Noy . 29, 2024 11:34 Back to list

Precision Granite Master Square for Accurate Measurements and Professional Craftsmanship in Woodworking

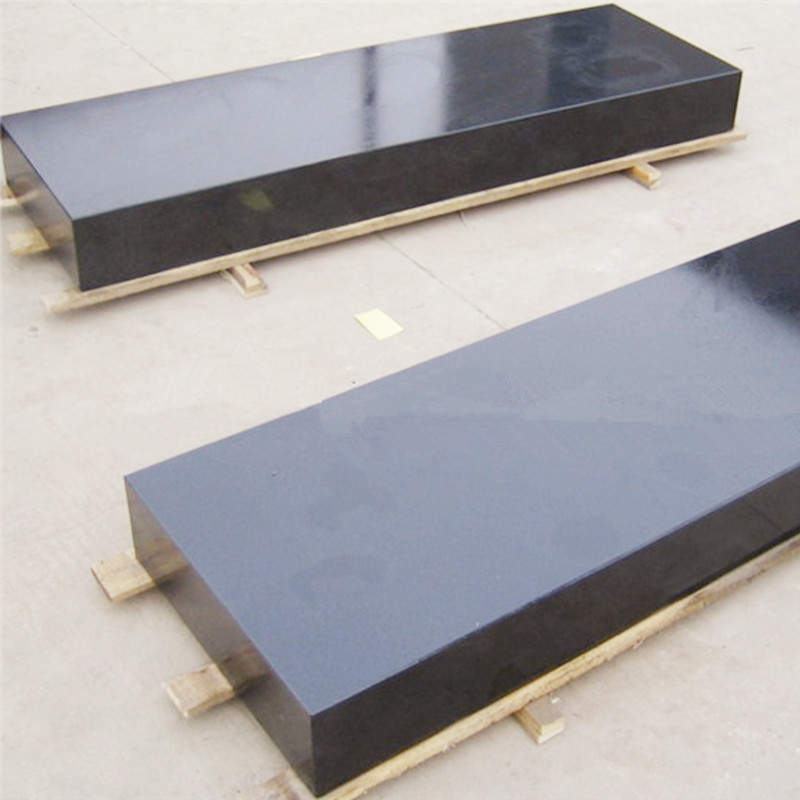

Precision Granite Master Square The Benchmark of Accuracy in Metalworking

In the realm of precision measurement tools, few items are as essential as the granite master square. The precision granite master square is a highly regarded instrument in metalworking and machining, revered for its accuracy and reliability. This tool serves as a cornerstone for ensuring that parts and assemblies meet stringent tolerances, making it indispensable in fields ranging from engineering to woodworking.

Understanding the Granite Master Square

At its core, the granite master square is a L-shaped tool made from high-quality granite. The choice of granite as the material stems from its unique properties it is dense, stable, and resistant to wear and deformation. Unlike metal squares that can warp or lose their edges over time, a granite master square maintains its precision across years of use. This stability is crucial for achieving consistent and accurate results, especially in environments where temperature variations and heavy usage might compromise other measurement tools.

Design and Features

A typical precision granite master square includes two arms that meet at a right angle. Each arm is meticulously ground and polished to create a flat surface that is uniform and devoid of imperfections. The edges are crafted to be sharp and true, allowing for accurate height measurements and alignment checks. The surface finish of a granite master square is pivotal; the finer the finish, the more accurate the reading.

Many granite master squares come with engraved calibration markings. These markings assist professionals not only in making accurate measurements but also in quickly assessing the dimensions of workpieces. The clear visibility of these markings is crucial during detailed work where precision is paramount.

Applications in Metalworking

precision granite master square

The granite master square has a variety of applications in the metalworking industry. It is often used for setting up machinery, checking squareness in machining operations, and verifying the accuracy of manufactured parts. For instance, when fabricating a new component, a machinist can use the granite master square to ensure that the corners of the piece are perfectly square. This verification step helps prevent problems down the line, such as misalignment or difficulties during assembly.

Another critical use of the granite master square is in quality control processes. Inspectors rely on this tool to measure critical dimensions and geometrical features of parts. By ensuring that components adhere to required specifications, manufacturers can maintain high standards and reduce waste caused by defective parts.

Benefits of Using a Granite Master Square

One of the most significant advantages of using a precision granite master square is its accuracy. For many metalworkers, even a small deviation can lead to catastrophic failures in assembly or function. The granite master square provides the level of precision necessary to avoid such outcomes. Additionally, its robust nature means that it can withstand the rigors of a machine shop environment without losing its measuring properties.

Moreover, granite master squares are relatively low maintenance compared to other measuring tools. They do not require recalibration as frequently as dial indicators or other electronic devices, making them a cost-effective choice for workshops looking to maintain a high level of efficiency. The non-porous surface of granite also makes it resistant to oil and contaminants, which is particularly advantageous in environments where exposure to substances could affect measurement integrity.

Conclusion

In conclusion, the precision granite master square stands as a symbol of accuracy and reliability in the metalworking industry. Its stable properties, precision manufacturing, and multifaceted applications make it an essential tool for both machinists and quality control inspectors. Investing in a high-quality granite master square is not just about acquiring a measuring tool; it's about ensuring the success of precision work and upholding standards of excellence. As the demand for precision in manufacturing continues to grow, the granite master square remains a fundamental instrument, quietly enabling the creation of high-quality parts and products that define the modern industrial landscape.

-

Thread Plug Gauge Our Promise of Measurement ExcellenceNewsAug.22,2025

-

Gauge Pin Class Reflecting Quality LegacyNewsAug.22,2025

-

Check Valve Types for High Rise BuildingsNewsAug.22,2025

-

Water Control Valve for Irrigation SystemsNewsAug.22,2025

-

Gate Valve with Soft Seal TechnologyNewsAug.22,2025

-

Y Type Strainer for Oil and Gas ApplicationsNewsAug.22,2025

Related PRODUCTS