دسمبر . 03, 2024 18:40 Back to list

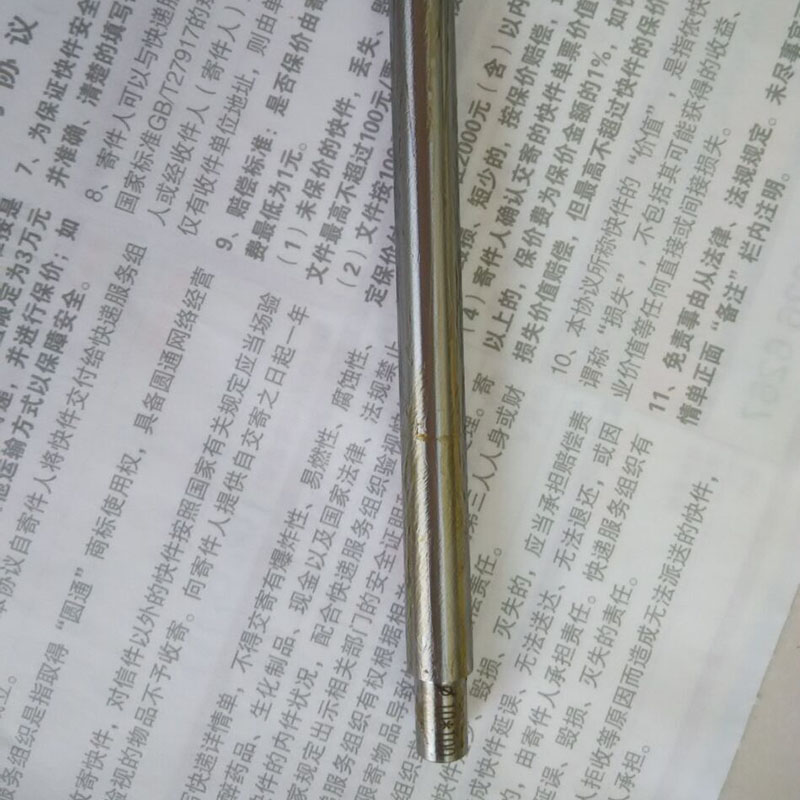

3 inch check valve

Understanding 3 Inch Check Valves A Comprehensive Guide

Check valves are critical components in various fluid systems, designed to prevent backflow and ensure that fluid flows in only one direction. Among the various sizes available, the 3-inch check valve stands out due to its versatility and effectiveness in both residential and industrial applications. This article delves into the functionality, types, applications, and importance of 3-inch check valves.

Functionality of Check Valves

Check valves operate on a simple yet effective principle. They consist of three main components the body, the disc (or gate), and the seat. When fluid flows in the intended direction, the disc is pushed open, allowing flow through the valve. Conversely, if the fluid attempts to flow back, the disc closes against the seat, effectively sealing off the flow and preventing reverse movement.

This one-way flow mechanism is crucial for maintaining system pressure and preventing potential damage due to backflow. In many systems, backflow can lead to contamination, loss of pressure, or even system failure, making check valves indispensable in piping systems.

Types of 3 Inch Check Valves

3-inch check valves come in several types, each designed for specific applications and environments

1. Swing Check Valve This type has a disc that swings on a hinge. It is typically used in situations where the flow is relatively constant and where space allows for its installation. Swing check valves are ideal for low-pressure applications.

2. Lift Check Valve Instead of swinging like the previous type, the lift check valve features a disc that moves vertically. These valves are used for applications involving higher pressure where a tighter seal is necessary.

3. Ball Check Valve In this design, a ball moves within the valve body to prevent backflow. Ball check valves are often used in applications that require quick response times to changes in pressure.

4. Tilting Disc Check Valve This type combines features of both swing and lift valves. The disc tilts in response to flow, providing a more efficient sealing mechanism and reducing the risk of cavitation.

Each type of 3-inch check valve has unique benefits and considerations, making it important for engineers and system designers to select the appropriate type for their specific needs.

3 inch check valve

Applications of 3 Inch Check Valves

3-inch check valves are utilized across a wide range of industries, including

- Water and Wastewater Treatment These valves prevent backflow in treatment plants, ensuring that contaminated water does not re-enter clean water systems.

- Oil and Gas In the oil and gas sector, check valves are essential for maintaining line integrity and preventing reverse flow in pipelines.

- HVAC Systems Check valves help in managing water flow and pressure within heating and cooling systems, contributing to system efficiency.

- Fire Protection Systems In fire suppression systems, check valves are crucial for ensuring that water flows properly to fire hydrants and sprinklers without backflow.

Importance of Regular Maintenance

While 3-inch check valves are built to last, regular maintenance is key to ensuring their longevity and effectiveness. Factors like corrosion, sediment buildup, and wear can affect valve performance. Routine inspections can help identify potential issues before they escalate, ultimately saving costs and preventing system failures.

Maintenance tasks may include cleaning, checking for leaks, and ensuring that the valve operates smoothly without obstructions. For critical applications, it may be advisable to replace older valves with new ones to avoid the risk of failure.

Conclusion

3-inch check valves play a vital role in protecting fluid systems from backflow, making them essential in various industries. By understanding the different types, applications, and maintenance needs, engineers and facility managers can make informed decisions that enhance system reliability and performance. As industries continue to evolve, the importance of effective fluid control solutions, like check valves, will remain paramount in ensuring operational efficiency and safety.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS