نويابىر . 06, 2024 01:25 Back to list

Types of Threads for Pressure Gauge Connections and Their Applications

Understanding Pressure Gauge Thread Types An Essential Guide

Pressure gauges are vital instruments used in various industries to measure the pressure of gases and liquids. They contribute to the efficiency, safety, and reliability of different systems, from residential plumbing to complex industrial machinery. One crucial aspect of installing and utilizing pressure gauges is understanding the various thread types that are used for connecting these instruments. The choice of thread type directly impacts the sealing effectiveness, installation process, and overall performance of the pressure gauge.

Common Thread Types

1. NPT (National Pipe Tapered) NPT threads are one of the most commonly used tapered threads in the United States. They provide a tight seal thanks to the conical shape, which allows for a compression fit when connected. This feature is particularly important in applications involving liquids and gases at varying pressures. When using NPT threads, it’s essential to apply thread sealant tape or paste to prevent leaks and ensure a secure connection.

2. BSP (British Standard Pipe) Similar to NPT, BSP threads are also tapered but are predominantly used in the UK and other countries. There are two primary types BSPP (BSP Parallel) and BSPT (BSP Tapered). The choice between these depends on the specific application requirements. BSP threads require specific sealing methods; for example, BSPP connections often use O-rings or flat washers for sealing, while BSPT relies on the threads themselves for a tight fit.

3. PT (Pipeline Thread) PT threads are a variant of BSPT and are commonly used in European countries. Like BSPT, PT threads are tapered and are designed to create a seal through the wedging action of the threads. When connecting PT threads, similar sealing techniques as those used for NPT and BSPT threads should be utilized to prevent leakage.

4. G (Parallel Gas) G threads, also known as ISO 7-1 or BSPP, are parallel connections that require O-ring seals to ensure leakage prevention. They are widely used in European applications and are especially favored in pneumatic systems. The lack of taper means that G threads can be unscrewed easily without damaging the sealing surface, making them versatile for various installations.

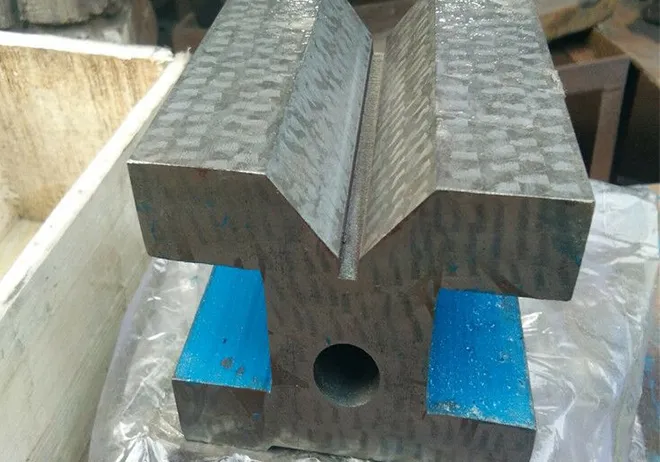

pressure gauge thread types

5. UNF/UNC (Unified National Fine/Coarse) While not as commonly used as pipe threads, UNF and UNC threads can sometimes be found on specialized pressure gauges, particularly those designed for specific machinery or precision applications. Their primary function is to provide mechanical fastening rather than fluid sealing, which means they may need additional sealing methods to ensure pressure control.

Choosing the Right Thread Type

When selecting a pressure gauge, it is essential to consider the thread type that matches your system requirements. Factors to take into account include the medium being measured (gas or liquid), pressure levels, and environmental conditions. Furthermore, compatibility with existing piping systems is critical to ensure smooth installation and effective operation.

Proper installation practices are also vital. Always check for the manufacturer's specifications regarding thread types and sealing practices. Each type may have unique requirements for torque and installation methods. Misinstallation can lead to leaks, malfunction, and potential hazards, particularly in high-pressure systems.

Conclusion

Understanding the various pressure gauge thread types is crucial for anyone involved in installation or maintenance tasks. NPT, BSP, PT, G, and UNF/UNC threads each serve specific functions and are optimized for different applications. By choosing the right thread type and following proper installation techniques, one can ensure the reliability and accuracy of pressure measurements, contributing to the overall safety and efficiency of their respective systems. As industries evolve, staying informed about thread standards and best practices will continue to be essential for professionals working with pressure measurements.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS