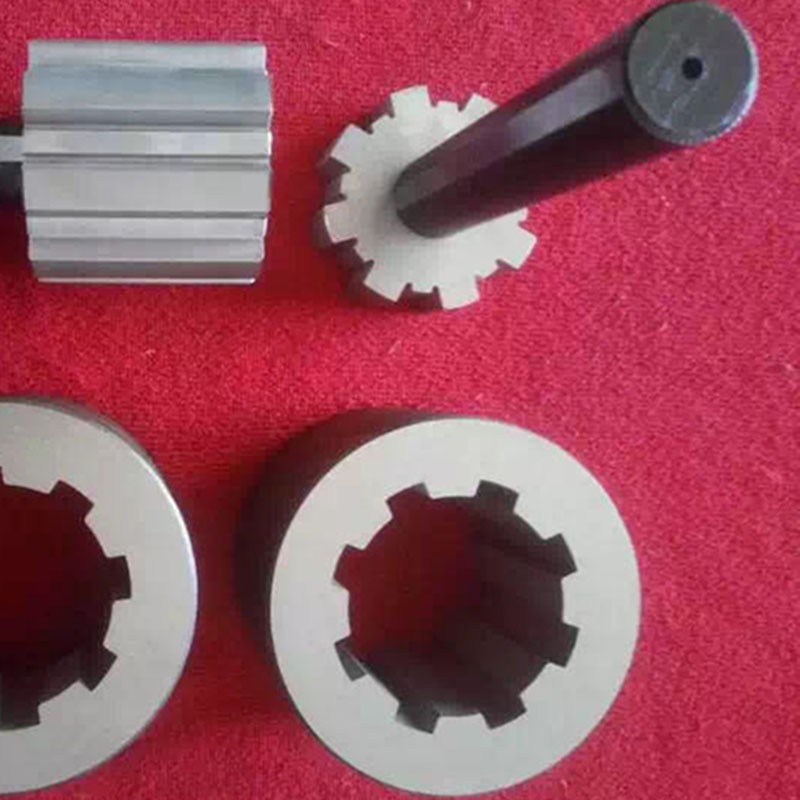

snap gauge micrometer

The material of the snap gauge micrometer also plays a vital role in its functionality. Typically crafted from high-quality steel or stainless steel, these tools are designed to resist wear, corrosion, and environmental factors that could impact their accuracy. Some models even come with a wear-resistant coating to enhance durability, ensuring that they can withstand the rigors of daily use in various industrial settings.

Another noteworthy aspect of snap gauge micrometers is their versatility. They can be used for a wide range of applications, including measuring diameters, thicknesses, and even the depth of slots or grooves. This flexibility makes them an invaluable tool for engineers and quality control inspectors who constantly need to measure different components in their work.

In addition to their practical applications, combining a snap gauge with digital readouts can further enhance their precision and ease of use. Digital snap gauges provide operators with immediate and clear measurement readings, minimizing the chance of misinterpretation and streamlining the inspection process.

In summary, snap gauge micrometers represent a critical tool in the arsenal of precision measurement devices. Their combination of accuracy, simplicity, and versatility makes them ideal for a wide range of manufacturing applications. By employing snap gauge micrometers in quality control processes, organizations can ensure that they maintain high standards for product specifications, ultimately leading to better products and increased customer satisfaction. In the evolving landscape of manufacturing, embracing tools that enhance accuracy and efficiency, like the snap gauge micrometer, remains a key strategy for success.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS