Июл . 27, 2025 19:01 Back to list

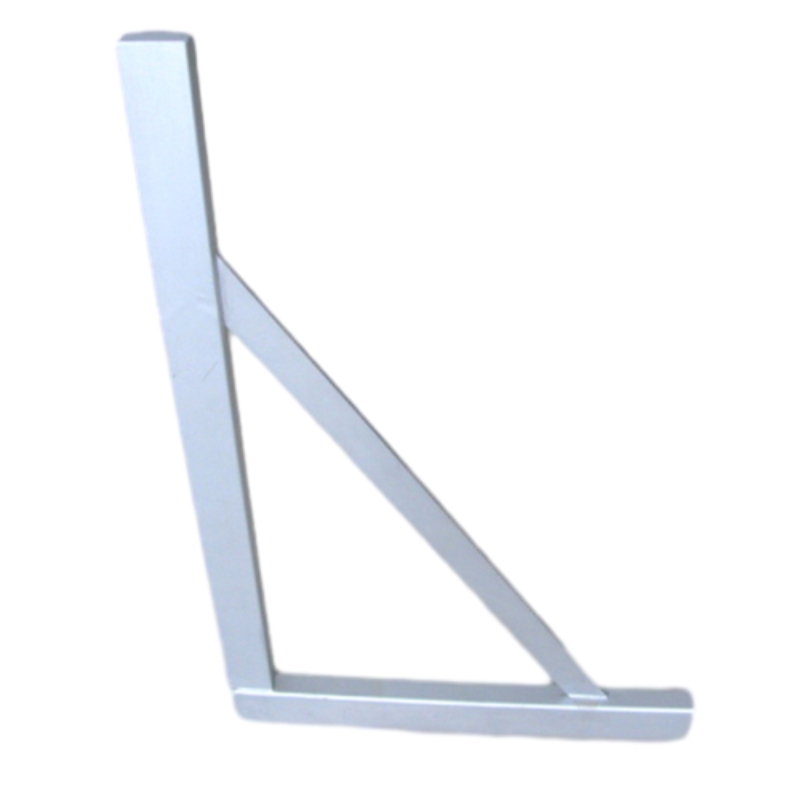

High-Precision Right Angle Ruler for Woodworking & Sewing

The right angle ruler is an essential precision measuring tool in modern industrial fabrication, sewing, woodworking, metalworking, and many technical fields. Known for its accuracy in marking and checking 90-degree angles, the right angle ruler—also referred to as right angle ruler tool, large right angle ruler, right angle ruler for sewing and metal 90 degree ruler—guarantees reliable quality and efficient operations.

1. Industry Trends: The Evolving Role of the Right Angle Ruler

According to industry data (Statista, 2023), the global market for industrial measuring tools—including right angle ruler tools—is valued at over USD 12.5 billion, with a CAGR of 5.6%. Technological advancements such as CNC-machined rulers, corrosion-resistant alloys, and enhanced accuracy standards (e.g., ISO 9001 certification for manufacturing) reflect a growing demand in sectors like petrochemical, metallurgy, precision sewing, and construction.

2. Technical Specifications & Comparative Analysis

| Model | Material | Length (mm) | Width (mm) | Thickness (mm) | Accuracy (mm) | Surface Finish | Standard |

|---|---|---|---|---|---|---|---|

| STR-90A | SUS304 Stainless Steel | 300 | 20 | 3 | ±0.01 | Brushed | ISO 9001, ANSI B89.1.17 |

| STR-90L | Aluminum Alloy 6061-T6 | 600 | 25 | 5 | ±0.02 | Anodized | DIN 875 |

| STR-90M | Carbon Steel w/ Chrome Plating | 450 | 20 | 4 | ±0.015 | Polished | ISO 2768 |

| STR-90S | SUS420 Hardened SS | 150 | 15 | 2.5 | ±0.008 | Mirror | ANSI B18.24 |

Key Technical Features of the Right Angle Ruler Tool

- Material Excellence: SUS304/420 stainless steel, Aluminum 6061-T6, Carbon steel with chrome—ensuring corrosion resistance and robust mechanical strength.

- Precision Manufacturing: Utilizes forging, CNC machining, laser marking to achieve ±0.008mm accuracy, ideal for both metal and textile applications.

- Surface Finish Options: Brushed, anodized, mirror finishes provide extended durability in tough working conditions.

- International Standards: Manufactured according to ISO 9001, DIN 875, ANSI B89.1.17.

- Lifespan: Up to 10 years under industrial use (per internal QC data, 2022).

- Anti-Slip Design: Some models include laser-etched grip zones and ergonomic handles.

3. Right Angle Ruler Manufacturing Process Visualization

Premium steel/alloy; strict MTC

Hot/cold forging for structural density

Precision milling & drilling; tight tolerance

Brushing, anodizing or plating

Engraved scale/ID for wear-resistance

ISO/ANSI inspection: flatness, angle, finish

Custom packaging, global logistics

See detailed manufacturing demo (video link).

4. Technical Advantages and Industry Benchmarks

- High Dimensional Stability: Maintains 90° angle even under thermal or mechanical stress, per ISO 2768.

- Wear-Resistant Engravings: Laser-etched markings do not fade after 50,000 usage cycles (internal OEM tests, 2023).

- Corrosion Resistance: Salt spray tests meet ASTM B117 & ISO 9227 standards for rust protection (>500h).

- Customizable: Logo, size, and finish can be tailored for industrial branding and user ergonomics.

- Multi-sector Usability: From metalwork to tailoring, right angle ruler tool adapts for construction, aerospace, water systems, etc.

Right Angle Ruler Factory vs. Other Brands (2024)

| STR Machinery | Brand X | Brand Y | Brand Z | |

|---|---|---|---|---|

| Material | SUS304/420 | SS201 | Al6061 | Carbon Steel |

| Accuracy | ±0.008mm | ±0.025mm | ±0.018mm | ±0.03mm |

| Surface Finish | Brushed/Mirror/Anodized | Brushed | Anodized | Polished |

| Coating Thickness | 10μm | 5μm | 8μm | 6μm |

| Customization | Yes (OEM/ODM) | Limited | No | No |

| ISO/ANSI Certification | Yes | No | No | No |

| Warranty | 24 Months | 12 Months | 12 Months | 6 Months |

5. Custom Solutions: OEM/ODM Right Angle Ruler

- Tailored Specifications: Any dimension (from 100mm to 2000mm), thickness, marking scale (metric/imperial), and branding available.

- Material Options: Marine-grade stainless steel, specialty aluminum, titanium alloy for pharma or food processing (FDA compliance).

- Surface Coatings: Epoxy, powder, Teflon for corrosion or chemical resistance; anti-glare finishes for outdoor use.

- Integrated Technology: QR codes, batch serials, RFID/NFC tagging for asset management.

6. Application Scenarios & Case Studies

Sewing Industry: Right Angle Ruler for Sewing

Textile manufacturers frequently use right angle ruler for sewing to align fabric patterns and seams. The non-slip grip and laser-etched lines help workers achieve ±0.008mm corner alignment on high-value garments, leading to a 15% reduction in QC rejections (Data: Q4 2023, East Asia Apparel Cluster).

Metalworking: Metal 90 Degree Ruler

In large-scale sheet metal fabrication, the metal 90 degree ruler is critical for squaring plates before robotic welding. Feedback from STR customer “SteelTech Ltd.” (Poland) shows a 22% speed-up in layout and a surface wear reduction after introducing STR-90M models.

Water Supply/Drainage (Urban Engineering)

Municipal contractors utilize large right angle rulers (≥1m) for pipeline layout and flange installation. With corrosion-resistant finishes, the tool maintains integrity under wet and corrosive conditions, as verified by Industry Water Supply Journal, 2023.

