Ноя . 01, 2024 20:08 Back to list

Exploring the Features and Benefits of 8% Butterfly Valve for Industrial Applications

Understanding the 8% Butterfly Valve Applications and Importance

The butterfly valve is one of the most widely used types of flow control devices in various industrial applications. Among the varieties available, the 8% butterfly valve stands out due to its unique features and operational efficiency. This article delves into what an 8% butterfly valve is, its applications, and why it is essential in modern industries.

What is an 8% Butterfly Valve?

An 8% butterfly valve refers to a specific design concept wherein the valve is capable of regulating flow capacity with an approximate open area of 8% when fully opened. This design is particularly valuable in applications where precise control over fluid dynamics is crucial. Its disc, which rotates around a central axis, allows for quick adjustments, making it ideal for controlling the flow of liquids and gases in pipelines.

Operational Efficiency

One of the key advantages of the 8% butterfly valve is its operational efficiency. The compact design allows for quick opening and closing, thus reducing the time taken to regulate flow. This is particularly important in systems that require rapid adjustments, such as in HVAC (Heating, Ventilation, and Air Conditioning) systems or in water treatment facilities. Furthermore, the valve's lightweight construction minimizes the torque required for operation, which prolongs the life of the actuators and reduces energy consumption.

Applications in Various Industries

8 butterfly valve

8% butterfly valves are versatile and are employed across numerous sectors. In the agricultural sector, they control the flow of irrigation systems, ensuring that water is distributed evenly. In the oil and gas industry, they regulate flow in pipelines, ensuring safety and efficiency during transportation. The food and beverage industry benefits from 8% butterfly valves as well, where hygiene and precision are paramount in controlling the flow of ingredients and products.

Moreover, they play a significant role in chemical processing, where they handle corrosive materials with ease and resilience, thanks to their robust construction materials, typically made of stainless steel, PVC, or other durable substances. The water treatment sector also relies heavily on these valves for controlling the flow of water through filtration and chemical treatment processes.

Importance of Proper Selection and Maintenance

While the 8% butterfly valve offers numerous advantages, choosing the right valve for a specific application is crucial. Factors such as pressure requirements, temperature ranges, and the type of media being handled must be considered to ensure optimal performance. Regular maintenance is also essential to prevent wear and tear, which can lead to leaks or operational failures, jeopardizing safety and efficiency.

Conclusion

In conclusion, the 8% butterfly valve is an integral component in various industrial systems, offering efficiency, reliability, and precision in flow control. Its applications span multiple sectors, from agriculture to chemical processing, making it a vital tool in modern engineering. Understanding its functionality and requirements can lead to better system designs and performance, ultimately enhancing operational outcomes in various industries.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

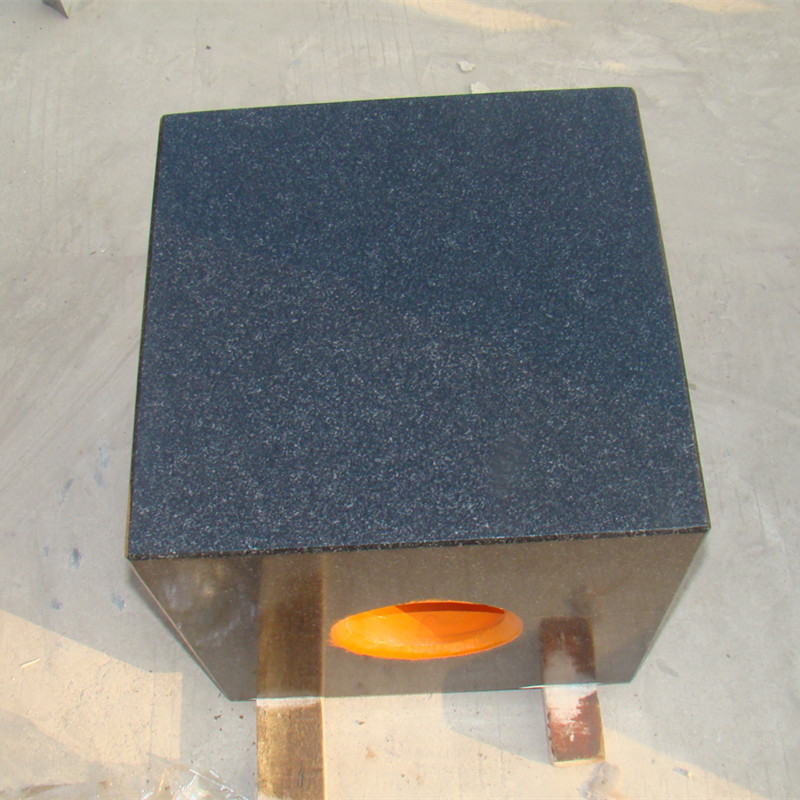

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS