نويابىر . 15, 2024 21:28 Back to list

industrial tools and gauges

Understanding Industrial Tools and Gauges The Backbone of Precision Engineering

Industrial tools and gauges are indispensable components in the realm of manufacturing and engineering. Their significance extends beyond mere functionality; they represent precision, reliability, and efficiency in producing high-quality products. Whether it's a factory floor or a construction site, the right tools and gauges can mean the difference between success and failure.

The Role of Industrial Tools

Industrial tools can be categorized into several types, each serving a specific purpose in various processes. Hand tools like wrenches, screwdrivers, and pliers allow for manual adjustments and assembly. Power tools, including drills, saws, and grinders, enhance productivity, making tasks faster and easier. Additionally, specialized tools such as lathes, CNC machines, and welding equipment are essential for more complex manufacturing processes.

One of the primary advantages of modern industrial tools is their design, which often incorporates advanced materials and technologies. This innovation results in tools that are more robust and durable, enabling them to withstand the rigors of industrial use. For instance, high-carbon steel and titanium alloys are commonly used to enhance the lifespan and performance of cutting tools.

The Importance of Gauges

Gauges are precision instruments used to measure various parameters such as pressure, temperature, depth, and thickness. They play a critical role in quality control, ensuring that products meet specified tolerances. In industries like aerospace and automotive, where safety and performance are paramount, the accuracy of measurements obtained from gauges is not just beneficial but essential.

There are several types of gauges, including mechanical and digital variants. Mechanical gauges, like micrometers and calipers, have been staples in workshops for decades. These instruments offer the user tactile feedback, making them reliable choices for quick measurements. Digital gauges, on the other hand, provide enhanced accuracy and ease of use, often equipped with features such as data logging and connectivity to computers for seamless analysis.

industrial tools and gauges

Integration of Tools and Gauges

The interaction between tools and gauges is where the true power of industrial processes lies. For instance, consider a scenario where a machinist uses a CNC machine to shape a metal part. As the machine operates, gauges are employed to monitor the dimensions of the part being produced. If a deviation from specifications is detected, immediate adjustments can be made, saving time and resources.

Furthermore, the automation of industrial processes is increasingly incorporating both tools and gauges into integrated systems. Smart manufacturing utilizes IoT technology, where tools and gauges are connected to a central system that continuously collects data. This connectivity allows for real-time monitoring and predictive maintenance, significantly reducing downtime and improving productivity.

The Future of Industrial Tools and Gauges

As industries evolve with technology, so do the tools and gauges that drive them forward. The rise of automation and artificial intelligence is likely to transform how these instruments are used. Emerging trends such as 3D printing and robotics are creating new demands for precision tools and gauges, leading to the development of more sophisticated measuring devices.

Moreover, the focus on sustainability is making its way into tool and gauge manufacturing. Innovations aimed at reducing waste and enhancing energy efficiency are becoming important criteria for both manufacturers and end-users.

Conclusion

Industrial tools and gauges are fundamental to modern manufacturing and engineering processes. Their ability to provide precision and reliability is crucial in maintaining quality standards and efficiency in production. As technology continues to advance, the future holds promising developments that will enhance the capabilities of these indispensable instruments, ensuring that industries can meet the ever-growing demands of a competitive marketplace. Embracing these advancements will equip industries with the tools required to thrive in an increasingly complex world.

-

Understanding Different Valve Types in Wholesale ProcurementNewsJul.09,2025

-

Type of Strainer Maintenance Tips for LongevityNewsJul.09,2025

-

Measuring Tool Basics for EngineersNewsJul.09,2025

-

Level Ruler Maintenance TipsNewsJul.09,2025

-

Key Features of Different Types of Butterfly Valves for SaleNewsJul.09,2025

-

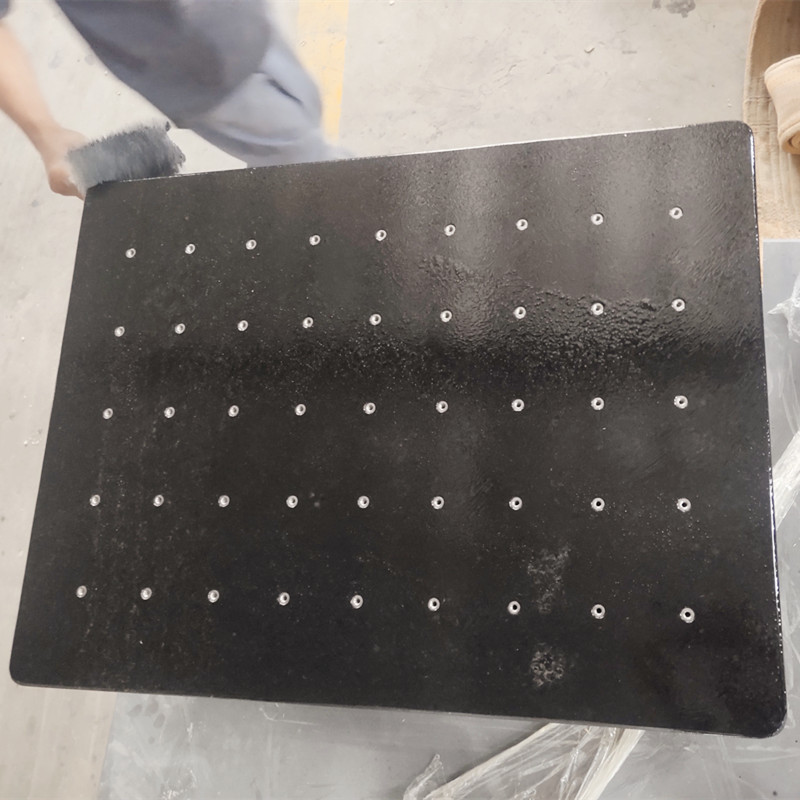

Features of Granite Inspection BlockNewsJul.09,2025

Related PRODUCTS