Eki . 31, 2024 22:50 Back to list

Measuring Precision with a Visual Inspection Ruler for Quality Control

Understanding the Importance of Inspection Rulers in Quality Control

In the realm of manufacturing and quality control, precision is paramount. One tool that has proven invaluable in ensuring accuracy and maintaining high standards is the inspection ruler. This seemingly simple instrument plays a crucial role in measuring the dimensions of products and components, aiding manufacturers in delivering top-quality goods to their customers.

An inspection ruler, often marked with precise measurements, is designed to provide accurate readings of lengths, widths, and heights of various objects. It serves as a fundamental tool in the inspection phase of production processes. By enabling users to measure items with precision, inspection rulers help to confirm that products meet specified tolerances and dimensions, as outlined in their design requirements.

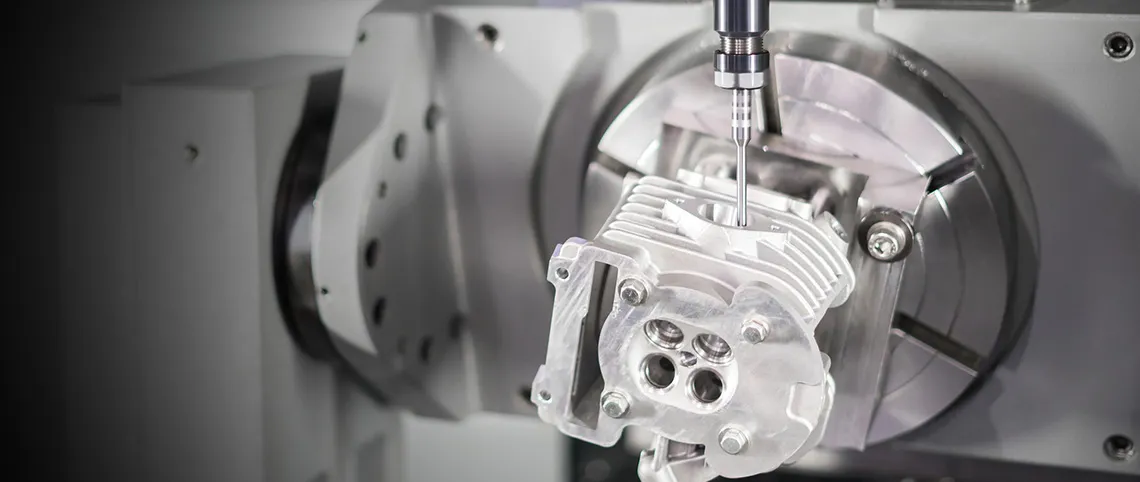

One of the primary industries where inspection rulers are extensively used is in manufacturing. In this sector, products must meet strict regulatory standards and customer expectations. For example, in the automotive industry, every component, from engine parts to body shells, must adhere to tight tolerances to ensure functionality and safety. Any deviation from these specifications can lead to significant issues, including product recalls or safety hazards. Inspection rulers allow quality control inspectors to quickly verify that parts are within acceptable limits, reducing the likelihood of defective products reaching consumers.

inspection ruler

Moreover, inspection rulers are not limited to measuring linear dimensions; they can also be used in conjunction with other measurement tools to assess angles, contours, and even depths. For example, when inspecting machined parts, engineers may utilize a combination of an inspection ruler and calipers to ensure all features of the component are within the required specifications. This multi-faceted approach to measurement enables more thorough quality assurance processes and contributes to overall product excellence.

In addition to their application in manufacturing, inspection rulers are also crucial in fields such as construction and woodworking. In these industries, precision is equally important, as inaccuracies can lead to structural failures or increased costs due to material waste. Carpenters and construction professionals rely on inspection rulers to measure lengths for cutting materials accurately, ensuring that construction projects proceed smoothly and that safety standards are upheld.

Furthermore, the advent of digital inspection tools has complemented traditional inspection rulers. Digital calipers and laser measurement devices provide more advanced capabilities and improved accuracy. However, the classic inspection ruler remains a staple in the toolkit of quality control professionals. Its simplicity, reliability, and ease of use make it a preferred choice for many.

In conclusion, inspection rulers play a vital role in maintaining quality in various industries. They not only ensure that products meet specific measurements but also protect manufacturers from potential liabilities associated with defective goods. As industries continue to evolve and embrace new technologies, the fundamental principles of precise measurement and quality control remain unchanged. The humble inspection ruler, with its critical role in verifying dimensions and ensuring product integrity, is an essential tool that will continue to be relied upon for years to come. By prioritizing precision and quality through tools like inspection rulers, manufacturers can uphold their commitments to excellence and customer satisfaction.

-

Heavy Duty Knife Gate Valve PerformanceNewsJul.25,2025

-

Choosing Between Gate and Globe Gate Valves for Optimal PerformanceNewsJul.25,2025

-

Cast Iron Y Strainer DurabilityNewsJul.25,2025

-

Ball Style Check Valve MaintenanceNewsJul.25,2025

-

Types of Strainer in Piping SystemsNewsJul.25,2025

-

The Role of Master Ring Gage in Quality Control SystemsNewsJul.25,2025

Related PRODUCTS