Ноя . 28, 2024 10:14 Back to list

Exploring the Applications and Advantages of 2% 201% 202% Gate Valves in Industry

Understanding the 2% 201% 202% Gate Valve Applications and Benefits

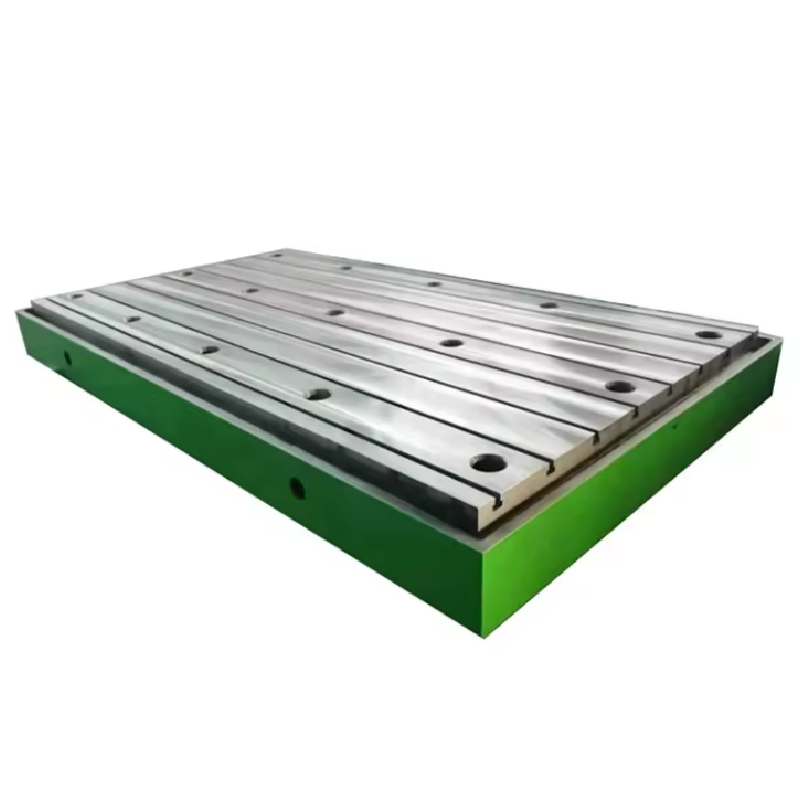

Gate valves are crucial components used in various piping systems, primarily for on-off control of fluid flow. Among the numerous types of gate valves available in the market, the 2% 201% 202% gate valve stands out due to its unique specifications and applications. This article will explore the significance, structure, and advantages of the 2% 201% 202% gate valve, highlighting why it is a necessary tool in the industry.

What is a Gate Valve?

A gate valve is a linear motion valve that opens by lifting a gate out of the path of the fluid. When fully opened, the gate valve provides minimal resistance to fluid flow and is thus a preferred choice when the intention is to either allow or completely stop fluid movement. Unlike globe valves, gate valves are primarily designed for full flow applications, hence inhibiting turbulence and pressure losses.

Features of the 2% 201% 202% Gate Valve

The designation 2% 201% 202% typically refers to specific manufacturing standards, materials used, and pressure ratings associated with the valve. Each percentage reflects a range of specifications that tailor the valve to a variety of operational settings. This classification allows for precise understanding regarding the materials, dimensions, and relevant engineering standards that govern the valve's design and functionality.

- Material Composition Gate valves can be constructed from various materials including brass, stainless steel, and carbon steel. The 2% 201% 202% gate valve is often made from high-strength alloys that ensure durability even under extreme temperatures or corrosive environments.

- Pressure Ratings The valve is engineered to withstand certain pressure levels which are critical to maintaining system integrity. These pressure ratings ensure that the gate valve can perform reliably without the risk of leakage or failure.

- Temperature Control Many industrial applications require the handling of fluids at varying temperatures. The 2% 201% 202% gate valve is designed to function effectively over a wide temperature range, making it suitable for both hot and cold fluid systems.

Applications of the 2% 201% 202% Gate Valve

Due to its robust design and high performance, the 2% 201% 202% gate valve is used across a multitude of industries including oil and gas, water treatment, chemical processing, and power generation.

- Oil and Gas Industry In this sector, gate valves are essential for controlling the flow of oil and gas in pipelines. They play a critical role in safety, allowing for quick isolation in the event of a leak or other emergencies.

2 1 2 gate valve

- Water Supply Systems Gate valves are commonly utilized in municipal water systems for controlling the distribution of fresh water. They ensure that water flow can be efficiently managed and disconnected during maintenance tasks.

- Chemical Processing For handling corrosive materials, a reliable gate valve is central to maintaining safety and operational efficiency. The materials and, in particular, the structure of the 2% 201% 202% gate valve provide the necessary resistance to chemical wear.

Advantages of the 2% 201% 202% Gate Valve

There are several benefits associated with utilizing the 2% 201% 202% gate valve in industrial applications

1. Low Operating Torque Gate valves require less effort to operate, making them easier and safer to manipulate.

2. Full Flow Capability When fully open, these valves permit a smooth flow with minimal pressure drop, improving system efficiency.

3. Versatile Use Suitable for various operating pressures and temperatures, this gate valve is ideal for diverse applications across multiple industries.

4. Longevity and Reliability Constructed from high-quality materials, the 2% 201% 202% gate valve offers long service life and ensures consistent performance.

5. Ease of Maintenance The design allows for straightforward maintenance procedures, facilitating timely repairs and reducing system downtime.

Conclusion

In summary, the 2% 201% 202% gate valve represents a key component in various industries, ensuring efficient control over fluid dynamics. With its robust design and adaptability to challenging conditions, it serves as a reliable solution for many operational needs. Understanding its features, applications, and advantages allows for better decision-making in system design and maintenance, ultimately enhancing overall productivity and safety across industrial environments.

-

thread-plug-gauge-our-promise-of-measurement-excellenceNewsAug.22,2025

-

gauge-pin-class-reflecting-quality-legacyNewsAug.22,2025

-

check-valve-types-for-high-rise-buildingsNewsAug.22,2025

-

water-control-valve-for-irrigation-systemsNewsAug.22,2025

-

gate-valve-with-soft-seal-technologyNewsAug.22,2025

-

y-type-strainer-for-oil-and-gas-applicationsNewsAug.22,2025

Related PRODUCTS