ئۆكتەبىر . 30, 2024 11:53 Back to list

equipment vibration pads

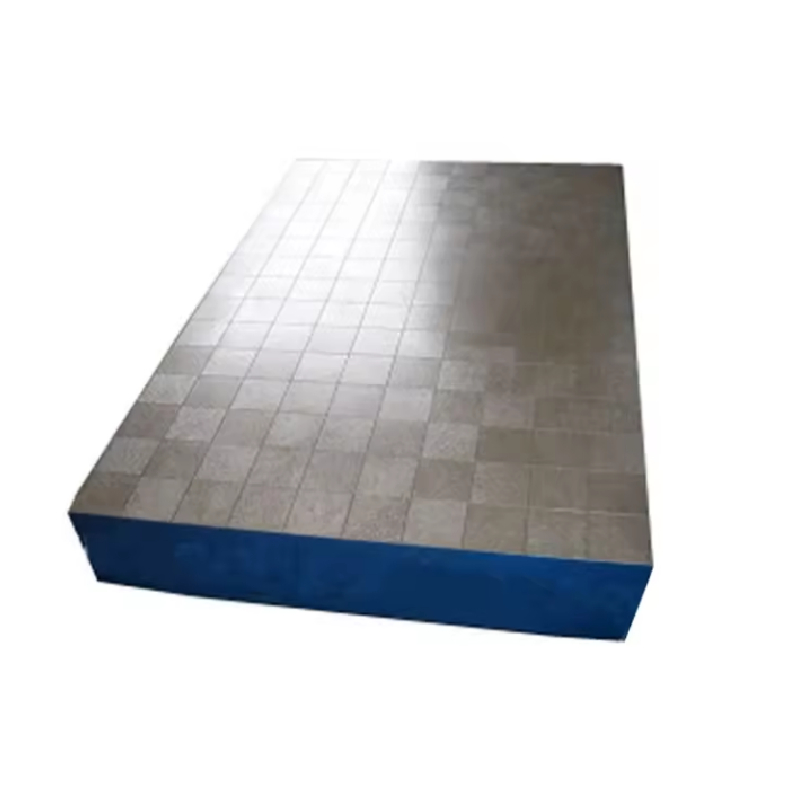

Understanding Equipment Vibration Pads Enhancing Stability and Performance

In various industrial and mechanical applications, equipment vibration can significantly impact performance, lifespan, and overall operational efficiency. One effective solution for mitigating these vibrations is the use of equipment vibration pads. These pads are designed to absorb and dampen vibrations, ensuring that machinery operates smoothly and efficiently.

Vibration pads serve multiple functions; primarily, they help in stabilizing equipment by reducing the amplitude of vibrations transmitted to the surrounding environment. This is crucial in preventing potential damage to both the equipment itself and the infrastructure it operates within. For example, heavy machinery operating on uneven surfaces can generate significant vibrations, leading to wear and tear over time. By installing vibration pads, operators can extend the lifespan of their machines and minimize the need for costly repairs.

The materials used in making vibration pads are typically engineered rubber or other elastomers, known for their excellent vibration-dampening properties. These materials can withstand various environmental conditions, making them suitable for both indoor and outdoor applications. Additionally, vibration pads are often designed with specific hardness and thickness levels tailored to different equipment types and the extent of vibrations they produce.

equipment vibration pads

Another important aspect of vibration pads is their ability to minimize noise pollution. Machinery often generates considerable sound along with vibrations, which can be a nuisance in industrial settings or urban environments. Using vibration pads not only reduces mechanical vibrations but also helps in lowering noise levels, creating a more pleasant working environment.

Installation of vibration pads is generally a straightforward process, typically involving placing the pads beneath the machinery’s feet or mounting points. Proper alignment and securing are essential to achieve optimal performance. Moreover, regular inspections and maintenance of these pads are recommended to ensure that they remain effective over time.

In conclusion, equipment vibration pads are a crucial component in any industrial setup where machinery is involved. By effectively reducing vibrations, these pads help enhance equipment stability, extend operational lifespan, and minimize noise pollution. Investing in high-quality vibration pads is a proactive measure that can lead to significant long-term benefits for businesses, ensuring that their operations run smoothly and efficiently. As technology and materials improve, we can expect even more innovative solutions in the realm of vibration management.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS