Гру . 05, 2024 20:28 Back to list

Understanding Thread Screw Measurement Techniques and Their Applications

Understanding Thread Screw Gauges Importance and Applications

A thread screw gauge, often referred to as a screw thread gauge or simply a thread gauge, is an essential tool in various industries, particularly in engineering, manufacturing, and Mechanics. This device is invaluable for measuring the pitch and diameter of threaded fasteners, ensuring that components fit together seamlessly in assembly processes. Understanding the significance and application of thread screw gauges can illuminate their importance in quality control and product development.

What is a Thread Screw Gauge?

A thread screw gauge is a measuring instrument designed to assess the dimensions of screw threads. It typically consists of a series of blades or leaves, each marked with different thread sizes and pitches. These blades are used to measure the external and internal threads of screws and nuts, helping to determine whether they adhere to industry standards.

The most common types of thread gauges include the screw pitch gauge and the ring gauge. The screw pitch gauge measures the distance between the threads, known as pitch, which is crucial for determining whether two threaded components will fit together. The ring gauge, on the other hand, is used to check the internal dimensions of a threaded hole, ensuring that bolts or screws can be properly inserted.

Importance of Thread Screw Gauges

1. Accuracy in Manufacturing One of the primary reasons for using tread screw gauges is to ensure precision in manufacturing processes. When designing parts that will be assembled together, accurate measurements are vital. A miscalculation in the thread dimensions can lead to assembly failures, potentially causing safety issues or equipment malfunctions.

2. Quality Control In any production environment, maintaining quality control is essential. Thread screw gauges provide a reliable means of verifying that manufactured parts conform to specified standards. By consistently checking the dimensions of threads, manufacturers can avoid defects that may lead to increased costs or product recalls.

3. Standardization Thread screw gauges help standardize measurements across different industries. Various standards, such as the Unified Thread Standard (UTS) or the International Organization for Standardization (ISO), dictate specific thread dimensions. By using thread gauges calibrated to these standards, manufacturers can ensure compatibility between components from different producers.

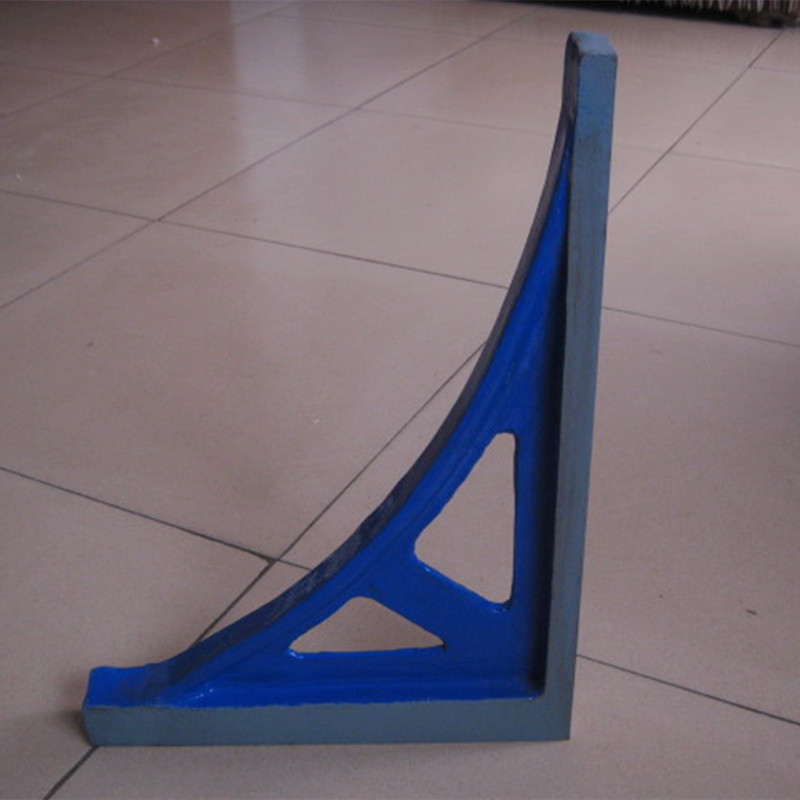

thread screw gauge

4. Facilitating Repairs and Maintenance In industries such as automotive and aerospace, maintenance of complex machinery involves replacing or repairing threaded components. Using a thread screw gauge allows technicians to quickly and accurately assess which replacement parts are necessary. This efficiency in maintenance minimizes downtime and keeps machinery running smoothly.

Applications Across Industries

Thread screw gauges find applications in a wide range of industries.

- Automotive In vehicle manufacturing and repair, thread gauges ensure that bolts and screws used in engines and chassis conform to precise specifications, contributing to the overall safety and reliability of vehicles.

- Aerospace In the aerospace industry, where precision is paramount, thread gauges are used to verify the dimensions of threaded parts in aircraft. This adherence to strict standards ensures that components can withstand the extreme conditions faced during flight.

- Construction Thread screw gauges play a critical role in the construction industry, particularly in checking the dimensions of screws and bolts used in structures. Ensuring proper threading is vital for the longevity and safety of buildings and infrastructure.

- Manufacturing In general manufacturing, thread gauges assist in various production processes, from creating everyday household items to complex machinery, ensuring that every threaded component meets necessary specifications for functionality.

Conclusion

In conclusion, thread screw gauges are indispensable tools for ensuring the accuracy, quality, and reliability of various threaded components across multiple industries. Their ability to facilitate precise measurements makes them essential in manufacturing, maintenance, and quality control processes. Understanding how to use and maintain these gauges can significantly impact the success of manufacturing operations and the safety of the end products. As industries continue to evolve, the importance of such precise measuring instruments will undoubtedly remain a cornerstone of engineering practices.

-

thread-plug-gauge-our-promise-of-measurement-excellenceNewsAug.22,2025

-

gauge-pin-class-reflecting-quality-legacyNewsAug.22,2025

-

check-valve-types-for-high-rise-buildingsNewsAug.22,2025

-

water-control-valve-for-irrigation-systemsNewsAug.22,2025

-

gate-valve-with-soft-seal-technologyNewsAug.22,2025

-

y-type-strainer-for-oil-and-gas-applicationsNewsAug.22,2025

Related PRODUCTS