دېكابىر . 12, 2024 11:48 Back to list

surface plate

The Importance of Surface Plates in Precision Measurement

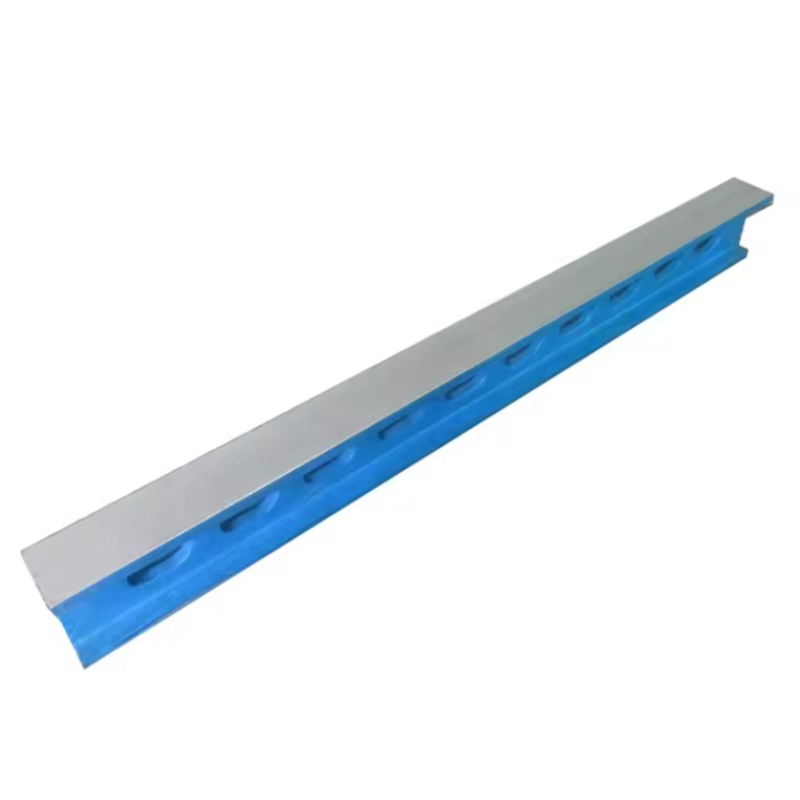

When it comes to achieving precise measurements in manufacturing and engineering, the importance of a high-quality surface plate cannot be overstated. Surface plates serve as a fundamental tool for measuring, supporting, and inspecting various components across diverse industries. Their design, material, and applications make them essential instruments in precision measurement processes.

A surface plate is essentially a flat, stable support structure made from materials such as granite, cast iron, or stainless steel. The choice of material is crucial as it affects the plate's durability, thermal stability, and ability to resist wear. Among these materials, granite is often favored due to its inherent stability and resistance to deformation. Cast iron plates, on the other hand, can offer greater resilience under heavy loads but may be subject to rust if not adequately maintained. Stainless steel plates are known for their resistance to corrosion, making them suitable for environments where exposure to moisture or certain chemicals is a concern.

The primary purpose of a surface plate is to provide a reference plane for dimensional measurement. In inspecting workpieces or assemblies, a surface plate acts as a baseline from which measurements can be taken. This is particularly important in industries where precision is paramount, such as aerospace, automotive, and semiconductor manufacturing. By placing a component on a surface plate, engineers can use various measuring tools—like calipers, micrometers, or coordinate measuring machines (CMMs)—to assess dimensions accurately, ensuring that they meet rigorous specifications.

surface plate

An essential characteristic of surface plates is their flatness. A high-quality surface plate can achieve a flatness tolerance much tighter than many other surfaces encountered in manufacturing. This precision is vital, as even minor deviations can lead to significant errors in measurement and, subsequently, in the production process. Regular calibration and maintenance of surface plates are paramount to preserving their accuracy. Users should clean the plates regularly to remove any debris and ensure they are stored correctly to prevent damage.

Surface plates can also come equipped with additional features, such as T-slots, which allow for the attachment of other measurement tools, clamps, or fixtures. These modifications can enhance their versatility and convenience, making them practical for various tasks and setups. Portable surface plates, made from lightweight materials, are also available for use in field situations or smaller workshops where space is a constraint.

Education and training in the proper use of surface plates are crucial for quality control personnel. Understanding how to position components accurately, read measurement tools, and interpret results correctly can significantly influence the efficiency and accuracy of the measurement process. Moreover, knowledge of how to maintain and calibrate these plates ensures they continue to provide reliable performance over time.

In conclusion, surface plates are indispensable assets in precision measurement and quality control processes across multiple industries. Their design, materials, and functional capabilities make them instrumental in ensuring that manufactured parts meet stringent specifications. As industries continue to embrace more advanced technologies and methodologies, the role of surface plates remains vital, highlighting the need for ongoing investment in their quality, maintenance, and operator training. The pursuit of precision is a continuous journey, and surface plates are at the forefront of this essential endeavor.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS