Чер . 24, 2025 10:44 Повернутися до списку

Cast Iron Welding Tables for Blacksmithing Projects

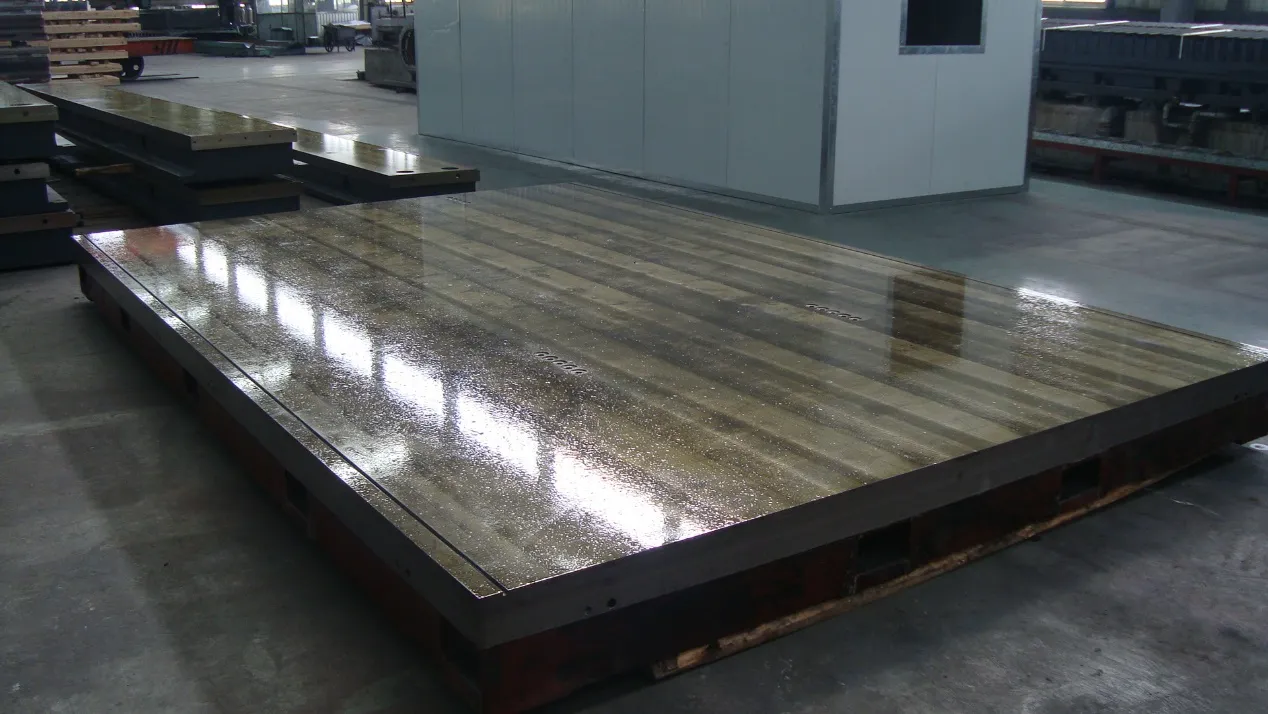

Blacksmithing is an art that demands precision, durability, and the right tools. Among the most critical tools in a blacksmith’s workshop is a reliable welding table. Specifically, a welding table cast iron offers unmatched stability and heat resistance, making it a cornerstone for crafting high-quality metalwork. For hobbyists and professionals alike, finding an affordable welding table that doesn’t compromise on functionality can elevate projects from mundane to extraordinary. In this article, we explore why cast iron welding tables are indispensable, their key features, and how to choose one that fits your needs and budget.

Why a Зварювальний верстак is Essential for Blacksmithing

A welding workbench is more than just a flat surface—it’s the foundation of every successful blacksmithing project. Unlike ordinary tables, a dedicated welding bench is designed to withstand extreme temperatures, heavy hammering, and the rigors of metal fabrication. Cast iron, in particular, excels in this role due to its high thermal mass, which absorbs heat without warping. This ensures your workpiece remains stable, even during prolonged welding or forging sessions.

Additionally, a welding workbench often includes features like built-in clamps, tool holders, and slots for securing materials. These elements streamline workflows, allowing blacksmiths to focus on creativity rather than struggling with unstable setups. For those working on intricate designs, the flat, non-flexible surface of a cast iron table ensures accuracy, reducing errors and material waste.

Investing in a high-quality welding table cast iron also enhances safety. Its weight and sturdy construction minimize vibrations, preventing tools or hot metal from shifting unexpectedly. Whether you’re crafting decorative ironwork or heavy-duty tools, a reliable workbench is a non-negotiable asset.

The Superior Durability of a Welding Table Cast Iron

When it comes to longevity, few materials rival cast iron. A welding table cast iron is engineered to endure decades of use, resisting dents, scratches, and corrosion. This resilience stems from cast iron’s dense molecular structure, which distributes weight and impact evenly across the surface. Unlike steel or aluminum, cast iron doesn’t flex under pressure, maintaining its flatness even after years of heavy pounding.

Heat resistance is another standout feature. Blacksmithing involves temperatures that can warp lesser metals, but cast iron’s ability to absorb and dissipate heat protects both the table and your workpiece. This makes it ideal for tasks like forge welding, where localized heating is common.

Maintenance is straightforward: periodic cleaning and a light coat of oil prevent rust, ensuring your welding table cast iron remains in pristine condition. For blacksmiths seeking a "buy it for life" tool, cast iron’s durability justifies its initial cost, especially when compared to replacing cheaper tables repeatedly.

Finding an Affordable Welding Table Without Sacrificing Quality

The term affordable welding table might conjure images of flimsy, short-lived products, but this isn’t always the case. Many manufacturers now offer budget-friendly cast iron tables that retain the core benefits of premium models. The key is to prioritize essential features—like thickness, weight, and surface finish—while avoiding unnecessary add-ons that inflate costs.

For example, a mid-range welding table cast iron might lack decorative flourishes but still provide a thick, machined-flat top and reinforced legs. Shopping during sales or opting for factory-direct purchases can also reduce expenses. Additionally, consider modular designs that allow you to expand your workspace incrementally, spreading out costs over time.

Another cost-saving strategy is to focus on versatility. An affordable welding table that doubles as a general-purpose workbench maximizes value, serving as a grinding station, assembly area, or even a temporary anvil. By balancing price and practicality, you can acquire a durable table that supports your craft without straining your budget.

FAQs: Your Questions About Зварювальний верстак, Welding Table Cast Iron, and Affordable Welding Table Answered

What Makes a Welding Table Cast Iron Better Than Steel?

Cast iron outperforms steel in heat absorption and vibration dampening. Its dense structure minimizes warping under high temperatures, making it ideal for blacksmithing. Steel tables, while strong, often require additional bracing to match cast iron’s stability.

Can an Affordable Welding Table Handle Heavy-Duty Projects?

Yes! Many budget-friendly tables use thick cast iron tops and reinforced legs. Look for tables rated for at least 1,000 lbs to ensure they can withstand heavy forging and welding tasks.

How Do I Maintain My Зварювальний верстак?

Clean the surface after each use to remove debris and apply a light oil coating to prevent rust. Avoid exposing the table to moisture for extended periods.

Are Welding Table Cast Iron Surfaces Truly Flat?

High-quality cast iron tables are machined to precise flatness tolerances. This ensures consistent performance, especially for projects requiring exact measurements.

Why Should I Choose an Affordable Welding Table Over Building My Own?

While DIY tables can be cost-effective, they often lack the precision and durability of professionally cast iron tables. Premade options save time and guarantee a reliable surface.

A welding table cast iron is an investment that pays dividends in precision, safety, and longevity. Whether you opt for a no-frills affordable welding table or a feature-rich welding workbench, prioritizing cast iron ensures your projects stand on solid ground. By understanding the material’s benefits and evaluating your needs, you can select a table that fuels your creativity for years to come. Happy forging!

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlНовиниAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseНовиниAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsНовиниAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesНовиниAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingНовиниAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlНовиниAug.05,2025

Супутні товари