ئۆكتەبىر . 19, 2024 13:05 Back to list

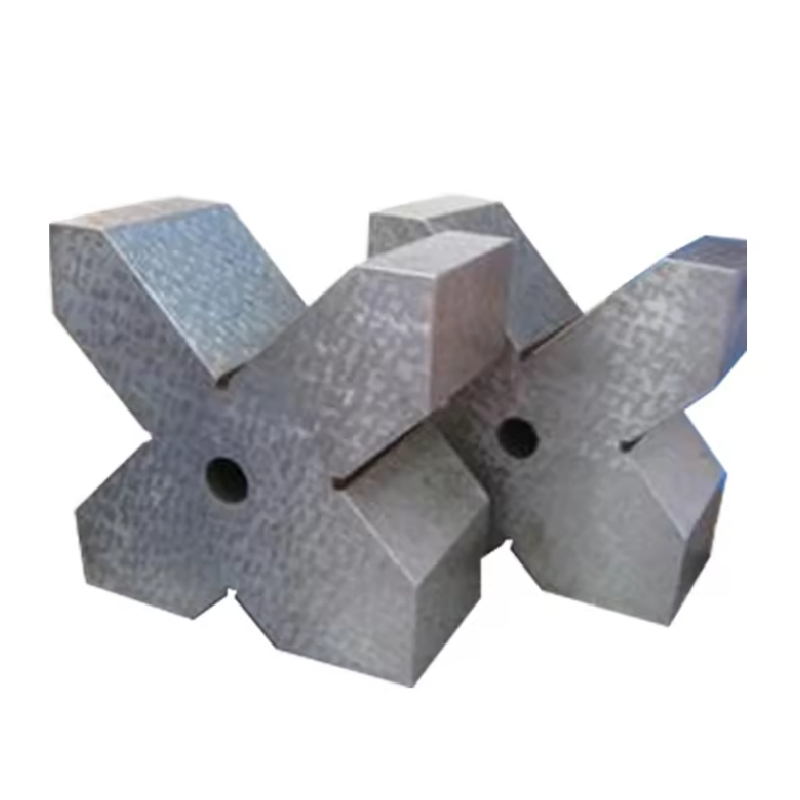

welding v block

The Importance of Welding V Blocks in Precision Manufacturing

In the realm of precision manufacturing, the role of welding V blocks cannot be understated. These specialized tools are pivotal in ensuring that components are held securely during welding operations, allowing for accurate joints and consistent quality in the final product. This article explores the significance of welding V blocks, their design, usage, and impact on the manufacturing industry.

What is a Welding V Block?

A welding V block is a fixture designed to hold cylindrical or irregularly shaped workpieces at an angle. The “V” shape provides a dual benefit it offers a stable base while aligning the workpiece for welding operations. Traditionally made from steel or other durable materials, these blocks are equipped to endure the extreme conditions of welding, including heat and structural stress.

Design Features

The design of a welding V block is crucial for its effectiveness. The V-shaped groove is often adjustable, allowing for various diameters and sizes of workpieces to be securely held. Many welding V blocks come with integrated clamps or bolts, ensuring that the components do not shift during the welding process. Additionally, features like machined surfaces and precise angles enhance the accuracy of the welds, contributing to the overall quality of the finished product.

Applications in Manufacturing

Welding V blocks find applications across various industries, including automotive, aerospace, and metal fabrication. In the automotive sector, for instance, they are essential for assembling frames, supporting components like pipes and tubes that require precise alignment. In the aerospace industry, where safety and precision are paramount, welding V blocks help in constructing aircraft components accurately. Moreover, in metal fabrication, these fixtures allow for efficient and reliable welding in the assembly of custom components.

welding v block

Using welding V blocks streamlines the production process. By securely holding the workpieces in position, they minimize the need for secondary operations, such as grinding or reworking misaligned joints. This efficiency not only saves time but also reduces material waste, ultimately lowering manufacturing costs.

The Impact on Quality

Quality control is a critical aspect of any manufacturing process, and the use of welding V blocks significantly enhances this aspect. The precision provided by these blocks ensures that the welds are consistent and meet the required specifications. This is particularly important in industries where even minor defects can lead to catastrophic failures.

The integrity of a weld is often determined by how well the materials are aligned during the welding process. A misalignment can lead to weak joints, increasing the risk of failure under stress. Welding V blocks minimize this risk by providing a stable and predictable work environment. As a result, manufacturers can achieve higher quality standards and better overall performance in their products.

Conclusion

Welding V blocks are an essential tool in the arsenal of precision manufacturing equipment. Their unique design and functional benefits enable efficient, accurate, and high-quality welding operations across various industries. By improving alignment and reducing the risk of defects, these blocks contribute significantly to the manufacturing process. As industries continue to advance and demand greater precision and quality, welding V blocks will undoubtedly play a crucial role in meeting these challenges.

In summary, the use of welding V blocks represents a marriage of simplicity and practicality in manufacturing. They exemplify how a well-designed tool can enhance production efficiency and quality, making them indispensable for professionals in the field. As technologies evolve, the ongoing innovation in tools like welding V blocks will continue to shape the future of manufacturing, ensuring that quality and precision remain at the forefront of the industry.

-

Precision Manufacturing with Advanced Spline Gauge DesignNewsJul.31,2025

-

Industrial-Grade Calibrated Pin Gauges for Exact MeasurementsNewsJul.31,2025

-

Industrial Filtration Systems Depend on Quality Filter DN50 SolutionsNewsJul.31,2025

-

High-Performance Gate Valve WholesaleNewsJul.31,2025

-

Granite Surface Plate The Ultimate Solution for Precision MeasurementNewsJul.31,2025

-

Granite Industrial Tools The Ultimate Guide for Bulk BuyersNewsJul.31,2025

Related PRODUCTS