Nov . 29, 2024 17:21 Back to list

Understanding the Functionality of Pilot Check Valve in Fluid Systems

The Importance of Pilot Check Valves in Fluid Control Systems

Pilot check valves play a crucial role in fluid control systems, especially in industries like manufacturing, water management, and oil and gas. These specialized components are designed to regulate the flow of fluids while ensuring safety and efficiency in various applications. Understanding the function and benefits of pilot check valves can help engineers and operators optimize their systems for better performance.

What is a Pilot Check Valve?

A pilot check valve is a type of check valve that allows fluid to flow in one direction while preventing backflow. Unlike standard check valves, which rely solely on the pressure of the fluid to operate, pilot check valves have an additional pilot mechanism that controls their opening and closing. This pilot mechanism is generally activated by a separate source, which can be a hydraulic signal or an electronic control system.

The primary function of a pilot check valve is to ensure that fluid flows in the desired direction. In applications where backflow can result in contamination, damage to equipment, or even hazardous situations, pilot check valves serve as a vital safety measure. By providing an additional layer of control, these valves contribute to the overall reliability of the system.

How Does a Pilot Check Valve Work?

Pilot check valves incorporate two main components the check valve itself and a pilot system. When the fluid flows in the intended direction, the pressure opens the check valve, allowing the fluid to pass through. Simultaneously, the pilot system can signal the valve to close if the pressure falls below a certain threshold or if there is a reverse flow situation.

The operation of a pilot check valve can be illustrated by its two primary states the open state, allowing free flow, and the closed state, preventing backflow. The unique design facilitates quicker response times and enhanced control compared to traditional check valves. This makes them particularly suitable for applications requiring rapid fluid movement while ensuring proper regulation.

Applications of Pilot Check Valves

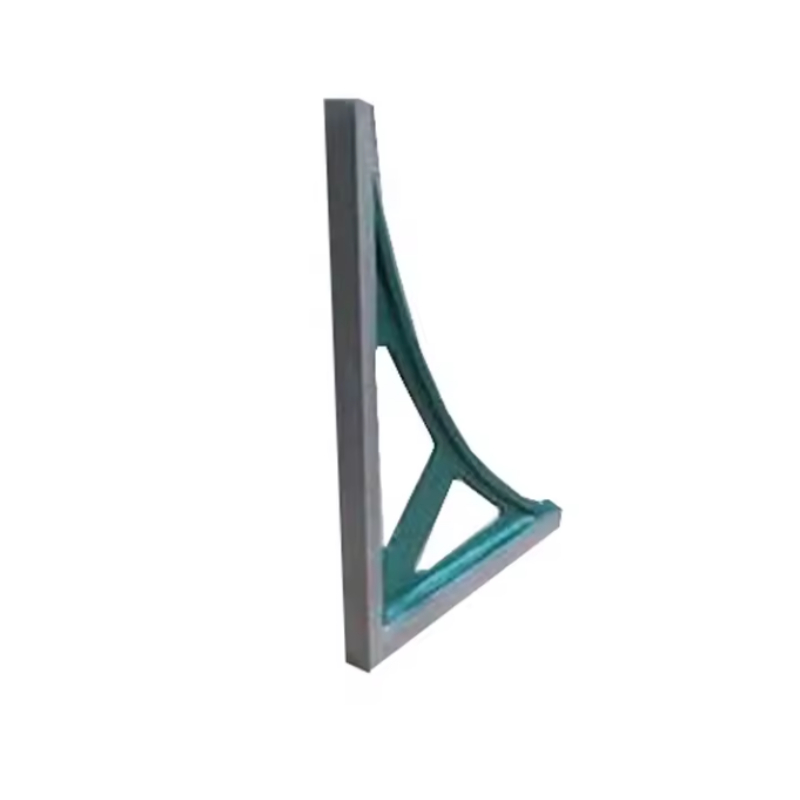

pilot check valve

Pilot check valves are utilized in a variety of applications across multiple industries. In hydraulic systems, for example, they help maintain pressure while allowing for specific operational sequences. This is crucial in machinery where timing and precision are needed to ensure safety and efficiency.

In water treatment facilities, pilot check valves prevent backflow that could result in contamination of clean water supplies. Their role in protecting quality standards in fluid conveyance cannot be overstated. Similarly, in the oil and gas sector, these valves prevent the reversal of hazardous substances, thereby safeguarding the environment and the operational integrity of pipelines.

Additionally, pilot check valves are often found in process industries where they regulate flow rates and optimize production efficiency. The ability to control multiple flow paths while preventing unwanted backflow reduces wear and tear on equipment and enhances the lifespan of the system.

Advantages of Pilot Check Valves

The primary advantages of pilot check valves include their ability to provide precise control and fast response times. Their design allows for minimal pressure drops, which improves overall system efficiency. Moreover, pilot check valves can be automatically operated and customized to meet specific operational needs, making them versatile for various applications.

Another significant benefit is the contribution to safety. By preventing backflow, pilot check valves mitigate risks associated with fluid contamination and system malfunctions. This enhances operational safety in environments where chemicals and other hazardous materials are involved.

Conclusion

Pilot check valves are integral components in the design and operation of fluid control systems. Their unique functionality offers enhanced control, safety, and efficiency, making them a preferred choice in numerous industrial applications. As industries continue to seek ways to optimize operations and ensure safety, the importance of pilot check valves will only continue to grow. Understanding their role and advantages can empower engineers and operators to create more reliable and efficient fluid control systems that meet modern demands.

-

thread-plug-gauge-our-promise-of-measurement-excellenceNewsAug.22,2025

-

gauge-pin-class-reflecting-quality-legacyNewsAug.22,2025

-

check-valve-types-for-high-rise-buildingsNewsAug.22,2025

-

water-control-valve-for-irrigation-systemsNewsAug.22,2025

-

gate-valve-with-soft-seal-technologyNewsAug.22,2025

-

y-type-strainer-for-oil-and-gas-applicationsNewsAug.22,2025

Related PRODUCTS