Nov . 14, 2024 06:35 Back to list

welded globe valve

Understanding Welded Globe Valves Design, Applications, and Benefits

Welded globe valves are a critical component in various industrial applications, known for their reliability and efficiency in controlling fluid flow. This article delves into the design, applications, and advantages of welded globe valves, providing a comprehensive overview for professionals in the field.

Design Features

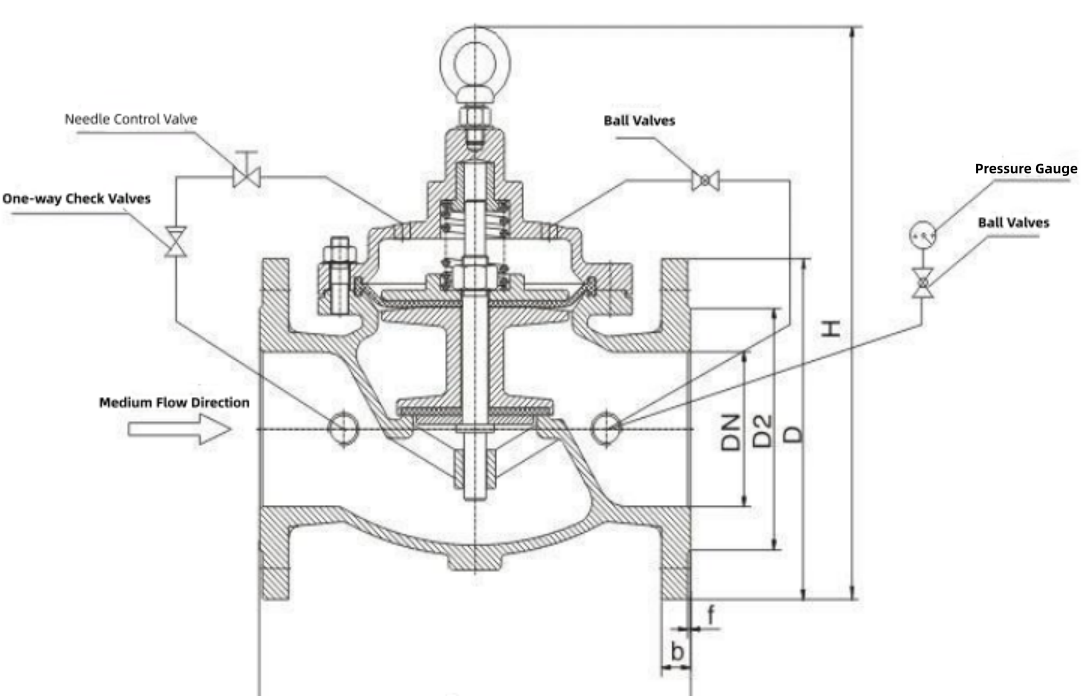

Welded globe valves are designed with a distinctive globe-shaped body that enables effective regulation of flow. The primary function of a globe valve is to throttle flow, making it ideal for applications that require precise control. Unlike gate valves, which are designed for fully opened or closed positions, globe valves are perfect for applications requiring adjustment.

The construction of welded globe valves is characterized by the absence of threaded joints, which enhances their durability. Instead, the components are welded together, providing a robust barrier against leakage. The body, typically made of materials such as stainless steel, carbon steel, or alloy materials, ensures the valve can withstand high pressure and temperatures, making it suitable for harsh environments.

The flow path within a globe valve causes fluid to change direction, which can result in pressure drop; however, this design allows for greater control over flow rates compared to other valve types. The valve is operated using a screw mechanism that raises or lowers a disk to control the flow area, allowing for fine adjustments.

Applications

Welded globe valves are widely used in various industries, including oil and gas, chemical processing, power generation, and water treatment. In the oil and gas sector, these valves are crucial for regulating flow in pipelines, ensuring safety and efficiency during transport.

In chemical processing, the ability to handle aggressive fluids makes welded globe valves an excellent choice for controlling reactants and products. Their ability to withstand high temperatures and pressures is important for maintaining operational integrity in processes such as distillation and extraction.

welded globe valve

Moreover, in power generation, welded globe valves play a vital role in controlling steam and water flow within boilers and turbines

. Their reliability in high-pressure applications helps ensure the smooth functioning of power plants.In water treatment, these valves assist in managing the flow of water through various systems, including filtration and chemical dosing, thus ensuring that potable water standards are maintained.

Benefits of Welded Globe Valves

The advantages of welded globe valves extend beyond their robust construction and suitability for controlling flow. One of the significant benefits is their leak-proof feature, resulting from the absence of threaded joints. This characteristic minimizes maintenance and enhances safety by reducing the risk of leaks in high-pressure applications.

Additionally, welded globe valves offer excellent flow regulation capabilities, allowing for precise control in various process conditions. Their ability to maintain consistent flow rates makes them a preferred choice in industries where accuracy is paramount.

Durability is another critical factor. The welded design not only extends the lifespan of the valve but also reduces the risk of fatigue and failure in demanding environments. This leads to decreased downtime and repair costs, offering long-term operational savings.

Conclusion

In summary, welded globe valves are integral components across multiple industries, providing reliable flow control in a robust and durable design. Their unique features, including leak-proof construction and exceptional flow regulation, make them indispensable for applications involving high pressures and temperatures. As industries continue to evolve and require more sophisticated fluid control solutions, the importance of welded globe valves will undoubtedly continue to grow. Understanding their benefits and applications can help organizations make informed decisions, ensuring efficiency, safety, and reliability in their operations. Whether in oil and gas, chemical processing, power generation, or water treatment, welded globe valves stand out as a trusted solution in today’s dynamic industrial landscape.

-

Wear Resistance Strategies for Trapezoidal ThreadsNewsJun.26,2025

-

Selecting Thread Gauge Types for Aerospace Component InspectionsNewsJun.26,2025

-

Ring Gauge Influence on Cigar Aging Potential and Storage SolutionsNewsJun.26,2025

-

Pin Gauge Training Programs for Enhanced Dimensional Inspection SkillsNewsJun.26,2025

-

Custom Spline Ring Gauge Design for Unique Engineering NeedsNewsJun.26,2025

-

Cost-Effective Alternatives to Custom Threaded Ring GaugesNewsJun.26,2025

Related PRODUCTS