Th6 . 25, 2025 09:29 Trở lại danh sách

Role of Snap Ring Gages in Aerospace Quality Control

The aerospace industry operates under stringent quality control standards to ensure the safety, reliability, and performance of aircraft components. Even the slightest deviation in part dimensions can lead to catastrophic failures, making precision measurement tools indispensable. Among these tools, snap ring gage, steel ring gauge, standard ring gauge, and gauge meant ring play pivotal roles in verifying the conformity of critical components. This article explores how these specialized instruments contribute to aerospace quality assurance, emphasizing their design, applications, and importance in maintaining industrial compliance.

Precision Measurement with Snap Ring Gage in Aerospace Components

A snap ring gage is a go/no-go gauge designed to measure the internal or external diameters of grooves, snap rings, and retaining rings. In aerospace manufacturing, these components secure bearings, shafts, and other rotating parts, ensuring they remain fixed under extreme operational stresses. The snap ring gage validates whether the groove dimensions fall within acceptable tolerances, preventing assembly errors that could compromise structural integrity.

Aerospace applications demand gages with minimal thermal expansion and high wear resistance. Manufacturers often use hardened steel or carbide-tipped snap ring gage designs to withstand repetitive use in high-volume production environments. For instance, turbine engine assemblies require snap rings to hold blade assemblies in place, and a miscalibrated gage could result in improper seating, leading to engine failure. By integrating snap ring gage systems into automated inspection lines, aerospace suppliers achieve rapid, repeatable measurements while adhering to AS9100 quality management standards.

Steel Ring Gauge: Durability for High-Stress Environments

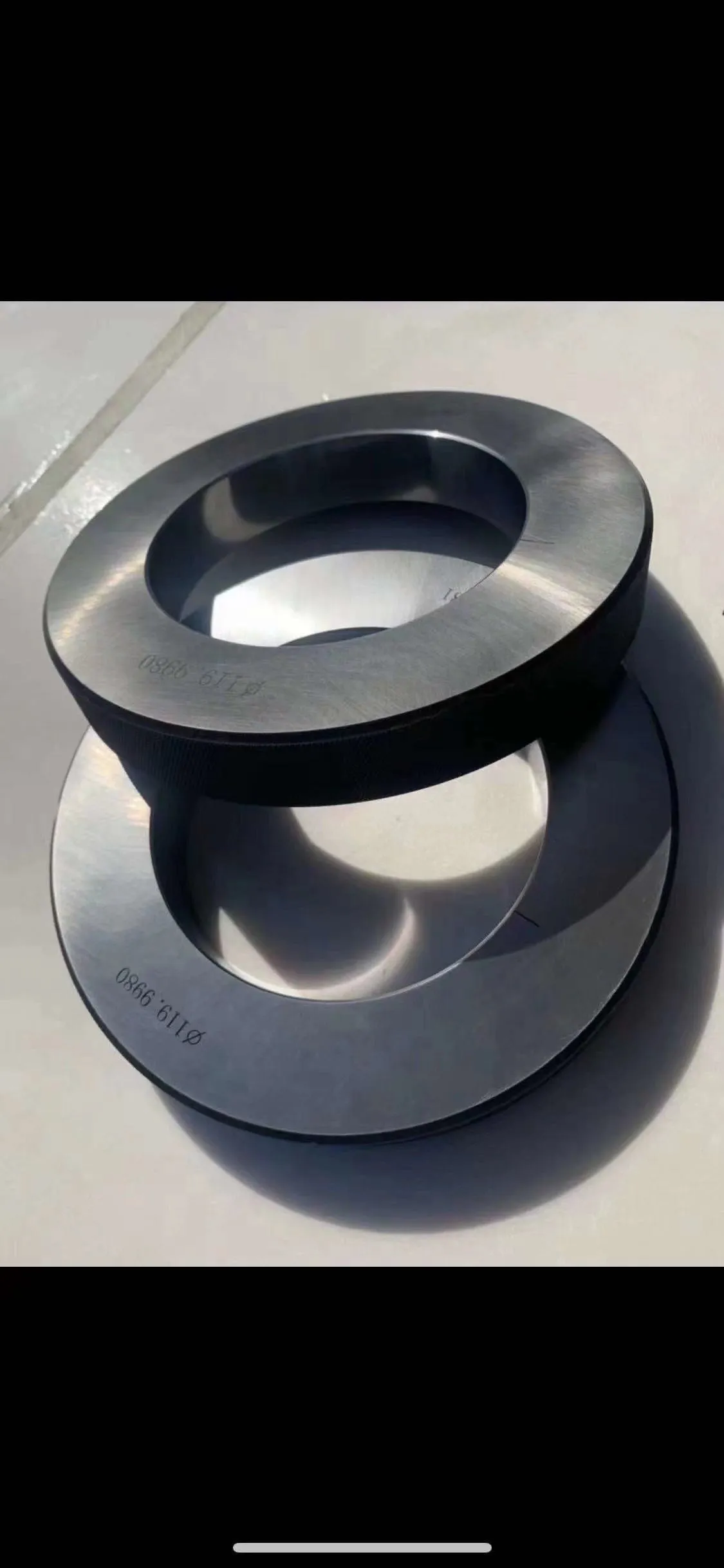

The steel ring gauge is a cornerstone of dimensional inspection in aerospace due to its robustness and longevity. Crafted from high-grade tool steel or stainless steel, these gages resist deformation, corrosion, and wear—critical traits for environments exposed to temperature fluctuations, hydraulic fluids, and mechanical stress.

In landing gear manufacturing, for example, steel ring gauge tools verify the inner diameters of axle housings. These components must align perfectly with wheel bearings to avoid uneven load distribution during takeoff and landing. A steel ring gauge ensures that each housing meets precise specifications, reducing the risk of premature wear. Additionally, the magnetic properties of certain steel alloys allow for integration with automated sorting systems, streamlining quality control workflows in large-scale production facilities.

Standard Ring Gauge: Ensuring Universal Compliance in Aerospace

A standard ring gauge serves as a master reference for calibrating other measurement devices, such as micrometers and bore gauges. Traceable to national or international standards like NIST (National Institute of Standards and Technology), these gages guarantee that all inspection tools within a production line adhere to unified accuracy benchmarks.

Aerospace manufacturers rely on standard ring gauge sets to maintain consistency across global supply chains. For instance, a turbine disk sourced from one supplier must seamlessly integrate with a shaft produced elsewhere. By calibrating inspection tools using a common standard ring gauge, companies eliminate dimensional discrepancies that could delay assembly or necessitate rework. Furthermore, regular audits using these gages help aerospace firms comply with FAA and EASA regulations, which mandate rigorous documentation of measurement traceability.

FAQs About Gauge Meant Ring in Aerospace Applications

What is the primary function of a gauge meant ring in quality control?

A gauge meant ring is a specialized tool used to verify the dimensional accuracy of cylindrical parts, such as engine pistons or hydraulic cylinders. It ensures that components meet predefined tolerances before they are approved for assembly.

How does a steel ring gauge differ from a carbide gauge?

A steel ring gauge is typically more cost-effective and suitable for general-purpose inspections, while carbide gauges offer superior hardness for high-wear applications. Both are vital in aerospace, but material choice depends on the inspection frequency and environmental conditions.

Can a standard ring gauge be used to calibrate a snap ring gage?

Yes. Master standard ring gauge sets are often used to calibrate snap ring gage tools, ensuring their measurements remain traceable to international standards.

Why is material choice critical for a gauge meant ring?

Aerospace components operate in extreme conditions, so the gauge meant ring must resist thermal expansion, corrosion, and mechanical wear to maintain measurement accuracy over time.

How often should a steel ring gauge be recalibrated?

Recalibration intervals depend on usage frequency, but aerospace manufacturers typically recalibrate steel ring gauge tools every 6–12 months to comply with quality management protocols.

In aerospace quality control, precision measurement tools like the snap ring gage, steel ring gauge, standard ring gauge, and gauge meant ring are non-negotiable for ensuring component reliability. These instruments enable manufacturers to uphold tolerances measured in microns, mitigate risks of in-flight failures, and meet rigorous regulatory demands. As aerospace systems grow more complex, the role of these gages will only expand, solidifying their status as indispensable assets in the pursuit of aviation excellence.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlTin tứcAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseTin tứcAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsTin tứcAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesTin tứcAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingTin tứcAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlTin tứcAug.05,2025

Những sảm phẩm tương tự