Th12 . 05, 2024 13:25 Back to list

Understanding the Function and Importance of Plumbing Check Valves in Systems

Understanding Plumbing Check Valves Importance, Types, and Installation Tips

In any plumbing system, ensuring a smooth flow of water is essential for both residential and commercial properties. However, to maintain this flow and prevent potential backflow issues, plumbing check valves play a pivotal role. This article delves into what check valves are, their importance in plumbing systems, the different types available, and tips for proper installation.

What is a Check Valve?

A check valve, also known as a non-return valve or one-way valve, is a device that permits fluid (liquid or gas) to flow in only one direction. This one-way operation prevents backflow, which can lead to contamination, damage to pumps, and a myriad of issues in plumbing systems. Check valves are crucial components found in various systems, including residential plumbing, industrial applications, and municipal water supply networks.

Importance of Check Valves

1. Preventing Backflow The primary function of a check valve is to prevent backflow, which occurs when water flows in the opposite direction. This can lead to sewage contamination in potable water systems or damage to pumps and pipelines.

2. Protecting Equipment Check valves help protect pumps and other equipment from potential reverse flow that might cause operational failures or damage due to hydraulic forces.

3. Maintaining Pressure In plumbing systems, consistent pressure is vital. Check valves help maintain the correct pressure by preventing the reverse flow of water, ensuring the efficiency and efficacy of the entire system.

4. Simplicity and Reliability Check valves are designed to operate automatically without any external control. Their simple design allows for reliable operation, minimizing maintenance needs.

Types of Check Valves

Check valves come in various types, each designed for specific applications

. Here are a few common types1. Swing Check Valve This type uses a hinged disc to allow fluid to flow in one direction while swinging closed to block reverse flow. It is most commonly used in larger pipelines and applications where the flow rate is high.

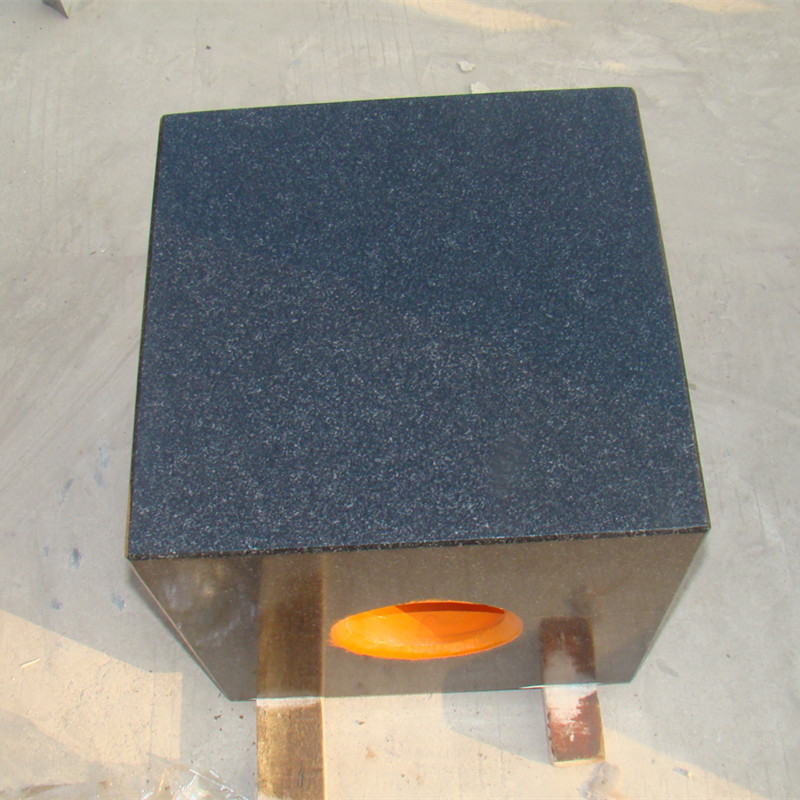

plumbing check valve

2. Lift Check Valve Utilizing a disc that moves up and down, lift check valves allow flow in one direction while lifting the disc from its seat. They are effective at low flow rates and are often installed in vertical piping systems.

3. Ball Check Valve Featuring a spherical ball that seats against a valve opening, these valves prevent backflow by simply blocking the reverse flow path. They are compact and suitable for high-pressure applications.

4. Diaphragm Check Valve In this design, a flexible diaphragm moves to open and close the valve based on the pressure differential. This type is often used in applications requiring high sensitivity, such as in chemical processes.

Installation Tips for Check Valves

When installing check valves, several factors must be considered to ensure their effectiveness

1. Proper Orientation Ensure the check valve is installed in the correct orientation as indicated by the flow direction arrows on the body. Incorrect installation can lead to valve malfunction.

2. Suitable Size Select a valve that matches the pipe diameter to avoid pressure drop issues and ensure optimal performance.

3. Testing After installation, test the system to ensure that the check valve is working correctly and that there are no leaks.

4. Maintenance While check valves generally require minimal maintenance, periodic checks can help detect wear or damage, ensuring reliable operation.

Conclusion

In summary, plumbing check valves are vital components that contribute to the efficiency and safety of plumbing systems. By preventing backflow, protecting equipment, maintaining pressure, and offering simple reliability, they serve an essential function in various applications. Understanding the types of check valves and following proper installation practices can ensure a well-functioning plumbing system, safeguarding against potential issues that could arise from improper water flow. Whether for home plumbing or industrial applications, investing in quality check valves is a decision that pays off in the long run.

-

thread-plug-gauge-our-promise-of-measurement-excellenceNewsAug.22,2025

-

gauge-pin-class-reflecting-quality-legacyNewsAug.22,2025

-

check-valve-types-for-high-rise-buildingsNewsAug.22,2025

-

water-control-valve-for-irrigation-systemsNewsAug.22,2025

-

gate-valve-with-soft-seal-technologyNewsAug.22,2025

-

y-type-strainer-for-oil-and-gas-applicationsNewsAug.22,2025

Related PRODUCTS