Dek . 11, 2024 21:22 Back to list

Precision Measuring Tools for Bore Gauging Applications in Engineering and Manufacturing

Understanding the Starrett Bore Gauge Precision Measurement in Mechanical Engineering

In the realm of mechanical engineering and manufacturing, precision is paramount. Whether it's part tolerances, assembly fits, or product dimensions, accurate measurement tools are essential. One such tool that stands out for its reliability and accuracy is the Starrett Bore Gauge. This specialized measuring device plays a critical role in assessing the internal dimensions of holes and cylindrical features, ensuring that parts are manufactured to exact specifications. In this article, we will explore the features, applications, and benefits of using the Starrett Bore Gauge.

What is a Bore Gauge?

A bore gauge is a precision instrument used to measure the internal diameter of holes or tubes. It can determine the size, shape, and form of the internal surfaces, which is crucial in many industrial applications. The Starrett Bore Gauge is designed to deliver accurate readings, even in hard-to-reach areas, making it an essential tool for machinists, quality control inspectors, and maintenance professionals.

Key Features of the Starrett Bore Gauge

1. Accuracy and Precision Starrett is known for its commitment to precision engineering. The bore gauge is designed to provide accurate measurements, often within thousandths of an inch. This level of detail is indispensable when dealing with components that must fit together seamlessly.

2. User-Friendly Design The Starrett Bore Gauge typically features a simple yet robust design, making it easy to use. Many models come with a single or dual measuring rod, allowing for quick adjustments and readings. The ergonomic handle ensures a secure grip, which is particularly beneficial for prolonged use.

3. Multiple Range Options Starrett offers a variety of bore gauges that cater to different measurement ranges. This selection allows users to choose the right tool for their specific applications, ensuring that they can measure small or large bores with ease.

4. Durable Construction Starrett products are known for their durability, and the bore gauge is no exception. Made from high-quality materials, these gauges can withstand the rigors of workshop environments and are built to last, providing value over time.

5. Versatility One of the standout features of the Starrett Bore Gauge is its versatility. It can be used in a wide range of industries, from automotive and aerospace to manufacturing and maintenance. This broad applicability makes it a go-to instrument for many professionals.

Applications of the Starrett Bore Gauge

The versatility of the Starrett Bore Gauge allows it to be utilized in various applications, including

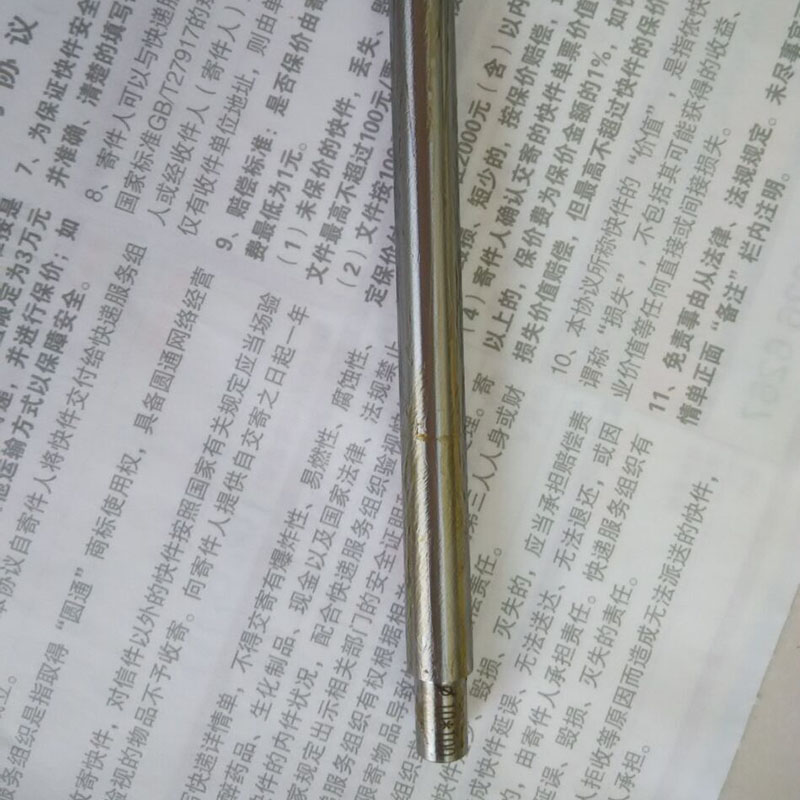

starrett bore gauge

- Quality Control In manufacturing, ensuring that parts meet dimensional specifications is critical. The bore gauge helps quality control inspectors verify that components adhere to tolerances, thus preventing issues during assembly and operation.

- Machining Machinists often need to validate the internal diameters of the workpieces they create. Using a bore gauge, they can ensure that the diameters meet design specifications, thereby producing parts that function correctly.

- Maintenance In machinery maintenance, assessing wear and tear is vital. Bore gauges assist technicians in measuring the internal dimensions of components, helping them determine whether repairs or replacements are necessary.

Benefits of Using the Starrett Bore Gauge

Adopting the Starrett Bore Gauge in your measurement toolkit offers numerous benefits

1. Improved Quality With precise measurements, manufacturers can produce higher quality parts, reducing the chances of defects and rework.

2. Efficiency The ease of use and speed of measurement allows operators to work efficiently, improving overall productivity.

3. Cost-Effectiveness While the initial investment in a quality bore gauge may seem significant, the long-term benefits of accuracy, durability, and reduced errors can lead to significant cost savings.

4. Enhanced Skill Development Using advanced tools like the Starrett Bore Gauge can help technicians and machinists refine their skills, fostering a culture of precision in their work.

Conclusion

In summary, the Starrett Bore Gauge represents a fusion of precision engineering and user-centric design. Its features, versatility, and application across various industries make it an indispensable tool for anyone involved in mechanical engineering and manufacturing. By investing in a Starrett Bore Gauge, professionals can ensure accuracy in their measurements, ultimately leading to better products and greater satisfaction in the workplace. The bore gauge not only reflects the quality of Starrett's craftsmanship but also exemplifies the importance of precision in the modern industrial landscape.

-

Flanged Gate Valve: A Reliable Choice for Industrial and Municipal SystemsNewsAug.20,2025

-

Soft Seal Gate Valve: A Modern Solution for Reliable Pipeline ControlNewsAug.20,2025

-

Gate Valve Types: Understanding the Options for Your Pipeline SystemsNewsAug.20,2025

-

Y Type Strainer: Essential for Clean and Efficient Flow SystemsNewsAug.20,2025

-

Cast Iron Y Strainer: Durable Solutions for Demanding ApplicationsNewsAug.20,2025

-

Flanged Y Strainer: An Essential Component in Industrial Filtration SystemsNewsAug.20,2025

Related PRODUCTS