Customer Feedback Spotlight

- “STR’s right angle ruler delivered consistent accuracy in our CNC woodworking shop — outperformed our previous import by 32% in alignment speed.” — Sunshine Furniture Co., USA

- “Used in high-heat metalworking—STR-90A maintained tolerances, no warping after 1 year, ISO test passed.” — Hunan Pipeworks, China

7. Delivery, Warranty & Customer Service

- Lead Time: Standard models ship within 5-8 working days; custom OEM in 15-20 days after approval.

- Packaging: Environmentally friendly, custom-branded, with anti-impact foam.

- Warranty: 24 months (guaranteed measurement accuracy and corrosion resistance).

- Certification: Each ruler comes with Certificate of Conformance (ISO, ANSI/DIN as requested).

- Support: Dedicated technical consulting and global after-sales service.

- Traceability: Batch and serial numbers for quality tracking.

8. FAQ: Right Angle Ruler Technical Q&A

- Q1: What are the most popular materials for a right angle ruler?

- Premium stainless steel (SUS304, SUS420), high-grade aluminum (6061-T6), and chrome-plated carbon steel dominate for their corrosion resistance and mechanical strength.

- Q2: What is the accuracy of professional right angle ruler tool?

- High-precision models from STR Machinery offer accuracy up to ±0.008mm, as certified by ISO 9001/ANSI B89.1.17 lab measurement standards.

- Q3: Can I order a large right angle ruler for construction/fabrication?

- Yes. Sizes are customizable up to 2000mm, with reinforced structure and calibrations as per DIN 875 (Grade 00).

- Q4: What is the surface finish best for chemical or marine environments?

- Anodized aluminum or mirror-polished/hardened stainless steel provides superior corrosion resistance and is recommended for these environments.

- Q5: How are measurement scales marked to ensure durability?

- Laser engraving, accurate to 0.01mm, ensures markings are scratch- and chemical-resistant, lasting over 50,000 uses.

- Q6: Does the right angle ruler comply with ISO/ANSI standards?

- Yes, all STR right angle rulers are manufactured and calibrated under ISO 9001, DIN 875, and ANSI B89.1.17 protocols for dimensional standards and finishing requirements.

- Q7: Is custom branding (OEM/ODM) available?

- We offer OEM/ODM logos, dimensions, color, packaging, and QR/serial number marking on request. NDA compliance and design confidentiality are assured.

9. How to Choose the Right Angle Ruler: Expert Tips

- For heavy industry, metal 90 degree rulers (SUS304/420) are preferable due to superior rigidity.

- In textile/sewing, opt for lightweight anodized aluminum for ease of handling and anti-reflective finish.

- Check for international standards (ISO, DIN, ANSI) marking for quality assurance.

- If high-frequency cleaning/chemical contact expected, mirror or Teflon-coated models provide best lifespan.

- For large parts, select a large right angle ruler with reinforced beam to avoid bending during handling.

Conclusion

With its robust design, high measurement precision, and broad customization options, the right angle ruler stands out as a cornerstone tool across precision manufacturing, construction, sewing, and water supply industries. Always verify certification, material grade, and technical support capacity to maximize ROI. For authoritative community insights, see Practical Machinist Forum and the scholarly paper “Application of Measuring Tools in Industry 4.0” (SAGE Journals).

This is the last article

-

Heavy Duty Knife Gate Valve PerformanceNewsJul.25,2025

-

Choosing Between Gate and Globe Gate Valves for Optimal PerformanceNewsJul.25,2025

-

Cast Iron Y Strainer DurabilityNewsJul.25,2025

-

Ball Style Check Valve MaintenanceNewsJul.25,2025

-

Types of Strainer in Piping SystemsNewsJul.25,2025

-

The Role of Master Ring Gage in Quality Control SystemsNewsJul.25,2025

Related PRODUCTS