Th12 . 03, 2024 17:41 Back to list

ductile iron knife gate valve

The Ductile Iron Knife Gate Valve A Versatile Solution for Fluid Control

In the world of fluid management and control systems, the knife gate valve has emerged as an essential component, particularly in demanding industrial applications. Among the various materials used in their construction, ductile iron stands out as a preferred choice, providing a robust solution for handling a diverse range of media, from water and wastewater to slurries and other viscous materials.

What is a Knife Gate Valve?

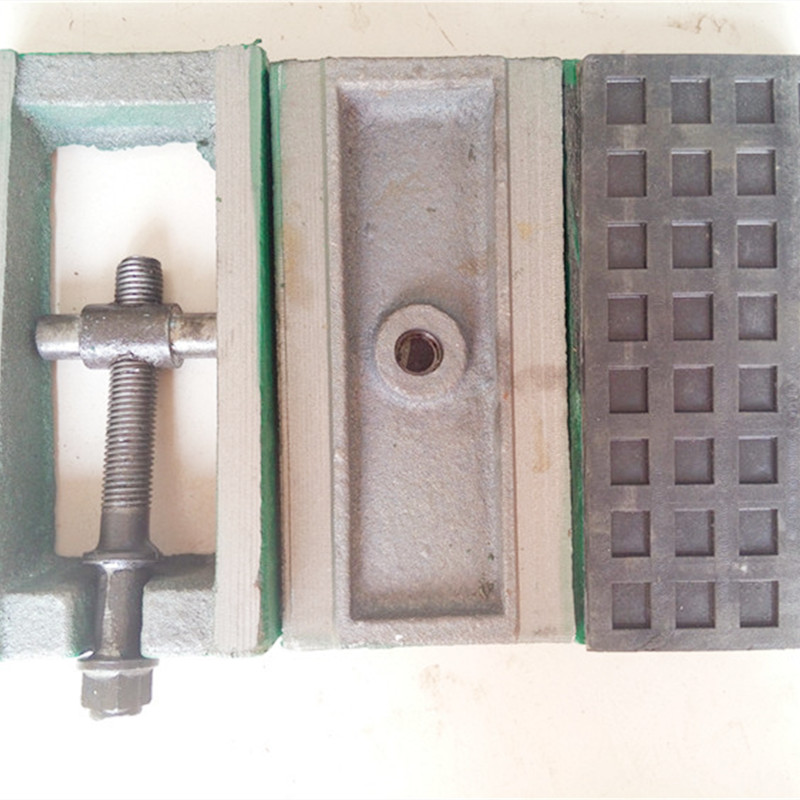

A knife gate valve is specifically designed to control the flow of liquids and slurries in a pipeline. It features a sharp-edged gate that slides down through the seat to either block or allow the flow. This design is particularly effective in applications where a complete shut-off is required, and it is well-suited for handling bulk materials or viscous fluids. The simplicity of its design, combined with its ability to handle a wide range of pressures, makes it an ideal choice for many industries, including water treatment, mining, food processing, and chemical manufacturing.

The Benefits of Ductile Iron

Ductile iron, also known as spheroidal graphite iron, is an alloy that has gained popularity in various industries due to its excellent mechanical properties. It offers high tensile strength and ductility, meaning it can withstand considerable stress without breaking. This is particularly advantageous in the manufacturing of knife gate valves, as they are often subjected to high pressures and demanding service conditions.

One of the primary benefits of ductile iron is its resistance to corrosion and impact. This characteristic is critical in environments where valves are exposed to abrasive media or harsh chemicals. The longevity of ductile iron knife gate valves can significantly reduce maintenance costs and downtime, making them a cost-effective choice in the long run.

ductile iron knife gate valve

Applications in Various Industries

Ductile iron knife gate valves are widely used across several sectors. In the water and wastewater treatment industry, for instance, these valves help manage the flow of sewage and sludge, ensuring efficient processing and treatment. Their ability to handle solids and slurries makes them ideal for applications involving thick liquids, found in mining and mineral processing.

In the food and beverage industry, ductile iron knife gate valves are employed to control the flow of viscous products, such as syrups and purees. Their clean, hygienic construction allows for easy maintenance and sanitation, complying with food safety regulations.

Chemical processing also benefits from the robustness of ductile iron valves. They are capable of handling aggressive chemicals, providing durability and safety in chemical transport systems. The strength and reliability of ductile iron ensure that these valves can operate under high pressure and temperature variations, critical factors in many chemical applications.

Conclusion

The ductile iron knife gate valve represents a fusion of strength, durability, and versatility, making it a vital component in modern industrial fluid control systems. Its ability to effectively manage a wide range of media, from water to slurries and chemicals, highlights the significant role it plays across multiple industries.

As industrial processes become increasingly complex, the demand for reliable and efficient fluid control mechanisms will only grow. Ductile iron knife gate valves, with their superior material properties and design, are well-positioned to meet these challenges, ensuring smooth and safe operation in various applications. Investment in such valves not only translates to enhanced operational efficiency but also contributes to the overall safety and reliability of fluid handling systems. In conclusion, for industries that prioritize durability and performance, ductile iron knife gate valves are a solution that delivers exceptional results.

-

thread-plug-gauge-our-promise-of-measurement-excellenceNewsAug.22,2025

-

gauge-pin-class-reflecting-quality-legacyNewsAug.22,2025

-

check-valve-types-for-high-rise-buildingsNewsAug.22,2025

-

water-control-valve-for-irrigation-systemsNewsAug.22,2025

-

gate-valve-with-soft-seal-technologyNewsAug.22,2025

-

y-type-strainer-for-oil-and-gas-applicationsNewsAug.22,2025

Related PRODUCTS