نويابىر . 07, 2024 21:45 Back to list

Snap Check Gauge for Precision Measurement and Quality Control Solutions

Understanding Snap Check Gauge Importance and Applications

In the modern manufacturing and engineering landscapes, precision is key to ensuring quality and performance. One tool that embodies this precision is the snap check gauge, a device that plays a critical role in measuring and assessing dimensional characteristics of parts. In this article, we will explore the fundamentals of the snap check gauge, its applications, and its significance in quality control processes.

What is a Snap Check Gauge?

A snap check gauge, often referred to simply as a snap gauge, is a mechanical measuring device used to determine the dimensions of an object, particularly its external measurements. These gauges are designed to provide quick, accurate, and repeatable measurements, making them essential in a variety of industrial settings. Typically, snap gauges are utilized to check the tolerances of parts, ensuring they meet specified criteria for production.

The structure of a snap check gauge generally comprises two jaws that are used to snap over the object being measured. The user applies a small amount of pressure, causing the jaws to close around the part. The measurement is read from a dial or digital display, providing immediate feedback on the part’s dimensions. This simplicity and speed make snap gauges incredibly useful in high-volume manufacturing processes.

Importance in Quality Control

Quality control is a fundamental aspect of manufacturing that ensures products meet certain standards before they reach the market. Snap check gauges contribute significantly to this process. By allowing operators to quickly measure parts on the production line, they help to catch defects early, minimizing waste and the risk of costly recalls.

Moreover, using snap gauges minimizes human errors in measurement. Traditional measuring tools, such as calipers or micrometers, may require more time and skill to use effectively, while snap gauges provide a more straightforward approach. This ease of use makes it possible for less experienced operators to achieve high levels of accuracy.

snap check gauge

Applications of Snap Check Gauges

Snap check gauges are employed across various industries, including automotive, aerospace, and manufacturing. In the automotive industry, for example, maintaining precise measurements is vital for ensuring that parts fit together correctly and function as intended. A miscalculated dimension can lead to assembly issues, affecting the vehicle's performance and safety.

In the aerospace sector, the stakes are even higher. Components must adhere to stringent specifications and tolerances due to the potential risks associated with flight. Snap check gauges ensure that each piece meets the exact criteria required for high-performance applications, thereby enhancing safety and reliability.

Additionally, snap gauges are crucial in the production of electronic components, where minute variations can significantly impact functionality. By incorporating snap gauges into their quality control processes, manufacturers can ensure that every component adheres to required tolerances, ultimately leading to more successful end products.

Conclusion

The snap check gauge is an indispensable tool in the realm of quality control and precision manufacturing. Its ability to deliver quick and accurate measurements not only facilitates easy inspections on the production line but also contributes to the overall efficiency of manufacturing processes. As industries continue to demand higher standards of quality and precision, the role of snap check gauges will only become more prominent.

In summary, understanding the importance and functionality of snap check gauges is essential for professionals within the manufacturing and engineering sectors. These tools not only ensure that products adhere to required specifications but also enhance the overall quality and reliability of manufactured goods. By investing in such measuring devices, companies can significantly improve their quality control processes and ultimately deliver superior products to the market.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

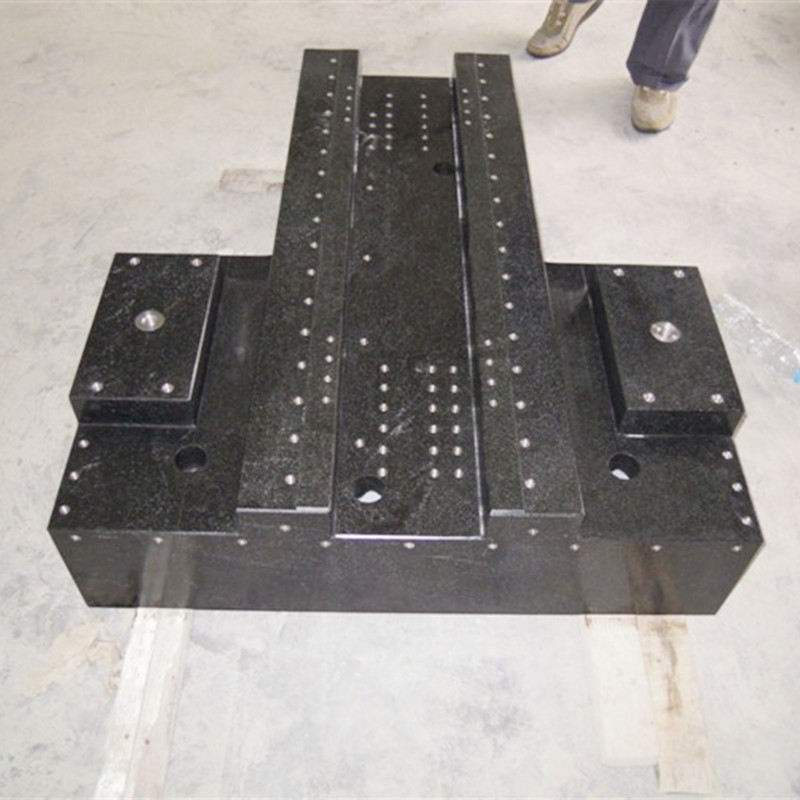

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS