Гру . 16, 2024 17:50 Back to list

24 butterfly valve

Understanding 24% Butterfly Valves Applications and Benefits

Butterfly valves are integral components in various industrial processes, often utilized for regulation and isolation of flow. Among the continuum of designs available in the market, the 24% butterfly valve presents unique specifications that cater to specific operational needs. This article delves into the features, applications, and benefits of the 24% butterfly valve, providing an in-depth understanding of its utility in various sectors.

What is a Butterfly Valve?

A butterfly valve is a type of flow control device that consists of a rotating disc, referred to as a butterfly, which is positioned in the center of a pipe. The rotation of the disc regulates the flow of liquid or gas by either opening or closing the passage. Butterfly valves are appreciated for their simple design, which allows for quick and efficient flow regulation, making them a popular choice in various industries.

The 24% Butterfly Valve Key Features

While butterfly valves are available in different sizes and specifications, the 24% designation typically refers to the degree of opening that provides optimal flow performance. This percentage can indicate the optimal position of the valve disc to streamline the flow characteristics while minimizing resistance.

The construction of a 24% butterfly valve generally involves robust materials designed to withstand high pressures and temperatures, depending on the application. Common materials include stainless steel, carbon steel, and various alloys, ensuring durability and longevity in demanding environments.

Applications of 24% Butterfly Valves

1. Water Treatment Plants In water and wastewater management, 24% butterfly valves are valued for their ability to control the flow of water effectively. They can manage the movement of water through filtering, sedimentation, and disinfection processes.

2. Chemical Processing These valves are commonly utilized in the chemical industry for regulating the flow of corrosive substances. The capacity to withstand harsh conditions and handle varying flow rates makes them an essential component in chemical manufacturing processes.

24 butterfly valve

3. HVAC Systems In heating, ventilation, and air conditioning systems, 24% butterfly valves help control air and fluid flow, enhancing energy efficiency. Their compact design allows for easy installation in tight spaces, further contributing to their appeal in HVAC applications.

4. Power Generation In power plants, whether they are coal, natural gas, or nuclear-based, 24% butterfly valves perform a critical role in managing steam and cooling water flow, ensuring system efficiency and safety.

5. Food and Beverage Industry The sanitary design of some 24% butterfly valves makes them suitable for food processing and beverage production. They are easy to clean, ensuring that hygiene regulations are met without sacrificing flow efficiency.

Benefits of Using 24% Butterfly Valves

The implementation of 24% butterfly valves brings numerous advantages to various industries. Firstly, their lightweight and compact design facilitate easy installation, saving valuable time and labor costs during the setup phase. Additionally, their design supports quick opening and closing capabilities, allowing for efficient automated control of flow.

Another significant benefit is the reduced pressure drop associated with butterfly valves compared to traditional gate or globe valves. This characteristic leads to energy savings in systems where pressure and energy consumption are critical factors. Moreover, the seamless operation reduces wear and tear on other components in the system, promoting a longer lifespan for the entire assembly.

Lastly, the versatility of 24% butterfly valves means they can easily be integrated into existing piping systems with minimal modifications, providing a flexible solution for engineering challenges.

Conclusion

In summary, the 24% butterfly valve serves as a crucial component across various sectors, characterized by its efficient flow control and robust design. Its versatility and benefits extend from water treatment to chemical processing, making it a valuable asset in both industrial and commercial applications. By understanding the intricacies of butterfly valves, engineers and operators can better leverage their capabilities, ensuring optimal performance and reliability in their respective systems. As industries continue to evolve, the role of innovative flow control devices like the 24% butterfly valve remains paramount in achieving operational excellence.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

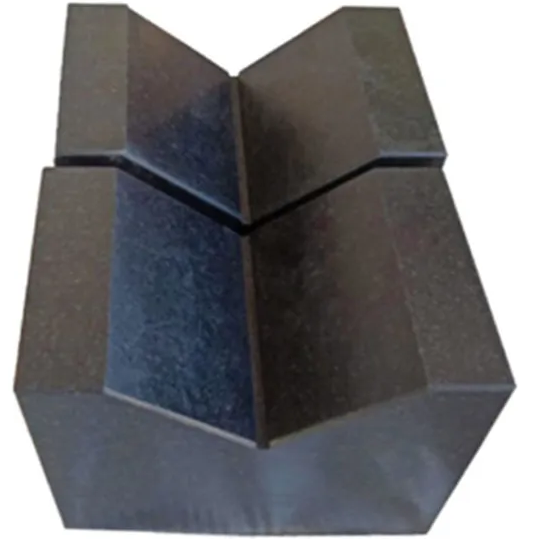

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS