دېكابىر . 07, 2024 07:20 Back to list

check valve assy

Understanding Check Valve Assemblies Functionality and Importance

A check valve assembly, often referred to simply as a check valve, plays a crucial role in fluid control systems across various industries. These devices ensure that fluid flows in only one direction, preventing backflow which can cause contamination and damage to equipment. In this article, we will delve into the components and functions of check valve assemblies, their types, applications, and maintenance considerations.

What is a Check Valve Assembly?

At its core, a check valve assembly consists of a body, a closure mechanism (typically a disc or ball), and seats that maintain a seal. When fluid flows in the intended direction, the force pushes the closure mechanism away from the seat, allowing the fluid to pass. Conversely, when there is reverse flow, the closure mechanism returns to its seat, creating a seal that prevents backflow.

Types of Check Valves

Check valves can be categorized into several types based on their design and operational characteristics

1. Swing Check Valve This type utilizes a swinging disc that pivots on a hinge. When fluid flows in the correct direction, the disk swings open. If the flow reverses, gravity pulls the disc back into its seat to prevent backflow.

2. Lift Check Valve These valves feature a rising disc that moves up and down vertically. Fluid flow forces the disc upwards, while reverse flow causes it to drop back into the seat.

3. Ball Check Valve In this design, a ball sits in a seat. When fluid flows in the forward direction, it pushes the ball away from the seat. If the flow reverses, the ball rolls back, sealing off the passage.

4. Diaphragm Check Valve This type employs a flexible diaphragm to open and close the flow path. When fluid flows forward, it pushes the diaphragm up; if flow reverses, the diaphragm closes against the seat.

Applications of Check Valve Assemblies

Check valves are utilized in various industries including

- Water and Wastewater Treatment These valves prevent backflow of contaminated water into clean supply lines.

- Oil and Gas Check valves are essential in preventing backflow in pipelines and maintaining pressure in systems.

check valve assy

- HVAC Systems They help maintain proper airflow and prevent backflow which can disrupt heating and cooling efficiency.

- Pharmaceutical and Food Industries Here, check valves ensure that product integrity is maintained by preventing cross-contamination

.Importance of Check Valve Assemblies

The significance of check valve assemblies cannot be overstated. They help safeguard systems against leaks and contamination, thus protecting the integrity of the process and ensuring compliance with safety and environmental standards. Their operation is critical in maintaining consistent flow rates and preventing system pressure loss, which can lead to equipment failure.

Additionally, by reducing the risk of backflow, these valves help to extend the lifespan of pumps and other components, ultimately resulting in cost savings for businesses.

Maintenance Considerations

Regular maintenance of check valve assemblies is imperative to ensure optimal performance. Here are some guidelines

- Inspect Regularly Periodic checks for wear, corrosion, or damage can help identify potential failures before they happen.

- Cleaning Accumulated debris can hinder the operation of check valves. Regular cleaning, especially in systems that handle dirty fluids, is essential.

- Testing Routine testing under actual operating conditions helps verify that the valve is functioning as intended.

- Replacement If a check valve shows signs of failure or is unable to maintain a proper seal, it should be replaced promptly to avoid system failures.

Conclusion

In conclusion, check valve assemblies are integral components in various fluid systems, playing a vital role in maintaining efficient operation and preventing backflow. Understanding their types, applications, and maintenance requirements allows operators to maximize their effectiveness and reliability. As industries continue to evolve, the demand for high-quality check valve assemblies remains strong, underscoring their importance in modern engineering and process management.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

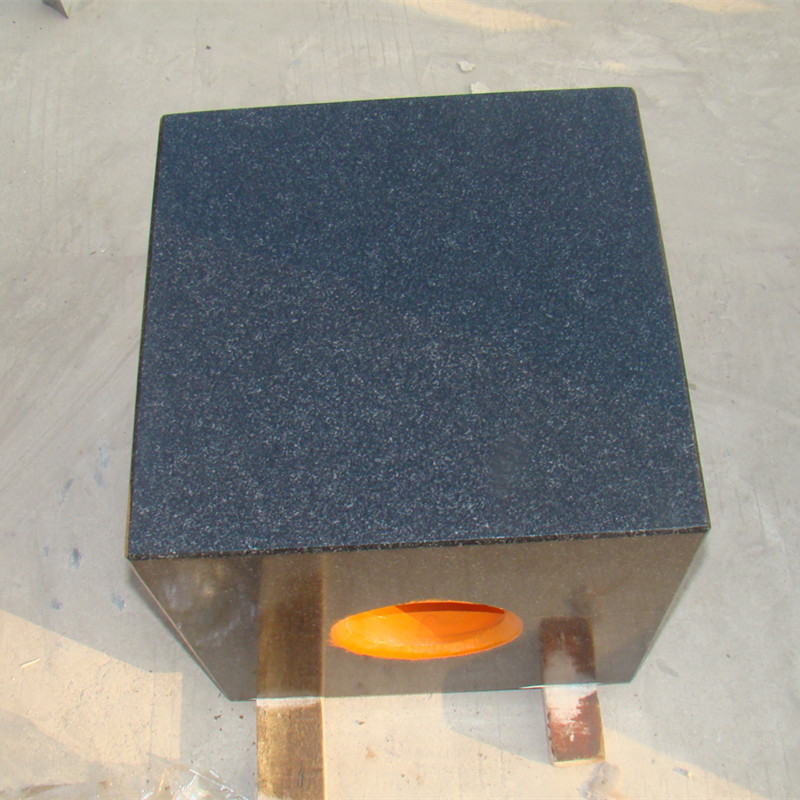

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS