Oct . 22, 2024 03:44 Back to list

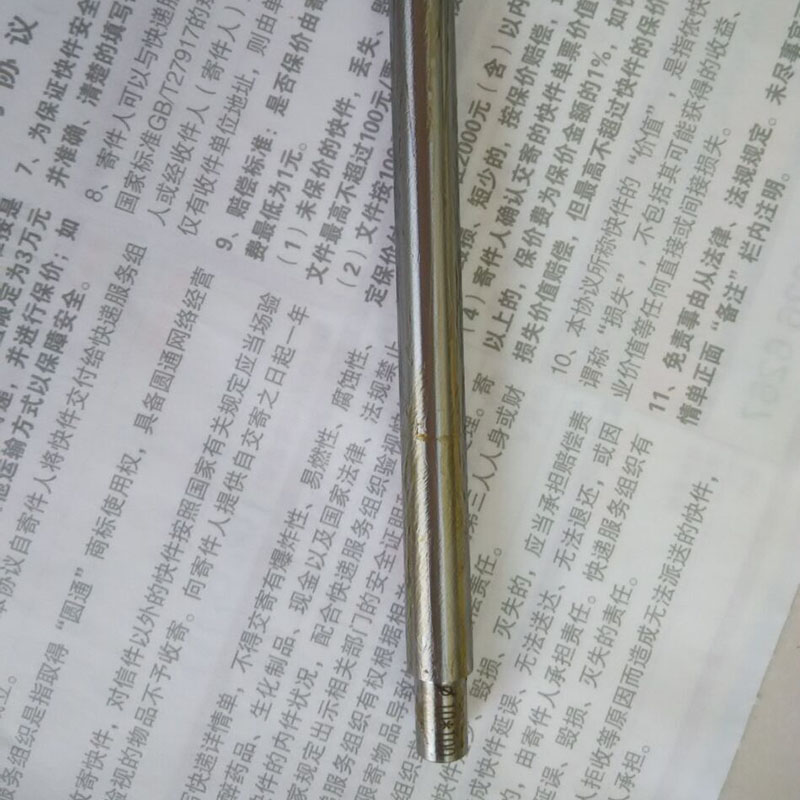

stop and check valve

Understanding Stop and Check Valves Key Components in Fluid Systems

In various industrial applications, effective fluid control is imperative for safety and operational efficiency. Two critical components that play a significant role in managing fluid flow are the stop valve and the check valve. While they serve different purposes, understanding their functionality is crucial for optimizing fluid systems in various settings.

Stop Valves

The primary role of a stop valve is to control the flow of fluid within a pipeline. Typically employed in plumbing and industrial applications, stop valves can be fully opened or completely closed. This on/off mechanism allows for maintenance activities and system isolation, ensuring that fluid flow can be halted safely without disrupting the entire system.

There are several types of stop valves, including gate valves, globe valves, and ball valves. Each type has its advantages and is suited for different applications. For instance, gate valves provide minimal resistance to flow and are ideal for services where the valve remains either fully open or fully closed. In contrast, globe valves are more suited for throttling applications, providing better control over fluid flow.

stop and check valve

Check Valves

In contrast, check valves are designed to prevent backflow in a system, ensuring that fluid flows in one direction only. This is essential in preventing reverse flow which can lead to contamination, damage to equipment, or dangerous situations in pipe systems. When fluid moves in the intended direction, the pressure pushes the valve open; however, if the flow reverses, the valve closes to stop the backflow.

Check valves come in various designs, such as swing check valves, spring check valves, and lift check valves. Each type has specific characteristics and is used based on the system’s requirements. For example, swing check valves are commonly used in applications where pressure drops are minimal, while spring check valves can operate effectively in situations where backflow needs to be stopped quickly.

Conclusion

In conclusion, stop and check valves are essential components of fluid control in numerous industrial systems. While stop valves allow for the easy control of fluid flow, check valves provide a safeguard against undesirable backflow. Understanding the functions and advantages of these valves enables engineers and operators to design more effective and safer fluid handling systems. By carefully selecting the appropriate valves, industries can enhance performance, improve safety, and reduce maintenance costs, underscoring the importance of these seemingly simple yet vital components. Whether in municipal water supply, chemical processing, or power generation, the roles of stop and check valves cannot be overstated.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS