Dec . 26, 2024 15:33 Back to list

Leading Manufacturer of High-Quality Butterfly Valves for Various Applications

The Versatility and Importance of Butterfly Valves A Manufacturer's Perspective

Butterfly valves have gained prominence in various industries due to their unique design, efficiency, and versatility. As a leading butterfly valves manufacturer, understanding the features and benefits of these valves can guide both potential customers and industry stakeholders in making informed decisions. This article delves into what butterfly valves are, their applications, advantages, and the considerations for manufacturers in producing high-quality valves.

What are Butterfly Valves?

Butterfly valves are quarter-turn valves that use a circular disc to regulate the flow of liquids or gases through a pipeline. The disc, which is mounted on a rotating shaft, can be turned 90 degrees to either allow or restrict flow. This simple yet effective design makes them suitable for various applications, including water supply, wastewater treatment, chemical processing, and HVAC systems.

Applications of Butterfly Valves

The versatility of butterfly valves permits their use across a myriad of sectors. In water treatment facilities, for example, they are often employed to control the flow of water through treatment processes. In the oil and gas industry, butterfly valves are essential in regulating the flow of hydrocarbons, making them indispensable in pipeline systems.

Additionally, these valves are commonly used in food and beverage processing, where hygiene and efficiency are paramount. Their lightweight structure allows for quick installation, and their compact design is advantageous in systems with space constraints.

Advantages of Butterfly Valves

1. Efficiency Butterfly valves require less space than traditional gate or globe valves, making them easier to install in tight spaces. Their design allows for quick operation, providing a more efficient flow control mechanism.

2. Cost-Effectiveness The manufacturing process for butterfly valves is generally less complex, resulting in a more economical product. Their lightweight construction also leads to savings in transportation and installation costs.

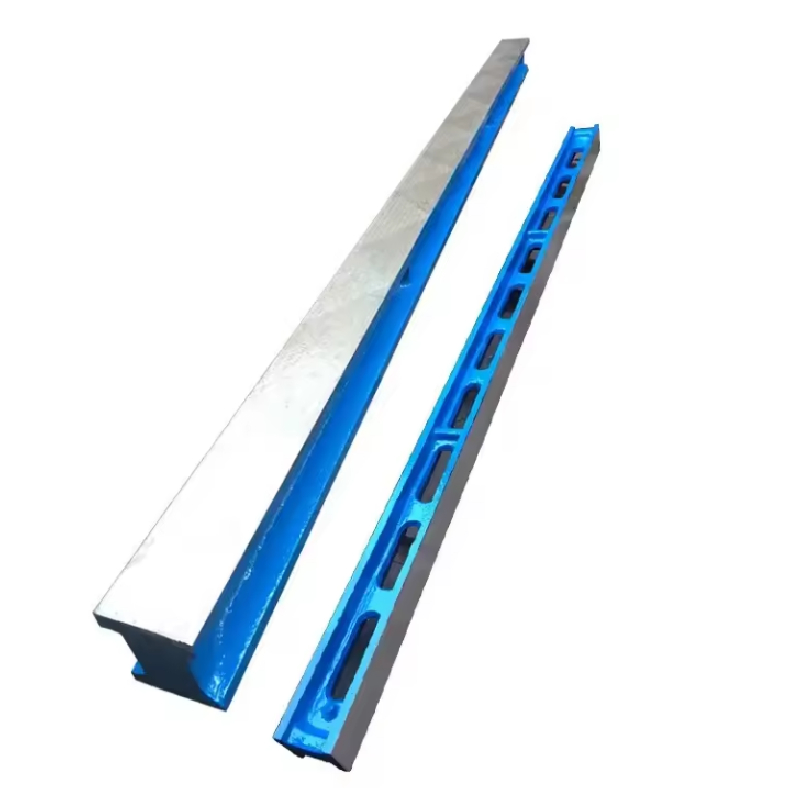

butterfly valves manufacturer

3. Durability High-quality butterfly valves are designed to withstand extreme temperatures and pressures. Materials such as stainless steel, ductile iron, and various polymers can be employed to enhance resistance to corrosion and wear.

4. Low Maintenance Once installed, butterfly valves typically require minimal maintenance. Their simple design reduces the potential for leaks and mechanical failures, which translates to lower downtime and operational costs.

5. Versatile Design Options Butterfly valves can be customized to suit a variety of operational requirements. Options such as soft seals, metal seats, and various actuation methods (manual, electric, or pneumatic) enhance their adaptability.

Considerations for Manufacturers

As a manufacturer of butterfly valves, several critical factors must be considered to ensure the production of high-quality products. First, the selection of materials is vital. Using the right materials not only enhances the valve's lifespan but also ensures compatibility with different types of fluids.

Second, manufacturers must adhere to industry standards and regulations. Compliance with certifications such as ISO, API, and ANSI guarantees that the valves meet stringent quality and safety criteria. Moreover, investing in advanced manufacturing technologies, such as precision machining and automated assembly, can significantly improve product quality and consistency.

Finally, maintaining strong relationships with suppliers and customers allows manufacturers to receive valuable feedback, which can guide product improvements and innovation.

Conclusion

Butterfly valves represent an essential component in fluid control systems across various industries. Their efficiency, cost-effectiveness, and versatility make them a preferred choice for many applications. As a butterfly valves manufacturer, prioritizing quality, compliance, and innovation is crucial for meeting market demands and ensuring customer satisfaction. By understanding the importance of these valves and their applications, manufacturers can continue to contribute to the advancement of fluid management solutions worldwide.

-

thread-plug-gauge-our-promise-of-measurement-excellenceNewsAug.22,2025

-

gauge-pin-class-reflecting-quality-legacyNewsAug.22,2025

-

check-valve-types-for-high-rise-buildingsNewsAug.22,2025

-

water-control-valve-for-irrigation-systemsNewsAug.22,2025

-

gate-valve-with-soft-seal-technologyNewsAug.22,2025

-

y-type-strainer-for-oil-and-gas-applicationsNewsAug.22,2025

Related PRODUCTS