Oct . 30, 2024 20:15 Back to list

no go pin gauge

Understanding No Go Pin Gauges Importance and Applications

In the world of precision engineering and manufacturing, the No Go pin gauge plays a crucial role in ensuring the accuracy and quality of machined components. Pin gauges are a type of measurement tool used to check the dimensions of holes, slots, and other features of parts to ensure they meet specified tolerances. The No Go pin gauge, in particular, serves as a critical checkpoint in this process.

Understanding No Go Pin Gauges Importance and Applications

The function of the No Go pin gauge is essential in industries where high precision is mandatory, such as aerospace, automotive, and medical device manufacturing. When a component is assessed with a No Go gauge, the inspector inserts the pin into the hole. If the pin enters easily, it indicates that the hole is oversized and does not meet specifications. Conversely, if the pin does not fit, the part is considered acceptable.

no go pin gauge

Using No Go pin gauges can significantly reduce the risk of defects in production. They provide a simple yet effective way to enforce dimensional tolerances and ensure that all parts will function correctly in their intended assemblies. For manufacturers, incorporating No Go gauges into their inspection processes can lead to increased efficiency, reduced scrap rates, and improved overall product reliability.

Moreover, No Go pin gauges come in a variety of sizes to accommodate different applications, and they can be made of various materials, including stainless steel and carbide, depending on the wear resistance required for the task. Regular calibration and maintenance of these gauges are essential to maintain their accuracy over time.

In summary, No Go pin gauges are vital tools in the realm of manufacturing, primarily due to their ability to ensure that components remain within designated tolerances. Their straightforward design and functionality make them indispensable in quality control measures, helping to uphold industry standards and finalize products that are both reliable and efficient. By integrating No Go pin gauges into the inspection workflow, businesses can enhance the quality of their output and foster greater customer satisfaction.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

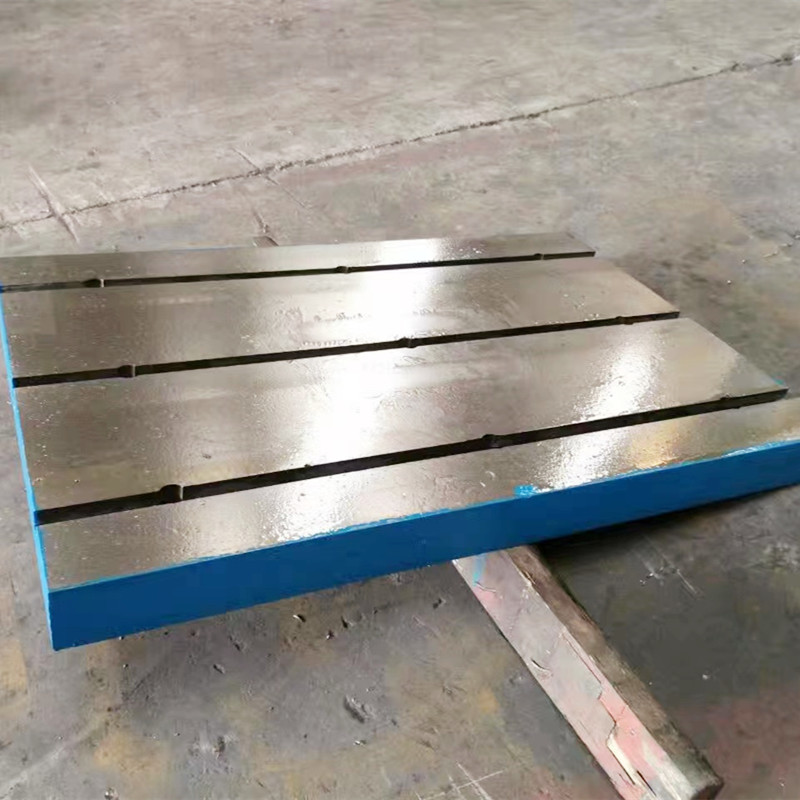

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS